Varieties of washers and their areas of use

Washers are widely used when creating various fasteners, but not every home craftsman is able to find out what it is, as well as determine the required weight and dimensional parameters of the product. The classification of products includes a division according to many characteristics - from the type of performance to the material of manufacture. To understand the difference between a fluoroplastic and metal conical washer, crown and square, roofing and toothed, other types of such hardware, a detailed story about their individual characteristics and purpose will help.

What it is?

Washer is a metal or polymer product included in multi-piece fasteners. It is needed to increase the plane of the support with which the screw or bolt contacts. Sometimes this element acts as a retainer - such washers are called locking, locking, they prevent the connection from unscrewing. They are installed in especially critical areas - where the loosening of fasteners can be dangerous.

In joints where soft surface material may be damaged, place a washer under the nut. If the part requires sealing of the joint, silicone or fluoroplastic products are used. For machine building, machine tool building, other industries, products are used from metals and alloys, including stainless, non-ferrous. The standard washer looks like a flat piece with a solid surface, there are options with a slot or notches. Also available are gear elements with hooks on the inner or outer diameter.

The designation of the washer during manufacture includes accuracy classes - A, C, as well as type 1 or type 2.

Differences from the nut

The washer, although it is an integral component of the screw connection along with the nut, has significant differences. The main one is the absence of threads. At the nut, it provides a secure connection with bolts, rods, screws. The washer does not carry a fastening function; rather, it acts as a gasket or an insulating component.

There are differences in the form of products. The nuts have external edges to facilitate installation. The key clings to them, allowing you to turn and fix or unscrew the product. The outer surface of the washer is most often smooth, in some cases toothed. The materials of manufacture, and the strength characteristics, and even the thickness, also differ.

Primary requirements

Washers are standardized products that must meet specific requirements. Among them is the absence of visible defects. Burrs and sharp edges, cracks and tears are not allowed on the surfaces of products, traces of rust are also considered unacceptable. According to the accuracy class, the products can belong to class A or C, have a flat round, oblique square or serrated shape.

Manufacturing can be carried out with or without coatings. Heat treatment of products in production is carried out on an individual basis. For steel washers of accuracy class A, hardness values are set at 140HV, for C - at least 100HV.

Species overview

Washers are used for fastening polycarbonate and roofing structures, for a wire tray and fixing in a bolted joint and complete with screws, which allow to reliably isolate or fix the parts more firmly.There are highly specialized types of such products - for door hinges, electrical engineering, oil-resistant for machines and mechanisms.

Most often, for a threaded bolt, washers are made of stainless steel, galvanized, from non-ferrous alloys. They are also non-metallic, made of silicone, textolite. All types of washers can be divided into groups, according to their shape, size and other characteristics. Some of them are worth considering in more detail.

- Insulating. This category of products must have dielectric properties, since it is used as a spacer between materials with high conductivity. Most often, a textolite washer is used, which has a fairly long service life.

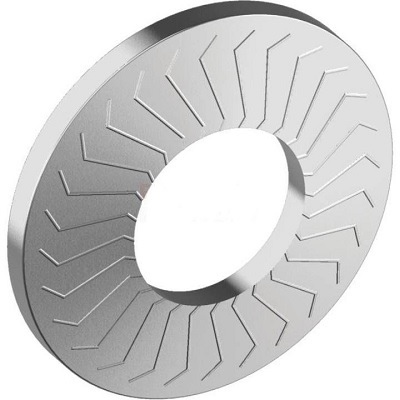

- Contact. This type of washer has radial notches or scars on the working surface. Products are made of springy steel. This combination makes it possible to make the contact at the junction as tight as possible.

- Sealing. Products of this type are widely used in the automotive industry, as well as in the creation of hydraulic systems and equipment. When installed between the fastening elements, they act as a sealing and sealing element.

For the manufacture of such washers, plastic materials are used, including soft metals - copper or corrosion-resistant alloys.

- Oblique. Washers of this type have a wedge-shaped cross-section. They are necessary to connect I-beams, channels and other types of rolled metal, in which it is required to compensate for the slope of the planes.

- Conical and spherical. Specially shaped washers designed to reduce the pressure on the support plane. They have shock-absorbing properties that compensate for distortions and backlash that occur at the junction. Initially, they were created for fastening workpieces during machining, the conical or spherical shape is selected depending on the features of the mounting plane.

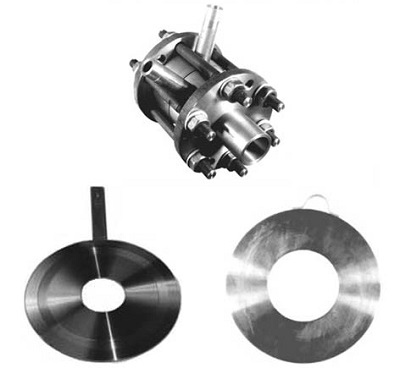

- Flowmeter. A pipe structure element in the form of a flat ring with a hole in the center. The product is installed between the flanges and acts as a diaphragm. The hole has 45-degree leading edges at the edges.

- Centering. The structural elements of loudspeaker systems are known under this name. The washer is part of the speakers, provides linear movement of their diffusers.

- Breakup. Specialized washers for use in the automotive industry.

- Spacer. A variety of fasteners made of carbon steel. The washer compensates for the pressure on the bearing surface, preventing damage to it.

- Reflective oil. Products of this type are used to protect the bearing from flooding with lubricants. The part belongs to the sealing elements, has additional gaps on the annular surface.

- Remote. A special type of elements installed in furniture structures. In addition to the flat ring, it has a tubular part in the form of a sleeve. Such elements are in demand in lifting mechanisms.

- Quick release or support. It has an original surface geometry, provides easy installation without additional devices. Removing the washer is also easy enough.

- Throttle. A special category of products installed in gas pipelines, steam pipelines, heating systems to increase the resistance of the medium. Their design can be disk or chamber, the cross-section is constant or variable. Such washers are responsible for adjusting the level of resistance in the system, help control the intensity and uniformity of the flow of heat carriers or other media.

There are also basic varieties, the most widespread in the formation of screw connections. These types of washers are used in various fields of activity, usually they do not have a narrow specialization.

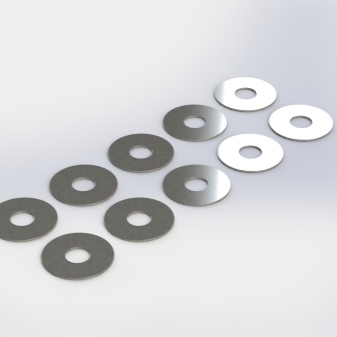

Flat

The most common type of washer.Products can have a round or square shape, most often they are made of metal, but they can be fluoroplastic, as well as from other types of plastic. The size range of flat washers is the widest; they can be reinforced, reduced or increased.

Square options are most often used when assembling wood structures with a similar section. Reinforced flat washers are thicker. This is a necessary condition for reducing the deformation effect on the plane of the part.

Reduced

Belongs to the category of flat washers. They differ in the area of the contact surface. It is smaller than the standard options.

Enlarged

Large square or round flat washers of this type are used for assembly work. The increased contact surface area allows for a closer fit of the elements.

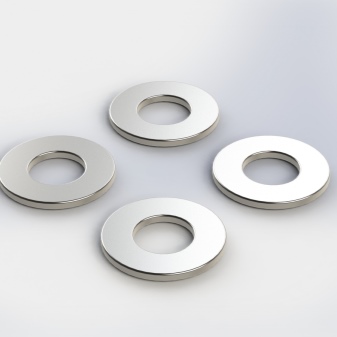

Spring loaded

Also, this washer can be called split or grover. Usually it is in the form of a 1-turn spring, in which there is a gap directed against the rotation stroke. When installing spring washers, it is possible to obtain a threaded connection that provides a maximum tightness without the risk of loosening. Fixation takes place with a special edge on the product. It crashes into the plane of the support, wedging in it.

The double-turn spring washer is used in the installation of railway tracks. Single-turn has a wider purpose. For its manufacture, they choose not rods or metal in sheets, but only wire of certain grades of steel. Wave spring washers are made of zinc plated or oxidized steel.

Rectangular

This type of flat metal products is similar to square and rounded, but has a different section. The main area of application is the assembly of solid wood structures.

Growers

This name hides all the same spring washers made in accordance with GOST 6402. The ends of such a fixing hardware are located in different planes.

Stop

The locking washer is intended for locking the threaded connection. Such products have a serrated inner or outer surface. In the process of tightening the fastener, the self-locking part is deformed, acting as wedge clamps. The lock washer, fitted with a foot or toe, prevents the bolt from loosening. During installation, its protruding element is bent towards the edges of the nut.

The lock washers also include castellated washers with a multi-footed design. They are made from steel and softer metals. The so-called "sprocket" is also a lock washer, has external teeth. Locking varieties are used to prevent axial displacement.

These washers are suitable for installation in locations that do not require pre-tightening.

Anti-vibration

A special category of washers is vibration damping. It is intended for installation in metal frames, in the places of their contact with the base, to prevent the transmission of structure-borne noise at the attachment points. Such products are made from synthetic elastomers, most often rubber.

Materials and coatings

Washers for various purposes are most often made of metal, they are assigned a strength class corresponding to the type of performance. For example, corrosion-resistant steel 20X13 or non-ferrous alloys are used for operation in aggressive environments. Bronze, aluminum, brass, copper washer will do just fine. Stainless steel options are also popular, and high-strength products are obtained by adding alloying components - most often chromium (40X).

Other requirements have to be taken into account as well. Washers of class 4.8 or 5.8 are not chrome plated, they are made of steel 10 or 20. If higher performance is needed, an unhardened composition 20G2R is taken.

The application of a protective layer has a positive effect on the characteristics of the product. The coverage can be like this.

- Galvanized. The outer protective layer is applied by hot or galvanized galvanizing.

- Cadmatized. It is applied to copper washers in fresh and salt water to protect against aggressive media.

- Multilayer in a combination of copper, chromium and nickel. Applied by electroplating. The product receives protection from rapid wear, the effects of acids and alkalis.

Nylon, silicone, fluoroplastic, textolite washers are used for acoustic systems and decorative structures, other mounting connections in electrical engineering or other fields. They have sufficient elasticity and tightness of contact, have a long service life.

Dimensions and weight

The dimensional parameters of the washers are determined depending on the standardization system used - according to DIN or GOST, the difference is insignificant, but the marking may differ. Much more important is the width of the fields, which determines the difference in the outer and inner diameters. The mass largely depends on the material from which the product is made, for example, a large steel washer will definitely be more massive than a silicone or fluoroplastic. The size is determined by the inner working diameter.

The most popular options should be considered in more detail.

- Flat to DIN 125. The size ranges from M3 to M24 with a weight of 0.12-32.3 g. In stainless steel, the inner diameter is presented in the M5.3-M12 options. Weight from 0.5 to 6.27 g.

- Spring or grovers according to DIN 127. They are produced in the size range M4-M16 with a weight of 0.38-8.93 g. Stainless versions are heavier, weighing from 0.5 g.

- With internal teeth according to DIN 6798 J. They are produced in size M3.2 with a product weight of 2.33 g.

- Body DIN 9021. Enlarged ones (with a wide platform) have dimensions M3-M20 and a weight of 0.34-76.92 g. They are also found in stainless steel. The most common size is M10.5 with a weight of 15 g.

- With external teeth DIN 6798 A. Available in size M8.2 and weighing 2.33 g for stainless steel.

Flat steel and galvanized washers are standardized in Russia in accordance with GOST 11371-78 or GOST 18123-82. Body and enlarged ones must comply with GOST 6958-78. Growers are produced with an inner diameter from 4 to 48 mm, weight from 0.12 to 14.5 g. The standard for them is GOST 6402-70.

Applications

Washers are in demand in various fields of activity. They are used in the assembly of furniture structures, the connection of building elements, the installation of pipelines and linear communications. Elastic silicone options are in demand in everyday life. In industrial production, the main areas of use of washers can be called machine building, shipbuilding, machine tool building.

The purpose of the washer is determined depending on the shape and design. For example, oblique ones are needed to compensate for the difference in angles of parts or planes; they are used to fasten I-beams. Contact ones improve the adhesion of fasteners to the surface. Retainers are necessary to prevent unscrewing of parts; they are needed in one-piece structures. To compensate for dynamic loads and vibrations in machines and mechanisms, spring washers are used.

The comment was sent successfully.