Wooden sun loungers: features and DIY

Being outdoors is always pleasant and enjoyable. But at the dacha, you almost inevitably have to deal with various complex matters. When tired, a short rest on a sun lounger helps out, which is not necessary to buy, because you can save money by doing the work yourself.

Description of construction

Appointment

A lounger for a summer residence (more precisely, a chaise longue) is an original armchair for a quiet rest. Possibility to adjust the height of the support and change its location. Compared to similar, seemingly, furniture that does not unfold, expandable sun loungers and sun loungers are much more practical. They began to be used for relaxing in the shade of trees in 17th century France. Despite all the difference in eras, the practicality of such products is appreciated by our contemporaries.

Usually sun loungers have a lightweight, almost weightless design. The seat is lengthened, so stretching the legs is not a problem. The back of the product is sloping. In some cases, armrests are provided. The height of the backs, like that of room chairs, is 0.4-0.45 m, and the width is 0.45-0.6 m. As practice shows, it is these proportions that allow you to comfortably recline.

Varieties

Folding wooden sun loungers can be made in various types. The oldest version looks like a chair bed. The upper block is close in appearance to the back of the chair, and the lower one resembles a medium-sized sofa. In such models, you can easily change the location of the back. Often there are options such as:

- rocking chair;

- hanging sun lounger;

- a chaise longue with an anatomically thought-out design;

- folding product.

To make it easier to move the chaise lounge, it is usually equipped with wheels. In this case, moving furniture to the right place is not difficult.

As for the anatomically thought-out designs, they faithfully reproduce the geometry of the human body. However, it will be possible to assess the real anatomy only after the start of use. When making a sun lounger with your own hands, you can make a very original design, which no one will do on an industrial scale due to unprofitability.

In some cases, a stable powerful support is abandoned. It is successfully replaced with rounded hoop-type legs. Then the chaise longue actually replaces the rocking chair. Such a product can be easily placed in any convenient place. Moving it somewhere else is also not difficult.

Thanks to the chaise longue, you can guarantee extremely comfortable conditions for unloading the spine and adjacent muscles - the reclining posture is therefore valuable for those engaged in constant work in the beds. Changing the backrest angle is very easy. A well-executed structure will decorate with its very appearance both a garden (vegetable garden, lawn) and a veranda or terrace.

When creating a structure, a variety of design approaches can be used, and wood is quite cheap.

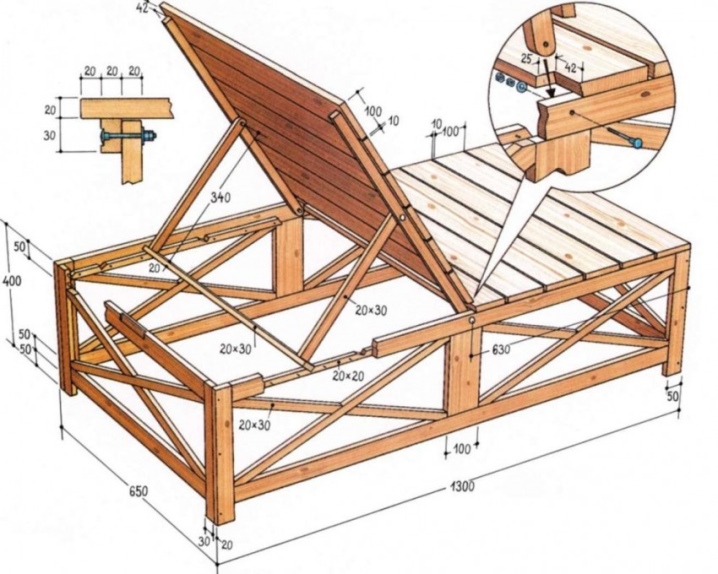

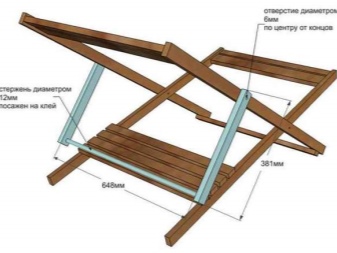

Dimensions and Drawings

When choosing a scheme for creating a wooden deck chair, you can safely ignore all the beautiful photos of the "resulting result". You should pay attention, first of all, to the elaboration and detailing of the drawings themselves. Good documentation necessarily contains a complete list of sizes for each, even a very small part. An example of such a drawing is given at the link below.

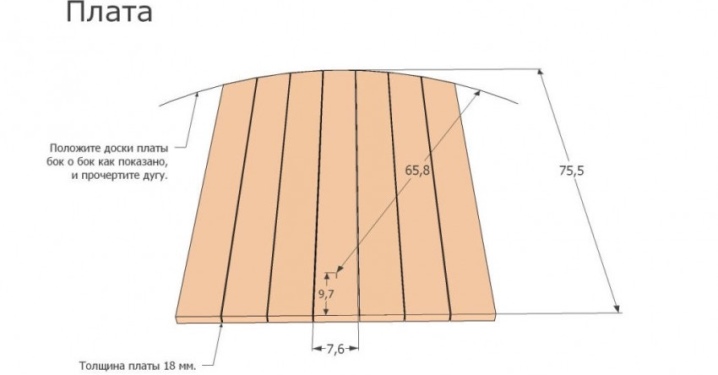

It is very important to make sure that there are drawings for each part separately (for example, such a diagram as in this photo).

When choosing dimensions, it is best not to try to reinvent the bicycle, but to build on the proportions that are used in the manufacture of factory models:

- 1.99x0.71x0.33 m;

- 1.99x0.59x0.28 m;

- 2.65x1.5 m;

- 2.19x0.7x0.47 m.

Required tools and materials

With all the positive qualities of wood, it is not very reasonable to make a chaise longue only from it. In the overwhelming majority of designs, various fabrics are additionally used to provide the necessary softness. A fabric construction with a wood frame implies preparation:

- strong fabric (denim type, canvas or tarpaulin) in the form of a piece of 2x0.5 m;

- 6 rails measuring 0.25x0.6 (in pairs, the length of the rails is 0.62, 1.1 and 1.2 m);

- 1 slats with a section of 0.02x0.02 m and a length of 0.65 m;

- 2 slats with a cross section of 0.02x0.02 m and a length of 0.5 km;

- PVA glue.

For the manufacture of the legs of a chaise longue, bars or solid wood are used at their discretion. Typical technology also implies the availability of tools such as:

- nuts and bolts of the required size;

- file;

- square;

- tape measure with 3 m tape;

- emery with minimal grains;

- electric saw;

- hand or electric drill;

- weaving devices (if you have to work with jute, rattan, willow vine).

How to make it yourself?

In general, the progress of work on the creation of a wooden deck chair is easy for everyone who is at least a little used to working with their hands. However, with a lack of experience, it is better to study not one step-by-step instruction, but several. This is the only way to bypass all the pitfalls and achieve an excellent result. But you can do it even easier: just read the article to the end.

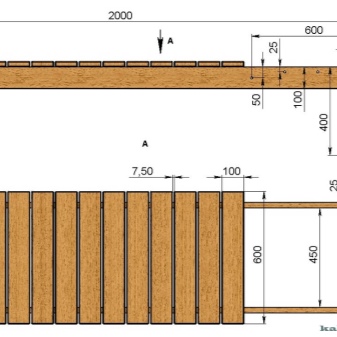

First of all, prepare the parts that will be used as a frame. Using lumber, blanks (boards) with a size of 4x0.025x0.08 m are formed. The next step is the preparation of bars with a section of 4x0.05x0.1 m. Then a pair of studs are prepared for fixing.

Important: All wooden parts are properly sanded and treated with a protective coating to prevent rotting and mildew. Before taking any step, check with the sun lounger manufacturing scheme as a whole.

To make a seat, the boards are cut into 0.6 m long pieces. The number of boards is selected individually, taking into account the gaps between them. To create a typical sun lounger with dimensions of 0.6x2 m, you can get by with 13-15 boards, the intervals between which will be 0.01 m. The joining of the boards to the frame is done with a screwdriver.

Attention: you should not rush at this moment. All segments must be mutually parallel. Even the slightest curvature of the lines should not be allowed.

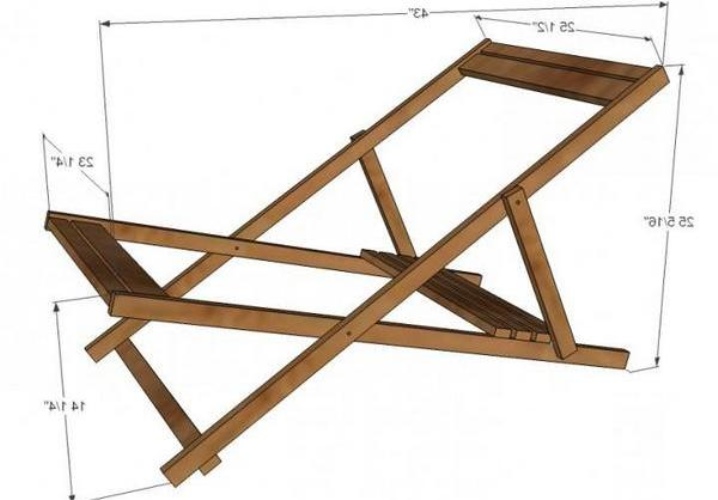

The next step is attaching the legs. Before adding them to the overall assembly, the length of the legs is trimmed so that it is exactly 0.35 m. If you wish, it is reasonable to make the chaise longue a little lower. The support bars are placed at the extreme points of the structure.

Recommendation: To save money and time, use a single support for the headboard. The backrest begins to be made with the formation of a frame. This frame must easily fit into the main structure, otherwise it will have to be adjusted.

The frame of the frame is made of 2 fragments of 0.88 m each and 3 parts of 0.039 m each. Possible gaps around the perimeter can be ignored, because they will ensure the free opening of that very back. Rails are attached to its frame. You can put them both across and along - as it is more convenient for anyone.

Self-tapping screws must be screwed in with the expectation of drowning in a layer of wood to ensure safety. From above, the slats are usually rounded off - this makes the design looks prettier. To increase the reliability of the chaise longue, the formation of through channels in the back and the main part helps. Studs are inserted into these channels and secured.

An interval of 0.2 m is made between the grooves in the main structure. To adjust the position of the backrest, a 0.6 m long bar is used. It is placed in the first or second groove of your choice. Finishing is done at your own discretion. Often they use paint, varnish or decoupage decoration technique.

But there are a few more subtleties that need to be considered. After completing the work, it is better to close all the holes with wood fillers or special plugs. For maximum comfort, castors are attached to the sun lounger. So that this can be done, the legs in front and behind are placed different in height. The hole for the axle should be slightly larger than the axle itself - then the view will be good and there will be no problems when using it.

Slats for the manufacture of structures can be made of beech, birch and oak wood. An array of other hard rocks is also sometimes used, but the result will be worse. PVA glue is needed to hold the ends of the rails more reliably. The fabric is stretched, the edges are wrapped on the crossbars and they are sheathed with a strong thread.

It is advisable to check the result after each step - it is easier to correct errors this way.

Caring for the finished sun lounger

No matter how carefully the homemade sun lounger is made, its long-term use largely depends on the correct approach:

- all textile parts must be systematically wet cleaned;

- mechanisms responsible for folding are lubricated with machine oil;

- a layer of paint or other coating regularly, as it wears out;

- it is strongly recommended to transfer a chaise longue to a heated room with the approach of cold weather.

For information on how to make a sun lounger out of wood for the garden, see the next video.

The comment was sent successfully.