Features of eccentric sander

The grinder is an indispensable tool during the renovation of various premises. With the help of such equipment, you can efficiently and quickly sand a variety of surfaces. The eccentric sander is a popular unit in a group of similar devices.

Peculiarities

The eccentric sander is designed for preparing a wide variety of surfaces to be varnished, primed or painted.

Materials that can be processed with this device:

- plastic;

- wood;

- metal;

- natural stone;

- glass.

The technique works according to the principle of rotation of a circle with two impulses: orbital and radial. ESHM makes it possible to polish planes of varying degrees of curvature and slope.

There are various types of units, each of which is designed for a specific type of work. For example, a draw frame cannot polish a surface to be varnished, but an eccentric machine can do this job without any difficulty.

When choosing a grinder (popularly called an "orbital"), it is important to pay attention to a number of important characteristics.

- The power of the unit directly depends on the energy that is consumed.

- Rotation frequency. The standard speed is 12,000 rpm. However, this figure can vary from 2,000 to 20,000 revolutions. Many devices have electronic stabilization, which reliably controls the number of revolutions.

- Platform stroke parameter (it ranges from 2 to 7 mm). The lower this indicator, the more accurate the processing will be.

- The weight. It is often necessary to work with this device at a height, keeping the machine suspended, so the weight of the machine is important.

- Disc diameters (115, 125, 150 mm).

Device and principle of operation

Before you start working with an eccentric sander, you should familiarize yourself with how it works, as well as with its modes of operation. ESHM are designed for both rough and filigree polishing of a wide variety of materials. For this, the rotating abrasive wheel performs forward and backward-circular motions.

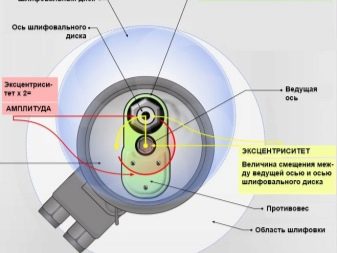

A similar tool works on a simple principle: the drive is attached to the base (sole), a removable working circle is mounted on it. The circle rotates and oscillates at the same time (this impulse is possible due to the presence of an elliptical eccentric). The rotation speed can reach 20,000 rpm. With such indicators, any materials can be processed using abrasive materials.

ESM generates increased vibration, so the presence of one or more handles on the tool is often decisive. For smaller jobs, pistol grip models may be the best choice. Such a device has classic parameters and fits comfortably in the palm of your hand. It is especially convenient with such ESM to work on hard-to-reach elements, which are often found when repairing machines.

The presence of a stopper is of great importance during the operation of the units - it allows you to automatically hold the unit in operation.

Appointment

When choosing an ESM, you should know exactly its purpose, as well as how often it will be used. If the device is used once a month (or even less often), then it is wise to purchase an inexpensive sander.In the case of professional use of ESM (for example, for construction), it is recommended to look at more expensive models.

The quality of the machine tool depends on the following indicators:

- power;

- amplitude;

- torque speed;

- machine weight;

- power supply;

- diameter of the nozzle circle;

- frequency of revolutions;

- current adjustment, etc.

ESM power is one of the main indicators. Power fluctuates from 165 watts to 950 watts. In everyday life, units are used that have a power of 300 to 600 watts. The machine can be powered from a power plant or from a 220 volt network. If you have to work at a distance from stationary energy sources, then it is better to use the battery option.

On production sites (for walls and ceilings, for plastering), a pneumatic eccentric machine is most often used. Such units are easy to use: they have a minimum of dynamic units, do not need power from an electric motor or a battery device. One of the best manufacturers of such equipment is Dynabrade, which manufactures Dynorbital machines.

An important point to remember when choosing an ESM is that the rotation speed decreases with an increase in the power of the unit. The vibration amplitude is responsible for the quality of the surface finish. There are models with an amplitude of vibration from 2 to 5 millimeters. On some models, additional attachments can be installed that will correct the reciprocating movement. Such additional devices change the dimensions of the "orbit" required for grinding.

It is also important to take into account the diameter of the sanding "pad" itself: the larger the size, the larger the area can be processed in one go. Usually, this indicator varies in the range from 120 to 155 mm, however, other sizes are also found: 75 mm, 95 mm. Small diameters of "plates" make it possible to work with corner joints.

Devices with small diameters are exclusive products. Such units are produced by only a few companies: Rupes, Metabo.

There are special ESM with a horizontal layout of the engine, which has forced rotation.

Such machines are designed for combined work, therefore they are most often used by professional builders.

Views

ESM are classified according to several criteria:

- machines with which you can work on wood or metal;

- ESM, which operate from the electrical network or from batteries;

- professional models and devices for household needs;

- miniature units with speed control and large pneumatic ESM.

ESM are capable of making surfaces perfectly smooth. The quality of the "orbital" operation is achieved with the help of the oblique-rotational movement of the canvas itself. At high speeds (more than 10,000 thousand per minute), a large amount of energy is generated, which is transferred to vibration. It is transformed into a force impulse, thanks to which the polishing process takes place. The eccentric needs a counterweight, which is necessary to smooth out excess vibration.

Consider the most popular ESM manufacturers.

- Metabo company manufactures inexpensive and compact units.

- Bosch manufactures large (over 650 watts) and medium power models. The company's products are of good quality and many different additional options (rotation control, speed, etc.). This technique is most often acquired by professionals. It is quite expensive, but it is very reliable, and also has a long service life.

- ESM from the Makita company in quality they are not inferior to German units from "Bosch". The devices are ideal for work in service stations and garages. The dust removal system is especially effective on the models. Each model has its own design features. Some ESM are equipped with a speed regulator (up to 6 positions).

Now let's take a look at some of the distinctive details and functions of the devices.

- "Orbitals" for professionals are equipped with special relays that control a constant speed during operation. In this case, the torque automatically switches to afterburner mode, while the reserve power of the engine is used.

- The starting current limiting block is used for several reasons: when it is required to reduce the load, and also to avoid a rumble at the start of the engine. This device is found exclusively on professional models.

- Adjusting the sole brake is necessary for a quick stop.

- 90% of ESHM have a socket that allows you to connect a vacuum cleaner (sometimes a vacuum cleaner replaces a special PVC container with a bag or paper bag).

- Professional tools are often equipped with a cover around the eccentric assembly.

- The D-arm makes it possible to work more comfortably.

- A switch with a latch is most often found in expensive professional models.

It is important to note that ESM does not have the ability to work in hard-to-reach places, since the sole of the tools has a round configuration (in such cases, a surface grinding unit is used).

Also ESM cannot be installed permanently. This is usually necessary when you need to work with small format products. If there are volumetric depressions or depressions on the workpiece, then the ESM will not penetrate there, there is also the possibility of damage to the edges by the rotating element of the machine.

Rating of the best models

The best models of electric tools for grinding various surfaces:

- Zubr 452 is a high-quality device that is inexpensive;

- Black & Decker KA-199 is ideal for working with cars;

- Hammer OSM-435 is usually used in a small workshop for commercial purposes;

- "Interskol EShM 125/27" is a very compact machine with low weight;

- Ruobi ROS300A is distinguished by high quality workmanship and fit of parts.

The best professional tools are:

- Metabo FSX-200 - compact device with low weight;

- AegEX 125 ES - the tool is suitable for commercial use;

- Bosch GEX 150 AC is ideal for small workshops;

- DeWalt D26320 is a powerful tool that can handle large volumes;

- Makita BO 6030 is the most powerful machine of all ESM presented.

Selection Tips

Modern ESM are equipped with various functionalities.

- It is important to choose the correct speed control - this function allows you to correct coarse and fine grinding, which should be done during most jobs.

- Dust collectors are also important. Some models (for example, devices from the Makita company) may have 3 protective containers for the dust collector: PVC box, rag bag, paper bag. In some models, a small vacuum cleaner is also used, which is important if you need to process large areas.

- An additional handle (often screwed on) is often in demand, it allows you to distribute mechanical pressure, which greatly facilitates the work. The ESHM of DWT company is very convenient in this respect - the models from this manufacturer are equipped with side handles that allow you to work comfortably with vertical planes.

- It is also important to have a soft start of the device, which ensures the safety of the workpiece. After a sharp start of the ESM, there is always excess vibration, which can generate defects and chips.

A gradual approach to the required speed allows the master to fully prepare for the workflow.

- The pressure indicator is also important, which makes it possible to smoothly launch the ESM. The bench force indicator makes it possible to more accurately handle equipment and workpieces.

- Abrasive retainers are important. The most popular of these is duct tape. There is also Quick-Fit, which provides block replacement.

It is important to decide on the abrasive before starting work.So, for example, there are universal abrasives that are prepared specifically for a specific workpiece: the larger the fraction of grains, the more rough the processing will be.

Important: abrasive for metal is suitable for working with wooden blanks.

One of the important points is perforation. The holes on the rig and platform, as well as on the backing plate, must be mated. This modification is not always found, so sometimes the easiest way is to buy a sheet and make holes manually.

Subtleties of application

In the course of work, you must follow simple rules.

- During the working process, you must use a vacuum cleaner.

- When assembling the ESM base, you should pay attention to the fact that the holes on the "plate" coincide with the holes on the circle.

- Correct work in the "orbital" is the ability to regulate the speed. To finish the surface of any material, do not turn on high speed.

- During polishing, do not press too much on the device - the engine will fail very quickly.

- Before completing the work, the ESM should be removed from the workpiece so as not to damage it.

- If there is excessive vibration, it is best to place your palm on the body - it softens the excess vibration.

- During long-term operation, breaks should be taken, otherwise the engine can quickly overheat and fail.

- You should do a regular preventive inspection of the tool and pay attention to the presence of grease on the dynamic elements.

- Before buying a tool, you should decide exactly what kind of work will be performed by it.

For a comparison of eccentric sanders, see the video below.

The comment was sent successfully.