What is a Grover Washer and how do I fit it?

A spring washer is a simple and cheap way to create a joint that won't come loose by itself. While it cannot be considered universal, the washer is widely used. It is made of high-carbon steel, capable of retaining its springy (repulsive) property for many years.

What is it and what is it for?

The spring washer is needed to forcibly fix the nut screwed onto the bolt, while it is used only once - for each specific connection. This means that its use is justified only in the case of a single bolt-on installation. After dismantling, since it loses a significant part of its springy effect, it is not recommended to re-screw it even onto the same nut-bolt joint. Since bodies with ideal elasticity do not exist in nature, any body with prolonged or excessive compression partly loses its property. It is like the ball bouncing not to the level from which it fell: the vibrations of the body on the spring - Grover's washer is just a coil of such a spring - will eventually disappear. Repeatedly pulling the lock washer turns it into a regular press washer, equal in area to the point of contact of the nut with the face of the fastened part, which it holds in place.

The spring washer as a subspecies of the locking gasket was primarily used in mechanical engineering, then it spread to the production of electrics, electronics, and all kinds of automation. It is used to secure critical parts of machines, mechanisms and electrical components. For example, to prevent the supporting structures of the carriage, car body, and desktop computer system unit from loosening, this washer is used. It fixes the electrical contacts of switches, knife switches, automatic fuses, telephone terminal blocks in the automatic telephone exchange. Wherever pads with wires are suitable, where reliable contact of the power or signal line is needed, at least one spring washer is used - one such wire with a C-shaped contact, remotely resembling a simple block.

An example of use is the terminals of electric motors: significant inrush currents are forced to provide a very reliable contact, in which there will be no arcing.

History of creation

The puck is named after the mechanical inventor John Grover. The beginning of widespread distribution - the end of the 19th century, during a period of active, explosive growth in demand for mechanisms that gradually replaced manual labor. It appeared as a response to the shortcomings of joints, where only pressing washers were used.

Initially, design engineers tried to use conventional springs in places where it was necessary to securely tighten the nuts on the bolts, the diameter of the thread resembling the current sizes of bolts M12, M14, M16 or M20. But due to the presence of bolts of a noticeably longer structure, these were heavier, which was an inconvenience. The spring as a split component can replace the spring washer where minimizing the weight, for example, of a sprung carriage or wheelbarrow, is not so important. However, such "overproduction" invariably turns into tangible expenditures on the production of machines and products, increases their cost, so there is no need for extra turns. The purpose of the lock washer is to hold the nut in place by cutting one sharp (raised) end into it, the other into the pressing washer, which is in contact with one of the parts to be fastened. The resulting clutch prevents the nut from screwing back, as it is directed against its possible unscrewing.

The riveted joint was considered an alternative to the grover elements. Although the rivet holds the parts no worse than a bolt with a nut and a lock washer, maintaining a riveted joint, replacing loose rivets is not an easy measure. Lack of rivets - when riveting, all its details change. When opening a connection based on a bolt and nut with a lock washer, only the washer itself must be replaced: a carefully disassembled, undamaged connection can be screwed back without any negative consequences for the entire structure at this point. The number of defective riveted joints is noticeably higher than bolted ones that used a spring washer: any of the defective parts can be replaced while the rest are preserved. After extraction, the rivet is completely discarded.

The advantage of the bolted connection is that after careful extraction and cutting of the rivet using a press washer of a larger area, the resulting ragged hole is completely closed, and the appearance of the structure will not be affected.

Views

In order to finally understand whether a grower washer is suitable for your situation, it is useful for the craftsman to find out how this product can be replaced. Alternative options will allow you to fix the nut relative to the bolt as well as a grower.

-

Self-locking nuts have a plastic insert to reduce the impact of shock and vibration. But due to the relative complexity - in comparison with the grover washer - the self-locking nut is noticeably more expensive, since in addition to steel of a certain shape, other, less solid and more elastic materials are also used.

-

The poppet is one of the standard options for replacing the grower. A more reliable and cheaper type of washer. Its closest analogue is conical.

-

Crown nut - used to create conditionssuitable for installing the cotter pin through a separate hole. Due to the stepped construction, it is recognized as one of the most reliable methods.

- The serrated flange is suitable for a groove connection. From the side it seems that the steps on both sides enter each other - due to their "helical" location. The reliability of the connection and the prevention of loosening the nut is not inferior to the grower.

-

Locking washer features repetitive spikesprotruding at a slight angle - relative to the plane of the main surface of the product. These teeth also press into the nut, preventing it from loosening.

- Burr washer allows one to be left within the workpiece, thanks to this, the remaining ones go around the turns. It is presented in several varieties, specific to a particular situation.

-

Wire clips differ in extremely low cost and the simplest production technology.

- By bending an ordinary press washer, they get the simplest wavy - for example, for nuts M6, M8, M10. But the truly bouncy wave washer is made of a thinner strip of steel than a conventional grover, bent around the circumference. The cut, like a grover washer, is absent in the wave.

The purpose of the product is to eliminate the longitudinal movement of the rotor when the motor is running.

For example, Belleville washers are used as a kind of shock absorbers, damping shock and vibration on bolted mountings. The main part of the impact falls on them - the nut and bolt will remain. Manufactured from high-carbon spring steel. Compliant with GOST No. 3057 (edition of 1990). The tension in the bolted joint when using Belleville washers is stabilized, sharp moments of force are eliminated, and in a narrow space they are used as a coil spring (one turn). The purpose of the washer is to take over the temperature fluctuations "heat-cold", which normally lead to damage to the nut and bolt, used without any washers. Some manufacturers, in an effort to save more on production, assembly of a whole range of household goods, deliberately do not include spring washers in the package. The consumer, seeing that they are not there, buys in addition "growers" on his own, before finally assembling a thing or object in which bolted connections are used.

Simple

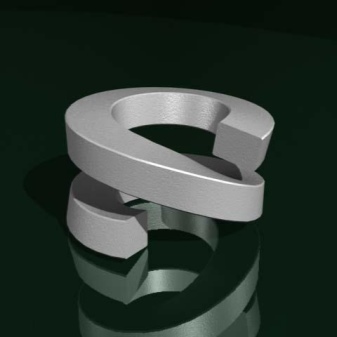

A simple grover part is a spring coil. Theoretically, it seems that in order to solve the issue with grover washers, it is enough to take a grinder with a thin disc, or another saw, for example, a thin disc on a saw machine and, fixing, for example, a spring from a clamshell in a vice, saw it along - on the one hand, carefully while controlling the sawing in order to avoid sawing from the diametrically opposite side. Washers of round cross-section, obtained from such a "wire" (a spring is in fact a wire made of high-carbon steel, which has good elasticity when compressed from the ends), can indeed solve the problem of tightening the connection.

By the way, plain washers are smooth, burr-free spring coils. The cross cuts - the ends of the sawn springy coil-ring - are offset, they do not "aim" exactly at each other. If they really coincided, such a detail would be useless: it would not fix the nut at the moment of tightening, which means that such a steel gasket has no reason to be called a grover.

The cut of the ring is made at an angle of 70 degrees, and not conventionally perpendicular to the tangent passing through the point (line, inner edges) of the cut.

Complex

These components are called complex, first of all, because this element was developed for the complicated operating conditions of structures and mechanisms, such as: rotational movements of mechanisms. In particular, an aggressive manner of driving cars with frequent overloads, manipulation of the operator on special equipment, accompanied by special working conditions, for example, a truck crane when lifting and transferring stacks by weight at a considerable height, and so on.

The second factor is two-turn execution. These are two consecutive turns with the same cross-section as that of simple washers. In other words, a "double" washer is a piece of a spring, the coils of which were deliberately "forgotten" to divide, cut along the same line. The section of the coil at any of its points is not round, like in ordinary springs, but rectangular, less often trapezoidal profiled washers are found, in which the lower edge of the spring coil, which they are, is slightly longer than the upper one, while the side edges are directed upwards, slightly beveled. The prototype of two-turn washers are spring sections in several turns. The field of application is not only as a grover gasket, but also as full-fledged springs in extremely narrow spaces. The elasticity, the resistance of two turns in comparison with one (single) also increases markedly.

The grover part does not possess the property inherent in its “non-spring” competitors: it cannot be combined as a whole with a nut, bolt, or pressing washer. It is, as a rule, an independent and disposable element that can be easily changed during the subsequent reassembly of bolted connections.

Material

According to GOST 6402 (as amended from 1970), the material for the grover parts is steel 65-G. It is a type of high carbon steel suitable for spring springs for ground vehicles and a variety of construction equipment used in large-scale construction. An exception to this rule is the use of bronze alloys.

However, bronze, in contrast to "spring" steel, almost does not have that elasticity, and it is rarely used in serious structures.

How to install correctly?

There is a set of rules for installing bolted connections using spring washers. They all boil down to the following.

- Do not use steel lock washers with bronze, aluminum nuts. Burrs, differences in the plane of the grover section leave furrows on them when tightening the nuts from non-ferrous metal, which can lead to nut breakage.

- The grover connection cannot be dragged. Overtightening a nut of any size in any case makes the part flat, turning it into a regular gasket, almost devoid of springing effect.

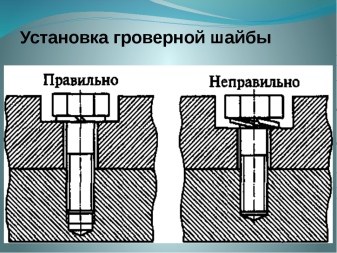

- The grover washer must not be placed under the pressing washer. The second should be farther from the nut and / or from the head of the bolt than the first. That is, the bolted connection is completed in the following sequence: the bolt head, the spring washer, the press washer, the workpieces being fastened, the press washer, the spring, the nut, not otherwise. More specifically, the washers are installed in a mirror-like sequence on either side of the parts to be fastened.

- It is unacceptable to clamp the spring washer between two pressing. If the bolt is long, and the thread is not cut along its entire length, but there is an unoccupied gap between the nut and the parts to be fastened, then one or more press washers are first laid, then one or more grover washers, and finally the nut is screwed on. That is, the press and grover washers should not alternate either randomly or cyclically. The package resembles the correct loading of the barbell bar. The method of "mirroring" the washers is valid in this case as well.

Bronze spring washers with steel nuts and bolts will have no effect: neither aluminum alloy nor bronze will give the expected effect. Use only high quality steel fasteners, not counterfeit ones.

The comment was sent successfully.