Do-it-yourself wardrobe

As you know, in the modern market there are many furniture manufacturing firms that offer a wide range of products, for example, popular and necessary wardrobes. On the one hand, you can purchase such an option in any store, entrusting its assembly to experienced craftsmen. On the other hand, a self-made item is much more valuable and proud for the owner.

Let the maximum amount of time and effort be spent on this, but one cannot but agree that a do-it-yourself wardrobe will ideally meet the household needs of the owner of the house.

Determining the type

If you plan to install a cabinet in the hallway, it is important to take into account the fact that in many apartments it is small, rectangular. Unlike conventional wardrobe swing doors, sliding sliding doors will provide space-saving in the best possible way.

Maintaining free space is important in any room, not only in the corridor, but also in the bedroom, which should always remain a zone of comfortable rest and order. If the height, at the same time, is made up to the ceiling, the usually empty space will be used with maximum benefit.

In the corner zone of the living space, depending on the characteristics of its total area, an unusual and spacious radius wardrobe can be placed. Corner placement is beneficial in that the piece of furniture installed in this way will accommodate much more things than with the other option.

However, it is rather difficult to manufacture, so it is better for a novice master not to take on it, but to confine himself to a simple rectangular model.

A built-in wardrobe can be installed if there is a niche or storage room in the room. It will be functional, convenient and aesthetically pleasing. In addition, making a closet from a pantry yourself is much easier than making it completely: there are already walls, a ceiling and an interior space. The main task is to decide on the filling of such a cabinet, to correctly plan the dimensions, drawing and course of action.

Materials (edit)

The choice of materials should be carefully, first of all thinking about strength, reliability and durability.

Wood

If we are talking about wood, then it is not suitable for creating a built-in wardrobe, because the level of humidity in a niche or closet is much higher than in a room. Any tree will quickly begin to crack and lose its natural beauty. As a last resort, you can use it to create small components and decorative elements, but with the obligatory preliminary treatment with a water-polymer emulsion or drying oil.

Drywall

Recently, a very popular material is drywall. However, professional furniture assemblers do not recommend using it. This material is highly fragile and very heavy in weight.

In addition, it must be attached to some solid base.

Shelves made of plasterboard quickly begin to "sag" under the weight of things, crack and deform. You can create other pieces of furniture from it, but it is absolutely not suitable for the manufacture of a high-quality wardrobe.

Fiberboard, MDF and laminated chipboard

The best options are fiberboard, MDF or laminated chipboard.It is these materials that have always been distinguished by their strength and reliability, it is easy and simple to work with them, and humidity and temperature drops do not affect them. A large selection in the markets and in stores of various colors of laminated chipboard will allow anyone to choose the desired color.

An important point: for the purpose of manufacturing cabinets, there is a certain standard for laminated chipboard sheets with a thickness of 16 mm.

Plywood

Plywood is no less versatile and durable. It can also be laminated; on sale you can find its varieties, which are water-resistant and insensitive to high humidity, which is important when placing a wardrobe in a niche or storage room.

Plywood combines both strength and flexibility in processing because it is made from soft wood species. It should be remembered that when screwing self-tapping screws into it, it can deform, but this will not happen if you use washer-shaped gaskets.

Furniture panels

The sliding wardrobe can also be made of furniture boards. First of all, they are famous for their visual appeal and low price. This material is based on natural wood species such as oak, alder, birch. When creating furniture, panels are usually combined with plywood in the following way: the frame and facade of the structure are made from them, and shelves and boxes are made of plywood.

Standard thickness - 2 cm.

From an old cabinet that has served its time, you can make elements that may be needed when creating a new one. Sometimes chipboard sheets in old-fashioned furniture are extremely durable: unlike many modern materials, it is impossible to even screw in screws into them without first creating a special hole. In this case, old but strong chipboard panels will ideally fit inside the cabinet as solid shelves.

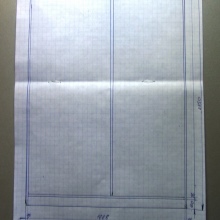

If the suitable material has already been chosen, it remains to purchase ready-made sliding doors for the future cabinet. Of course, you can make them yourself, but this will cost much more than purchasing doors that are already ready for installation. You should find a good company that manufactures sliding doors, and place an order there, indicating the dimensions of the opening and the number of panels.

In order for the sliding doors to serve as long as possible, it is imperative to purchase a self-adhesive seal. Its main purpose is not only to fasten profiles in grooves. If the seal is of good quality, it will prevent dust from entering, and the cabinet doors will move absolutely silently.

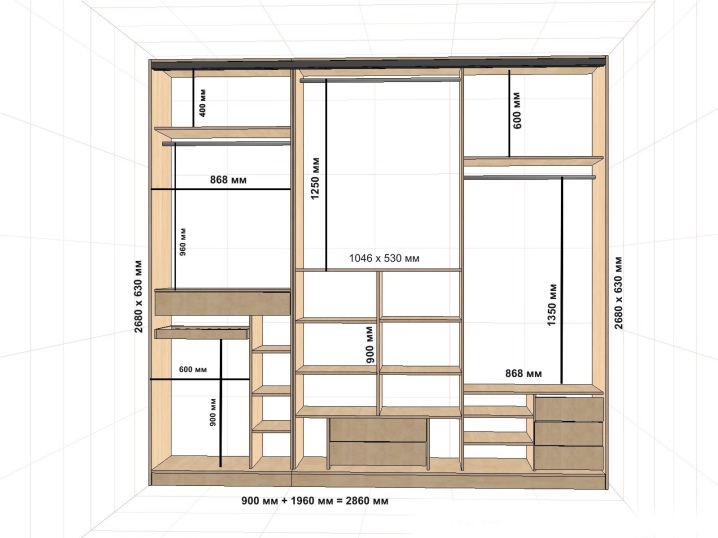

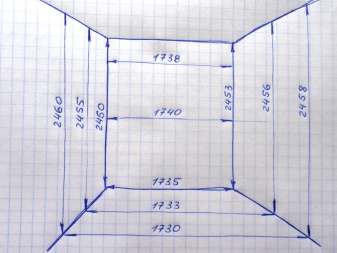

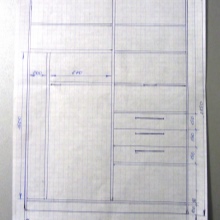

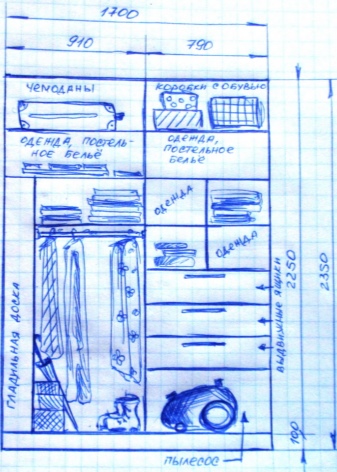

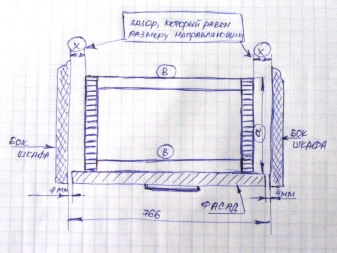

Description of drawings

Before starting the assembly of any piece of furniture, it is necessary to create a certain scheme in the form of a drawing. The dimensions should be carefully checked, with the obligatory indication of all parameters, both the outer side and the inside of the structure, while always indicating the thickness of each partition.

When drawing up a drawing, it is important to observe certain dimensional standards in advance: for example, it is recommended to leave the optimal distance between the shelves at 30-40 cm, and the depth of the drawer should be no more than 50-55 cm.

Before creating a drawing, you need to decide on the main characteristics that the future wardrobe will have:

- height, width and depth;

- the height of the mezzanines, if planned;

- how many doors, drawers and other departments will be in the closet;

- what kind of filling is planned: boxes, rungs, shelves, etc.

After that, a sketch of the future cabinet is drawn. If you have experience and the ability to draw, you can make a drawing yourself, just using a sheet of paper. There is also a simple solution for those who are not good at drawing: special computer programs, into which it will be enough only to enter certain data, and the computer will produce a ready-made full-fledged drawing. The quality and accuracy of such a drawing is so high that with its help you can safely start assembling the cabinet yourself.

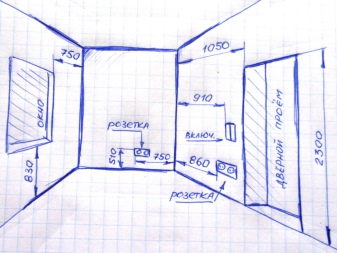

Next, a small guide is offered with which you can independently make a small built-in wardrobe at home, placed in a small niche in the hallway.

Step-by-step instruction

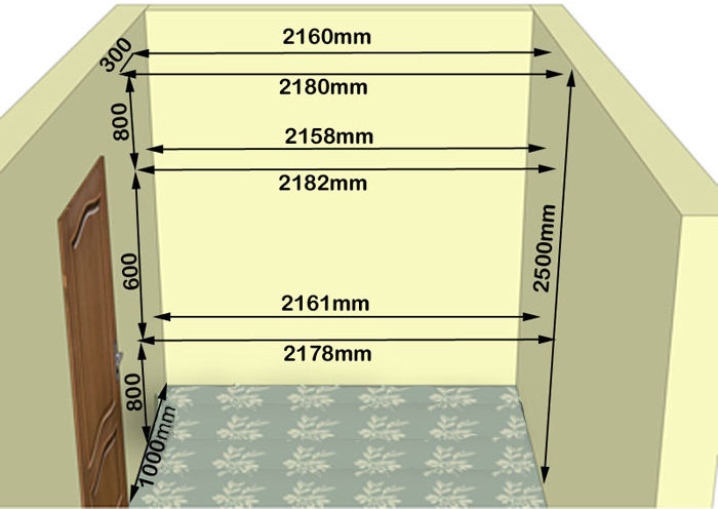

Room measurements and calculation

First, using a tape measure, three horizontal dimensions of the niche are determined on the outside: above, in the middle and below. Then the same three measurements are taken along the back wall. This is necessary in order to understand what size the future shelves will have to cut out. Further, similar dimensions (in front and along the back wall of the niche) are removed vertically in height: left edge, middle and right edge.

This helps to understand what the overall size picture will be.

It is important to remember that measurement errors are quite common. It is due to the quality of building the house and leveling the walls. The dimensions with all errors should be written in the drawing in order to make the calculations as accurately as possible.

At this stage, you need to finally decide on the detailing of the cabinet. What and where will be located, how many sliding facades are planned to be installed, how many departments there are, whether there will be open corner shelves in the closet, whether a visor with illumination is needed.

Since we are talking about a small cabinet, which is located in the hallway, you can immediately decide what and where to put. Outdoor shoes can simply be placed on the floor in a niche, without using chipboard or other material shelves. It is also advisable to think over the internal filling of the cabinet in advance: the number of compartments for clothes, drawers, shelves, rods for hangers.

All measurements should be carried out without fail taking into account the thickness of all materials used.

It is important not to forget to carefully measure the dimensions between the shelves. If the niche is curved, then the shelves will need to be made with an allowance in order to accurately fit the dimensions of the walls. The dimensions of each part should be painted, taking into account the plastic edge (PVC, usually 2 mm).

It's good if the installation takes place quickly, without unnecessary adjustments.

Sawing and fittings

With a strong desire, you can cut out the details yourself, but there is no need for this. It is better to give the finished drawing to the production workshop, where all the components for the cabinet will be made exactly according to the specified dimensions. Therefore, the drawing must be drawn up as accurately and correctly as possible, and at a proven reliable furniture factory, all the necessary elements for the upcoming assembly will be cut with high quality.

As for the accessories, there will be no problems with its acquisition now either: it is presented in a large assortment in large construction or specialized stores. Here is a rough list of what you might need when making a simple built-in cabinet:

- debell and self-tapping screws,

- spacers for soft installation of self-tapping screws,

- furniture corners (preferably metal),

- a hanger bar with rod holders (if the cabinet is small, one will be enough),

- hooks, clips for fastening shoe shelves.

Construction assembly and installation

Since this is not a cabinet, but a built-in wardrobe, the top and side panels of which replace the walls, you can start right away by determining the place for the shelves. Several marks are made on the wall with a pencil, and the shelves themselves are fastened using mounting corners.

It is better if they are metal, not plastic: the first and strong, and look very aesthetically pleasing from the outside. The corners are attached with debels and self-tapping screws.

If there are shelves in the cabinet, the length of which exceeds 800 mm, they need additional fastening, otherwise, over time, any material can bend under the weight of things. Therefore, along the back wall, the shelves should be reinforced with metal corners.

The hanger bar is attached to the wall using special round bar holders. Each of them has three holes, and fastening to the wall is carried out with debels and self-tapping screws.

At the bottom, you can install a mesh-type shoe rack. It is attached with the help of special hooks or clips, set to the desired level after preliminary marking with a pencil its location.

Then you need to fix the shelf along the side front walls with metal corners.

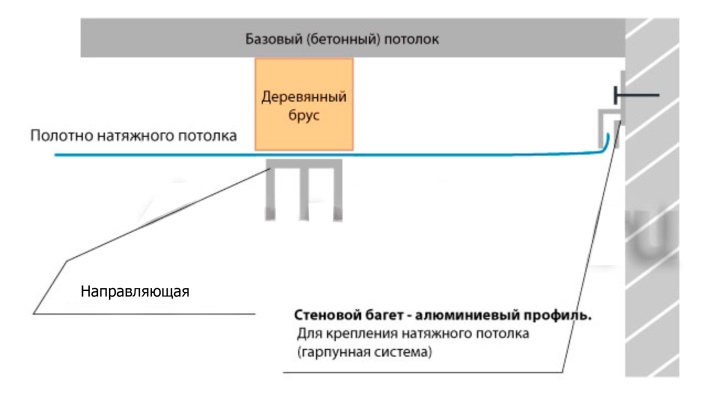

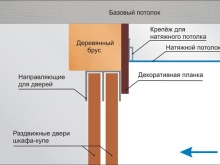

If there is a stretch ceiling in the room, in order to correctly combine such a ceiling and a wardrobe, you will need to put a mortgage between them in the form of a bar up to 100 mm wide.

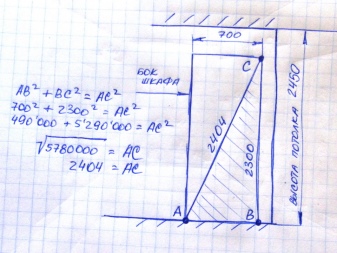

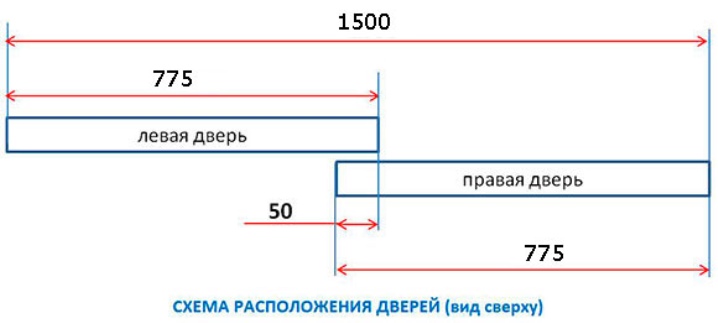

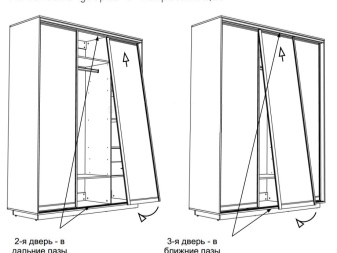

Installation of doors with guides

As already noted, the ceiling is not always even and perfect. Therefore, the primary task when installing the upper guide for sliding doors is to align and align it clearly horizontally. To do this, you will need to lay between the guide and the ceiling pads of various thicknesses.

You can make them from MDF. The resulting gap in the conclusion is closed with a frieze made of chipboard with a thickness of 8 mm.

Now you need to measure the height of the niche on the left and right in order to calculate the possible slope of the floor or ceiling, as well as the blockage of the walls. Having established the difference in size, you need to take the MDF gaskets again and put them between the guide and the ceiling. Only now, after all the installed spacers, can the upper guide be finally fixed. Drill a hole in the ceiling, hammer in a dowel, then the guide is finally attached to the ceiling with self-tapping screws.

When trying on a frieze, it is important to make allowances in order to fit all parts to size already during installation. Attach the frieze to the gap, mark the necessary lines with a pencil and cut along them. You can glue the frieze to the rail using double-sided tape. In order for the adhesive tape to adhere well, it is necessary to first degrease the glued surface with alcohol. Then glue vertical strips of adhesive tape to the surface, remove the protective film from it and glue the frieze to the upper guide.

The bottom rail for the cabinet doors is also attached with double-sided tape. This will ensure its smooth and smooth running - the doors will move silently, with minimal wear on the rollers. The doors themselves need to be inserted into the ready-to-use upper and lower guides and adjusted.

Detailed instructions for assembling and installing compartment doors can be seen in the following video.

Interesting solutions

To go beyond the standard rectangular shapes of your cabinet, you can use your creative savvy when working with materials as soft and pliable as plywood. You can create a smooth and unusual shape of a shelf or other element of a piece of furniture by moistening a sheet of plywood with water and placing it on a special shape - a blank. Within 12-14 hours, the sheet will acquire the desired smooth outlines and will be ready for use.

In addition, there is the simplest and most straightforward way to attach cabinet shelves using pieces of the most common baseboard. The MDF skirting board is distinguished by increased strength, sometimes not inferior in reliability to metal fittings. In order for such shelf fasteners not to be too conspicuous, the plinth piece can be made one third shorter than the shelf depth, and its end can be cut obliquely.

The self-tapping screw farthest from the edge of the shelf, in this case, will have to be tightened from above, through the shelf board.

The use of stained glass technology for decoration

The door panels of the wardrobe can be decorated with stained glass. The cost of manufacturing such facade decorations is different, it directly depends on the degree of complexity of the technology used. In any case, inexpensive options for stained glass cabinetry will also look great, but provided they are of high quality production.

There are three main types of stained-glass windows that are most often used for decoration:

- Classic stained glass window. It will look best with a wooden or metal frame. Glasses can be with any pattern or different colors. The process of making such a stained-glass window is very labor-intensive, which provides it with both prestige and a rather high price.

- Tiffany. Its difference from the classic stained-glass window is that it is possible to use this option if there is no frame on the facade. In this case, the drawing is more intricate and original. Technically, it is no less complex than the classic, but aesthetically very beautiful. Even its apparent fragility may not be considered a serious disadvantage compared to beauty.

- Filled type of stained glass. It is also called contour. One of the popular imitations of an expensive Tiffany made on a large glass canvas. Such a stained-glass window, due to its simpler manufacturing technique and low price, is the most popular among consumers. It is resistant to external damage and very practical, which allows it to be successfully used when decorating the simplest furniture options.

Sandblasted mirrors

If the front of the wardrobe is made in the form of a mirror coating or glass, you can apply a beautiful sandblast pattern to it. This is an abrasive type of surface treatment using sand sprayed using a special apparatus under a certain air pressure.

This technology provides any furniture with unique and realistic drawings that have volume and texture. Once upon a time, when there were no sandblasting machines, in the ancient Roman Empire, a similar glass processing was carried out by hand using a flat stone: they rubbed sea sand over the surface of the glass.

Sandblasted images are porous and unfortunately can easily get dirty. This is its only drawback that can be dealt with by protecting the surface of the drawing with varnish or a special solution containing polymer components.

Vinyl stickers

An excellent and easiest way to decorate the facade of a wardrobe, if there is no financial opportunity to order stained glass or sandblasting decoration. Usually, these stickers look like transparent wallpaper. In their manufacture, a special film is used. Thanks to its transparency and solid color pattern, you can easily match the sticker to the color of any cabinet.

Change the old bored sticker to a new one at any time - it can be easily removed without leaving marks on the mirror or glass.

Thus, thanks to modern technologies, it is possible to apply many interesting solutions for both practical and aesthetic design of the wardrobe. Even with minimal financial investments, but in the presence of ingenuity and creative ingenuity, it becomes quite real to carry out any projects, achieving excellent original results on their own.

And if there is a desire, in addition to assembling furniture on your own, you can also master the technology of applying a simple stained glass window or drawing.

The comment was sent successfully.