Features of basalt mesh and its use

Many building structures require additional reinforcement - strengthening of walls and masonry. Basalt mesh is often used for this purpose. Its features make it possible to improve the object's resistance to the effects of various external factors and to extend the overall service life.

What is it and why is it needed?

The widespread use of basalt mesh is directly related to the popularity of materials such as foam blocks and aerated concrete. They can be used to build warm and durable buildings, they are easy to install due to their porous structure, and they also have an attractive cost. However, when erecting an object from such blocks, it is imperative to carry out intermediate reinforcement, therefore, one cannot do without a masonry mesh. A building without additional reinforcement will turn out to be unreliable, even if the building is located in an area where no seismic activity has been noticed. This is due to the peculiarities of the materials themselves and construction.

After construction, any house or industrial facility shrinks - drying out, soil stabilization and other processes occur, and they act unevenly. Reinforcement mesh helps prevent voids, block cracks and other imperfections that can lead to failure.

Some builders believe that modern materials have a sufficient safety margin, so there is no need to strengthen structures. However, if you look at the regulatory documents - SNiPs, you can see that the project for the construction of buildings from foam concrete or aerated concrete should provide for the use of a reinforcing mesh.

There are different types of such products - metal, plastic and basalt. Previously, steel meshes were most often used in construction work. Modern technologies have made it possible to simplify the production of basalt rebar, so it began to rapidly gain popularity. This is not surprising, since a mesh made of such a material has a number of advantages.

- Low rates of thermal conductivity. Basalt reinforcement, unlike metal, does not form cold bridges.

- Resistance to mechanical stress - stretching, bending, tearing. This is an important quality for a reinforcing material.

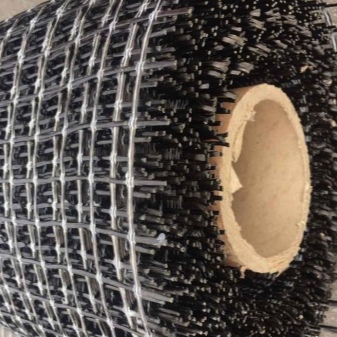

- Ease. The net does not weigh down the structure being erected, it can be quickly assembled, conveniently stored and transported in rolls.

- Resistant to alkalis and other componentsthat are used in the manufacture of concrete blocks.

- Ability to withstand temperature fluctuations.

And also basalt mesh is more durable than metal, since it does not corrode, and its cost is more profitable due to modern technologies that allow this material to be produced on an industrial scale.

How is the mesh made?

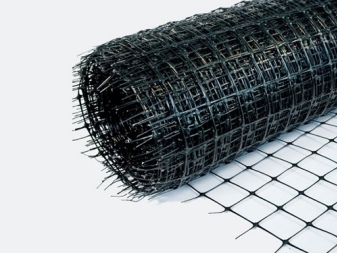

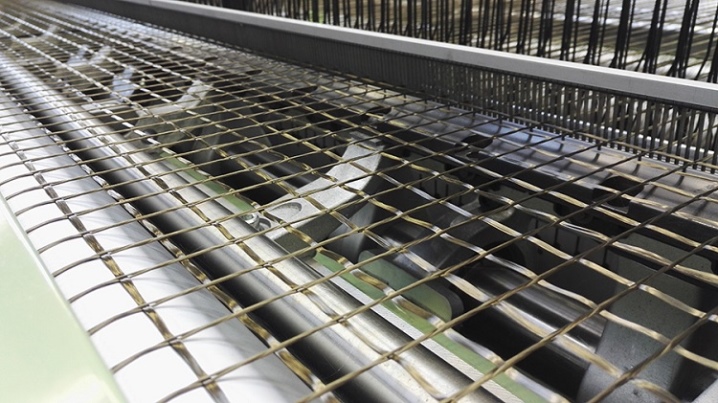

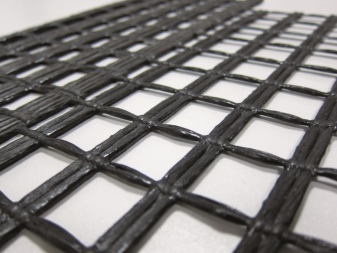

Basalt is the raw material for the manufacture of reinforcing products. It is a volcanic rock, a completely natural component. By melting at high temperature and extrusion (drawing), basalt fibers resembling filaments are obtained. Then, on a special machine, they are assembled into bundles that meet the requirements of GOST in terms of tensile strength and other characteristics. The workpieces are laid perpendicular to each other, the knots are stitched with a wear-resistant thread.

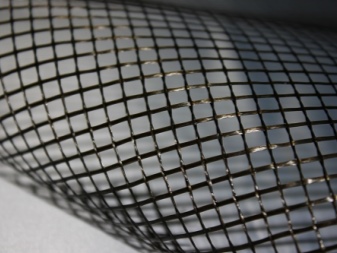

The next stage of production is impregnation with a special compound. It imparts resistance to various chemically active substances: alkalis, salts, concrete additives. Acrylates or other compounds with similar properties can be used as impregnation. It should be borne in mind that the finished fiberglass mesh and basalt mesh are very similar in appearance, they are difficult to distinguish. This is used by unscrupulous manufacturers who pass off one product for another.

To understand what the canvas is made of, you need to slightly fluff the edges of the mesh: green fibers will be visible for basalt, and white for glass.

Varieties

Reinforcing mesh is often used to reinforce brick or gas block masonry, for floor screed and other construction needs. Basalt fibers are the best option in terms of performance and price. And in some cases, using other materials is impractical. For example, metal meshes are not suitable for reinforcing aerated concrete structures, since they will quickly become unusable from contact with the substances from which the blocks are made. Basalt bed is actively used during road works. All reinforcement meshes can be divided into several types.

Construction

It is used in the construction of various objects - industrial and private. Suitable for reinforcing load-bearing structures in multi-storey buildings that have to withstand high loads. This mesh is used to strengthen brick buildings and concrete block houses. A big plus is that the reinforcing material does not make the structure heavier, so there is no need to provide for a more powerful foundation and additional supports in the project.

Road

The road, also known as basalt geogrid, is used for the construction or repair of roads for various purposes. Increases the service life of the coating, as it helps to distribute the load evenly over the entire surface, which allows you to avoid subsidence of individual areas, the appearance of cracks and other defects.

Plastering

It is used to strengthen wall surfaces. Suitable for indoor and outdoor plastering of walls. Provides good adhesion of finishing materials, avoids unevenness and cracks.

And also with the help of this mesh, the insulating winding is reinforced during the laying of pipelines.

Dimensions (edit)

Products differ in the thickness of the rods and the shape of the cells. At the same time, the range of options on the market is quite wide, therefore, when choosing the optimal size, it is worth considering the purpose of the mesh. The smaller the dimensions of the cell, the stronger the web. The most popular sizes are 25x25 mm, 50x50 mm, but you can also find 150x150 mm or 5x5 mm. The thickness of one bar varies between 2-4 mm.

The mesh is produced in rolls, the thickness of the entire web is usually a multiple of the parameters of building materials - brick or foam block. Wherein the product is easy to cut with ordinary scissors, so you can make strips of any size if required.

Applications

Basalt products are durable, resistant to various factors and at the same time affordable. It is not surprising that they are used for the construction of industrial and civil facilities, as well as in private households. With the help of nets, they strengthen:

- structures made of expanded clay, aerated blocks, foam concrete;

- large brick structures;

- beams, belts, stabilizing lintels;

- floor coverings and walls;

- dirt roads and asphalt.

The reinforcing network is chosen depending on the expected load, which is calculated at the design stage.

Styling tips

There is a certain work technology that must be followed. The nuances of installing the mesh on different materials may differ, but there are also common points. Before laying the canvas, you should cut it in accordance with the dimensions of the walls. Since the network must be overlapped, it is important to provide sufficient material in the calculations.

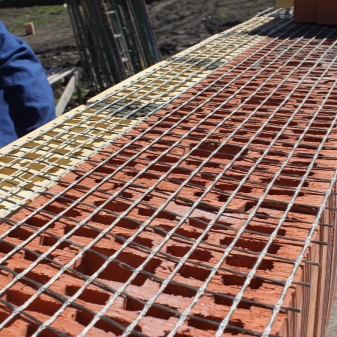

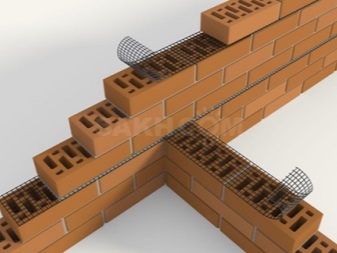

Editing alone won't work, so you'll need a partner to work with. Sections of the mesh at the joints are laid with an overlap of 3-5 cells, after which you can apply cement mortar or special glue, with the help of these compounds, bricks or concrete blocks are fixed. It is necessary to observe the fastening technology and carefully monitor that the network does not deform and does not slide out during operation, since this significantly reduces the bearing capacity.

Regardless of the type of finishing of the building, it is imperative to reinforce the following zones:

- ground floor masonry;

- the lower part of the window openings;

- connecting lintels, slabs and load-bearing elements.

These places have a significant load, so it is worth taking care of strengthening. It is advisable to put the mesh in 2 rows if we are talking about large foam blocks. For walls exposed to wind, a tighter installation of the reinforcing layer will be required.

Working with aerated concrete

Since this material is in demand, questions related to the reinforcement of structures often arise. To create a wall reinforcing belt, you need to use additional elements 10 and 5 cm thick. They can be purchased ready-made or cut from blocks yourself. The work is carried out as follows:

- the outer wall is glued with blocks 10 cm thick, inside they make a contour of thinner elements in order to prepare the formwork for the reinforcement;

- for insulation, a layer of expanded polystyrene or other material with similar properties is fixed;

- the basalt network is laid, observing a distance of 5 cm from the wall; special supports will be needed to fix it;

- the structure is poured with concrete for fixing.

With inter-row reinforcement, the punches are cut, cleaned of dust and a mesh is successively laid in them on an adhesive solution. The depth of the grooves made should be 2.5 cm. For wide blocks, two strips of reinforcing cloth are laid.

Working with bricks

There are three methods for fixing the mesh for cladding:

- longitudinally;

- perpendicular;

- parallel.

Most often, the strips are applied across - despite the fact that this increases the amount of consumable material and takes more time, the strength of the walls increases by 50%. The type of mesh is selected depending on the load level.

It should be borne in mind that each type of brick has its own nuances in the laying technology:

- if silicate material of the M150 brand is used, then the network is placed in every 5th row;

- for a double brick, the distance will be slightly less - after 4 rows;

- the ceramic variety requires tighter reinforcement in 3-row increments.

The mesh is planted on an adhesive solution, while you need to make sure that it squeezes into the solution at a level.

Working with road surface

Basalt can be embedded in asphalt to improve its performance. The place where the road will pass must first be cleaned of debris and leveled. After that, bitumen is applied - exactly along the width of the mesh. A canvas is placed on top, and an asphalt surface is laid on it. The final commit is in progress. When paving, it is important to observe certain nuances.

- It is not recommended to carry out work at temperatures below +5 degrees, as well as in rain or snow. After precipitation falls, you need to wait until the site is completely dry.

- Transportation of vehicles on the geogrid is not allowed.

- Basalt canvas can be laid by hand. Due to its low weight, it does not require the use of special equipment.

- Swelling, unevenness, twisting should be avoided, as this neutralizes the reinforcing effect.

The work must be planned so as to prevent the complete hardening of the bitumen, as well as the long-term exposure of the mesh in the open air without an asphalt pavement on top. Regardless of the materials used, when reinforcing, it is important to observe the technology and make sure that the canvas is located evenly. Then the basalt mesh will regularly perform its functions, increase the service life of buildings, various objects and roads.

The comment was sent successfully.