All about serpyanka

The range of protective and insulating construction devices and materials is constantly expanding. Despite this, the serpyanka is considered one of the most reliable products. Self-adhesive serpyanka has a number of advantages that allow it not to lose its relevance for a long time. Possession of the technology of its correct application, knowledge of the conditions of its operation and the rules for working with it will help to ensure effective protection of walls and various construction interfaces for a long time.

What is it and why is it needed?

In the recent past, when carrying out repairs, simple gauze impregnated with a special composition was used for reinforcement. The bandage was placed on the wall and putty was applied. Nowadays, the latest devices and materials are used that effectively protect corners and joints from cracking. Serpyanka has become such a remedy. Serpyanka is a tape that includes a mesh with fine meshes and a special adhesive layer. The area of its use is extensive, mainly in the field of construction. It is used to strengthen the elements before finishing. Its purpose is to reinforce walls, corners and various types of joints. It is often used when working with plasterboard. Perfectly preserves the integrity of plasterboard structures.

The main types of work with serpyanka:

- interior finishing works, increasing the strength and durability of the main and auxiliary, as well as structural elements;

- external strengthening of facade elements of buildings;

- restoration of partially destroyed walls.

In addition to the well-established traditional methods of use, it is convenient for strengthening corners and joints that do not have sufficient fixation, at the junctions of window and door frames with the wall, as well as on ceilings and floors.

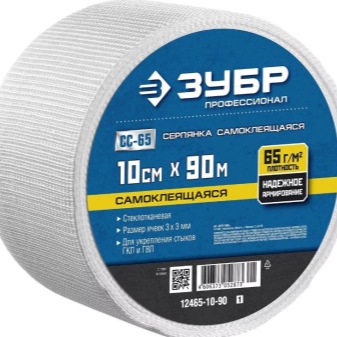

With the help of the mesh, the impact-resistant qualities of any surfaces are really increased, since it works like a screed that does not allow the wall to disperse. The purposes of application determine the specific types of products used, differing in cell sizes, the quality of the adhesive coating or its absence. Self-adhesive serpyanka is especially effective in application, when the master or amateur does not need to carry out additional types of work and buy glue. Its use is regulated by GOST.

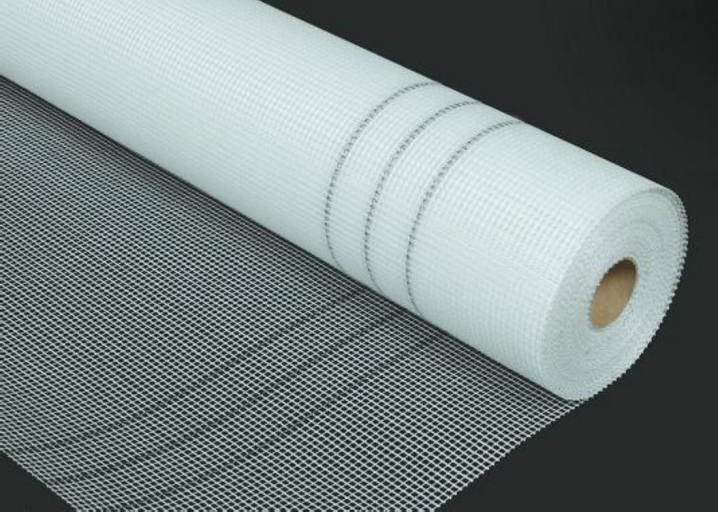

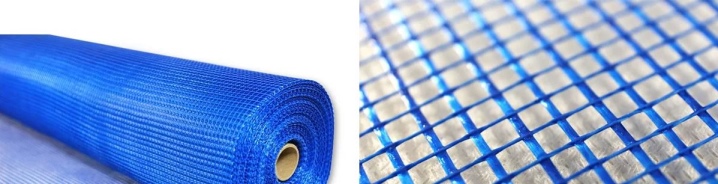

Serpyanka is made of fiberglass or synthetic materials. Sold in roll form. In practice, this is a mesh that provides convenience and ease of work, preventing the appearance of blisters on the treated surfaces. Usually, such a tape is installed on a putty drywall sheet, which increases the degree of adhesion of the elements to be joined. The mesh texture of the product is uniformly coated with a special glue, which largely makes its attachment reliable, ensuring proper quality.

Serpyanka is practical and convenient for:

- gluing seams;

- smoothing cracks;

- reinforcement of wall and ceiling elements.

Such a mesh is guaranteed to preserve the putty coating and provides a high degree of strength of the joint, preventing the appearance of defects. Serpyanka is distinguished by:

- high degree of strength;

- moisture resistance;

- high degree of adhesion;

- anti-corrosion qualities.

The product is flawless when used in rooms with significant temperature differences. Its technical parameters include:

- density level 50 g / sq. m;

- size range - 42-230 mm;

- length - 20-150 m.

For the execution of internal work, a network with a small-diameter cell is used, the size of which varies within 1-3 mm. In the course of its production, thin threads are used. Their width is significantly inferior to the width of products for outdoor use. This fabric is mainly used to reinforce seams. The mesh of products for work outside is from 5 mm in diameter. Often, such meshes are produced without applying a layer of glue. Usually these are products made of glass fiber or lavsan. The first type is the most used in all types of construction procedures. Seam sealing is its main purpose.

The second type is less popular and looks more like a painting bandage. It is used to strengthen the points of convergence of window and door frames. Lavsan is thin and therefore hardly noticeable. Such a net is planted on a special glue that should not contain a water component. The pluses of Serpyanka include:

- a high degree of resistance to environmental (humidity, sudden temperature changes) and other mechanical influences;

- good shockproof qualities of the texture;

- increased service life of the processed building element;

- the effectiveness of protection against the emergence of new and increase in old cracks;

- simplicity and versatility;

- successful resistance to different types of loads (shrinkage, vibration, shear);

- high level of resistance to aggressive environments;

- the possibility of gluing on areas of significant area.

Disadvantages (for fabric versions of serpyanka): low degree of strength, selection of a special composition of the putty. The shelf life of the self-adhesive serpyanka is calculated in three years; in the future, the manufacturer cannot give a guarantee due to a decrease in the effectiveness of the glue.

Species overview

Self-adhesive construction mesh is available in different materials. Hence its classification follows.

Glass cloth

The structure of this type of net is fragile, since it is made from a thin glass thread. The material passes through a special unit (extruder), resulting in a thin, quickly solidifying thread. Then the threads are intertwined. The quality of the brittleness of the material does not allow reinforcing the inner corners with such a mesh, but such a product is quite suitable for walls and on the ceiling. The advantage of the material is its high degree of elasticity, which greatly simplifies the work. The smallest roll size in width is 4.2 cm, and the largest is 15 cm. The length of the network reaches 90 m. For drywall and concrete slabs, almost any type of serpyanka is used (versatility). But the main thing here is to choose its thickness.

If the mesh size of the mesh made of fiberglass is 1 mm (it looks like gauze), then it can be used when laying tiles on drywall sheets. You can protect the corners with a special fiberglass mesh, which is called "corner protection". This group of meshes is suitable for both reinforcement and reinforcement of corner joints when putting putty on the facades of buildings.

Lavsanovaya

Sold in rolls 5-100 cm wide. The maximum length is 100 m. The weight of such a roll is approximately 1.3 kg. The product is characterized by high strength characteristics, and therefore is used to strengthen thick layers of plaster. In construction, two types of lavsan and fiberglass nets are used:

- narrow (35-50 mm wide);

- wide (50-250 mm wide).

Polypropylene

This type of net is also called a bandage, since it is super thin. Ideal for hardening finishing layers when the plastering depth is not more than 1 mm... The lightness of the product makes it possible to use it without preliminary filling of the base. Its density is 15 g / m2. The greatest width of the tape is 12 cm, and the length is up to 100 m.The weight of the roll is no more than 102 g.

Nuances of choice

Domestic producers of Serpyanka provide a large part of the Russian market, which makes it possible for the buyer to fairly focus on the popularity of the company and the stability of a large manufacturer. The main selection criterion is the price of the product. It is impractical to purchase a cheap mesh. Market prices for a product (no adhesive) start at about $ 1 per item. With glue application, the price of the roll increases slightly.

The surface of the product must be treated with a polyacrylic dispersion that successfully resists aggressive putty elements and maintains the integrity of the mesh... However, this mesh will not be the cheapest on the market. In the buying process, pay attention to the integrity of the mesh. If it delaminates, then it's not your choice. Such a defect indicates a marriage and low quality of the product. It is worth checking the condition of the glue coating of the network, it happens that it is susceptible to drying out. In other words, the packaging of goods in rolls must be guaranteed tight.

Other criteria for the selection of products are based on their intended use and are reduced to their type, material of manufacture, mesh sizes and width (typical width - 45, 50, 100 mm). Sometimes nets are used for fabrics to increase the stiffness of the fabric backing. It is important here that the width of the mesh is the same as the width of the fabric. Generally, a wide network is suitable.

How to use it correctly?

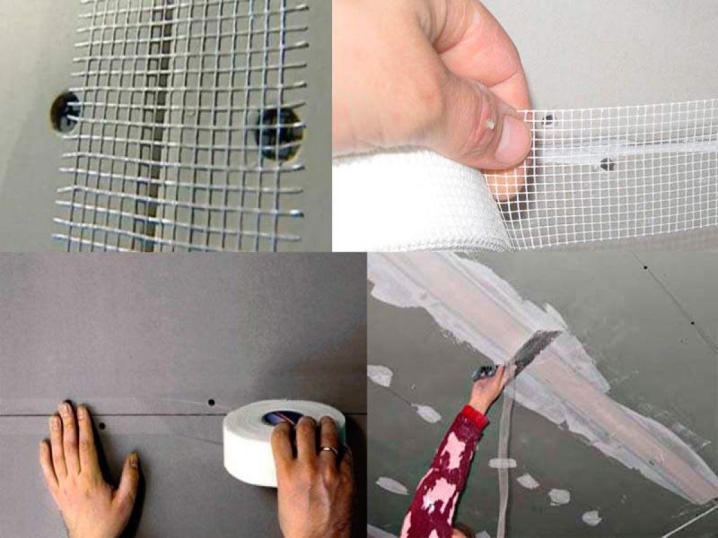

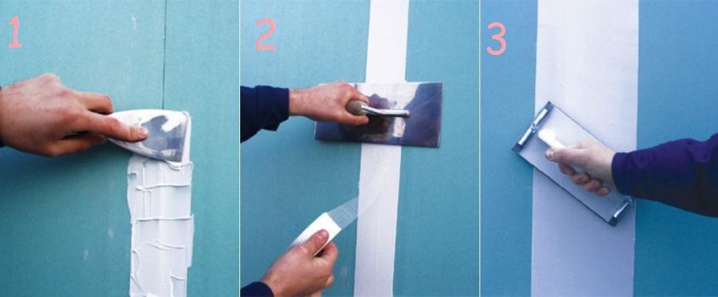

With the advent of Serpyanka, construction technologies have become noticeably more rational and simpler. Time spent on renovation of premises decreased by an order of magnitude. Nevertheless, one must understand that the repair results will be good only when all its elements are used correctly. This also applies to serpyanka. There are two well-known techniques for working with the product:

- the tape is deepened in a fresh coating with putty, on top of which another layer is applied;

- tape ("self-adhesive") is attached to the plastered surface, after which another layer of coating is applied.

The following inventory is used to work with the network:

- putty material;

- knife;

- buckets for preparing the finishing mixture;

- putty knife;

- reinforcing network.

Before gluing the serpyanka to the wall, joints or when gluing corners, it is important to carefully level the surface with a primer, tidy up the texture, and eliminate defects. This step is carried out regardless of whether you are gluing the mesh to drywall, concrete wall, ceiling, floor, or reinforcing a small corner.

The correct use of the mesh presupposes the mandatory observance of a number of nuances that effectively affect, for example, the processing of seams with your own hands and the production of other types of work. Environmental parameters and some technological features are relevant here. For example, during the production of work and during the next 2 days, the temperature in the room should be about +20 degrees Celsius. Drafts are not allowed.

The base of the product is thoroughly cleaned of dirt and dust. Drywall is cleaned with a sponge soaked in water (the addition of detergents is allowed), and concrete - with a special brush. After that, the reliability of the fasteners is checked - self-tapping screws and screws must be installed without flaws. After cleaning and inspection, the base is primed with acrylic, alkyd or acidic compounds. Then putty is applied, the main work is carried out:

- we cut off the desired piece of mesh without twisting and unraveling the threads;

- press the product into a still wet putty;

- cover with a finishing layer of plaster;

- within 12 days in a closed room we dry.

In the course of work, the penetration of dust under the network is excluded, since air remains with dust under the mesh, which prevents high-quality adhesion, as a result of which cracks may appear. The remains of the product must be sealed hermetically. A few words about the choice of types of primer. Several types of it are used: acrylic, alkyd, acid. The first type guarantees excellent adhesion, has a thick consistency and is usually available with a hardener.

Alkyd primer is thinner in terms of its parameters, and its main purpose is to fill the gaps between layers. The disadvantage of this type is the significant expense. The third type of primer is expensive. Its advantages: high degree of density, efficient collection of excess moisture. After priming, we carry out the operation of mixing the composition to strengthen the seams.The putty mixture is placed in warm water and stirred to a creamy consistency.

Beware of using PVA glue when installing the mesh. For these works, it is not suitable (especially for paper and lavsan serpyanka), since it is produced on a water base. Contact between water and metal structural elements affects the color of the putty, through which brown spots appear. Air should not be allowed to penetrate between the mesh and the filler, resulting in cracks. When cutting the tape, it is important to control its integrity. If the threads come out in any place of the product, then they should be removed. Such threads can damage the layer of material applied to the wall.

And a few more tips from experts.

- It happens that the adhesive backing of the tape is not enough for a strong adhesion. For this reason, before using the product, it is recommended to additionally cover it with glue.

- Plastering the network helps to smooth out the deficiencies of the adhesive.

- After applying the plaster, the mesh should be strongly pressed into the wall with a spatula - this contributes to an even and high-quality adhesion. The service time of the processed joint directly depends on the strength of the mesh embedding.

- Do not try to make the plaster layer thicker, as this may compromise the surface quality. At the same time, over time, its surplus can fall off under the influence of its own weight.

- The optimum finishing thickness is 70 mm for walls, 30 mm for ceilings.

- It is necessary to use "self-adhesive" carefully, trying to carefully glue it the first time. Since when it is removed, re-sticking will not work - the adhesive composition loses its qualities.

- Plasterboard sheets should be attached to the frame in the most secure way or glued. In case of poor-quality fastening, delamination may occur, vibration of the sheets will cause cracking of the seams.

- When gluing seams, when a narrow tape is used, it can move, forming a tuberosity. Then the tape is cut into small pieces, and each next piece is overlapped (10-15 mm) on the previous one. It will become more convenient to work without marriage.

- If there is a need to strengthen the "non-native" seams at the ends, then some preparation is required here. We cut off the edges on both sides to increase the seam area, which contributes to a better attachment of the putty to the surface. These sections must be primed.

It should be borne in mind that some "master craftsmen" often save material. As a result, the beautiful and seemingly successful walls crack and begin to crumble in a couple of years. The guarantee of the longevity of the interiors is the high-quality use of serpyanka.

For information on how to use the serpyanka correctly, see the next video.

The comment was sent successfully.