DIY options for making a chain-link mesh

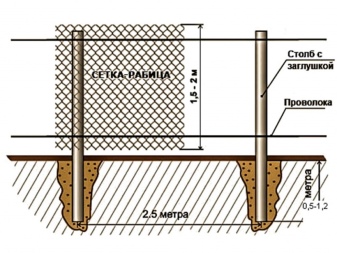

Rabitz used for many purposes. Most often it is used when erecting a fence in summer cottages. Making a grid with your own hands is quite simple. You must first master some technical features. You will also need basic locksmith skills.

How to make a manual machine?

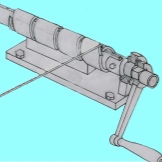

For production you can use homemade device... The machine can be like machineand semiautomatic device.

The device is suitable for weaving mesh with any mesh size. The most popular sizes are 8x8 cm and 4.5x4.5 cm.

The machine consists of the following parts:

- a drum that feeds the wire;

- bent channel, section;

- metal rollers;

- bending machine.

A simple bucket can play the role of a drum. A wide board is used as a basis. A bucket is installed on top, bottom up. To prevent the bucket from falling during the weaving process, fix it with any weight.

A wire must be wound on such a homemade mechanism. Then it will be fed to a channel with three metal rollers. For their high-quality rotation, it is worth using bolts as fasteners. Usually they are supplemented with restrictive washers of a small size of about 1 mm.

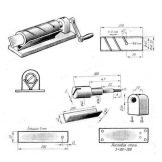

The bending machine is also self-made. It is permissible to use a steel pipe of a suitable size, but always with thick walls.

A spiral groove should be made in it at an angle of 45 ° to the axis... The size should be about 4-5 mm. At the end of the groove, about 5 cm before the end of the pipe, you need to make a round hole. All this is necessary in order to install a carbide knife (usually steel).

The pipe is connected to the angle using a welding machine. Later place the structure on a secure base and fix it... It is important not to close the groove during welding.

The knife is fastened with a screw or hairpin. Support adjustment is possible with a washer. It is necessary to make the entire weaving machine step by step and extremely carefully. For simplicity, you need drawings with dimensions and markings.

Additionally, you can make a lever. It will simplify the process of twisting the wire. It is attached directly to the visible part of the knife. This addition is especially important if you plan to make a large amount of mesh.

Mesh making

First, you should spend small preparatory actions. The braiding wire is lubricated with oil, you can use already used material.

Even this process can be slightly automated and simplified at home. For this, a small mechanism is constructed from a box with a through hole, with a diameter slightly larger than the wire cross-section.

Oil is poured inside, and the raw material is passed through this device and lubricated in the process.

The manufacturing process itself is quite simple. The weaving sequence usually looks like this.

- The end of the wire is crocheted. The fold should be about half the width of the mandrel knife.

- The hook is inserted into a groove in the pipe and clings to the edge of the steel tool.

- The knife must be rotated. As a result, the wire will wind, curl and move further along the groove. The output is a wavy wire. Its length is equal to the width of the future canvas. It is worth noting that the work surface must also be suitable in size.

- After reaching the required length, the wire is cut with pliers at the bending unit.

- The finished workpiece should be moved away from you by the width of the cells of the future canvas.

- Next, the process of making the next section begins. The new workpiece is screwed into the previous one by itself. It is only important to always twist the knife in one direction. Otherwise, the workpiece will be damaged.

- The process is repeated until the canvas is ready.

During the manufacturing process, it is important to monitor the quality. A well-made workpiece should lie absolutely flat on the table, without twisting into a spring.

If this is not the case, then the reason may lie in the elasticity and tension of the wire. Also, problems arise with the angle of twist of the knife along the axis.

A homemade machine allows you to make a chain-link mesh in any quantity... A standard snake 1.5 m in size will need about 2.3 m of wire. One running meter with 8x8 cm cells is made from 25 blanks. This amount of 2.5 mm wire mesh weighs about 2.5 kg.

Individual parts and canvases are easily fastened together. To make the netting easier to dock, you do not need to unscrew the outermost wire. The finished canvas can be used immediately, for example, for a fence. For a longer service life, it is recommended to paint the mesh after installation. The reliable layer is easy to apply with a brush and protects the wire from aggressive environmental influences.

We make a chain-link without a machine

It is not always possible to make a mesh weaving tool. You can make a chain-link without a machine.

This process will take more time, but the quality of the result will not be affected. The same wire or plastic can be used as a material.

In the latter case, the mesh is purely decorative in nature due to its lower strength.

It is quite easy to make any number of meshes this way. Manufacturing takes place according to the instructions:

- To begin with, you should choose a tool that will allow you to give the wire the desired bend.

- You need a working surface, the length of which will correspond to the width of the chain-link. Even a simple wooden board can be used.

- Drive nails into the work surface in a checkerboard pattern. The distance between them forms the size of the future grid cells.

- Cut the soft steel wire into equal pieces. This is a kind of weaving blanks. Quite a lot of them may be required, depending on the desired length of the chain-link.

- It is recommended to protect your hands with durable gloves.

- Take a wire blank and gently bend around the nails.

- The rods are easily interconnected by weaving. You can also simply rotate one workpiece around the second, as if twisting it.

There is another way to make the mesh yourself without a machine. You will need wire cutters to cut the pieces of wire. Used aluminum or similar raw material, which is easily deformed. You should also take wooden rulers or electrodes bent in half. The process of making a chain-link by this method is simple:

- Take a ruler or electrode and wind the wire tightly. There should be no free space between the turns. In this case, it is the width of the ruler that forms the size of the grid cells.

- It is recommended to double-check the quality of the bends.

- The finished workpiece is removed and the next one is wound. It is important to make turns in one direction, otherwise weaving will not work.

- All twisted workpieces must be stretched to the same length.

- The resulting spirals are threaded one by one using rotational movements.

- The first and last row must be additionally secured. This will avoid accidental mesh disintegration.

Making a decorative chain-link from plastic bottles with your own hands requires a little preparation... Prepare a tape or tube in advance. Blanks are easily made from bottles in just a few minutes. Usually a small size is used within 2-5 mm.Additionally, you should prepare a ruler and an alcohol lamp.

The very principle of the robot is quite similar to wire weaving. The production of a chain-link from plastic takes place in several stages:

- On the ruler, you should draw squares that will serve as guidelines.

- The edge of a ribbon or plastic tube is attached to the ruler with a clothespin.

- The workpiece is wound gradually. Each bend needs to be slightly warmed up.

- Secure the second edge. Run the entire structure over the spirit lamp again to warm it up additionally. This will fix all the loops.

- Remove the workpiece. Treat all subsequent parts of the plastic tape in the same way.

- Screw in cooled workpieces. It is recommended to secure the upper and lower parts additionally.

In the next video, you will learn how to make a netting at home.

The comment was sent successfully.