How to build a shed with a pitched roof with your own hands?

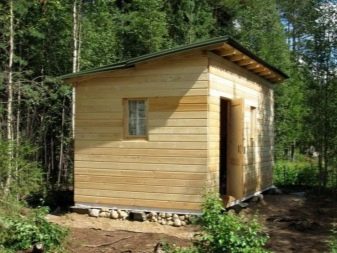

At the dacha, you cannot do without a shed, in which you can remove all gardening equipment, a hammock and light furniture. There is also a place for winter supplies. At the same time, it is not necessary to build an overall structure: everything you need will fit in a small shed with a pitched roof.

Peculiarities

A shed with a pitched roof is distinguished by its simplicity and speed of construction. It can either be built from scrap materials, or you can purchase everything you need in a hardware store, paying a reasonable price for it. This small building reliably protects household belongings from the vagaries of the weather, and even a non-professional can mount it.

Such a shed has a number of disadvantages when compared with a building with a gable roof. So, a shed roof can be carried away by a strong gust of wind, so build a structure behind the house or attach it to your country house for greater reliability.

A pitched roof will not allow the construction of an attic space, and the building itself often does not look very attractive. Modern finishing materials will help to fix the matter, with the help of which you can fit the building into the overall design of your site.

Project

First of all, find a place for a future building: it should be located either on the edge of the summer cottage, or close to the house, and for it you should choose areas that are least suitable for agricultural work.

This can be either a space remote from the house, or a heavily shaded place. It is important that it is located close to the main front of the work: this will allow you to quickly get and remove the necessary equipment. If possible, position the building on a hill, which will provide additional protection from water and extend its life.

A shed with a pitched roof will organically fit into the existing or projected complex of summer cottages. The future utility room should not interfere with the passage of vehicles and your movements around the site. For the construction of a barn, no special agreements are required, but the building must comply with sanitary and fire safety standards.

According to SNiP, the distance from your building to the house in the neighboring area is at least three meters. If you plan to place any living creatures in the annex, keep the barn four meters away from neighbors. The shed should be located a meter from the nearest outbuilding and shrub plants, two from medium-sized and four from tall trees.

When you decide on a place, draw up a drawing on paper or a 3D project on a computer in order to best imagine the dimensions of the future building, divide it into several functional rooms, and determine the device of power grids. The optimal size of the structure is considered to be 3x6 parameters - even such a modest area will allow not only an utility block to be placed inside the shed, but also to equip an outdoor shower or a summer kitchen.

If the area of the site allows, build a larger shed - 4x6 or 4x2. The spacious design is a great solution if you want to house animals or poultry. If the breeding of livestock is not provided, the building will accommodate both the summer cottage inventory, and any functional room such as a shower or kitchen, and pickles will freely take place on the shelves.

Materials (edit)

At the design stage, determine what materials you will need for construction. After all, the cost of future construction depends on them. A budget option is a wooden or metal frame structure.

In the first case, the frame is made of timber, which requires treatment with special antiseptic agents. In the second - from more durable steel profile pipes that need anti-corrosion treatment after installation.

Regardless of your preferences, you will need boards, siding or profiled sheets for the sheathing of the building. The indisputable advantage of the frame structure is not only the speed of installation and a long service life, but also the ability to transform the shed by replacing the casing without touching the frame.

The most popular are buildings made from such scrap materials as boards and wooden beams. A frame is constructed from a bar, sheathed with boards. The result is a lightweight but short-lived design, with a service life of at most five to six years. The building should be constantly updated and monitored.

If you are looking for a reliable, durable and fireproof structure, give preference to fundamental brick structures. The creation of such a change house will cost a pretty penny, but it will serve more than one generation.

Instead of expensive bricks, construction from more budgetary foam and cinder blocks is also permissible. Compared to brick buildings, they weigh less, have greater strength and heat capacity. Walls made of blocks "breathe" no worse than wooden ones, and they are also distinguished by safety and non-toxicity.

The only drawback of a block shed is an unsightly appearance, which can only be corrected by decorative finishing materials such as brick, siding, plaster, as well as natural or artificial stone.

After deciding on the material for the walls of the shed, proceed with the choice of roofing building material, which determines the angle of inclination of the roof slope. So, the angle of inclination for a soft roof is 5 degrees, corrugated board - 8, metal and piece roofing material - 25 and slate - 20-35 degrees. The angle of inclination below the indicated values is not done, otherwise it will lead to roof leaks and damage to the property stored in the building.

For arranging the roof, it is permissible to use monolithic polycarbonate sheets with properties such as high impact resistance, light transmission and resistance to any whims of the weather.

A protective coating against ultraviolet radiation will extend the life of this material, and thermal expansion is considered its main disadvantage. This phenomenon occurs on hot summer days when the sun burns the roof. To avoid material deformation, leave a small gap when tightening each fastener.

The cheapest option for roofing is considered to be rolled roofing material. It is easy to install and designed for roofing of any complexity. But it does not look aesthetically pleasing, and it needs to be laid in several layers. For example, when the slope of the roof slope is up to 15 degrees, you will need four layers of roofing material. If the angle of inclination is up to 45 degrees, roofing material is laid in three layers. Ultimately, "layering" affects the cost of building materials.

Construction

The necessary calculations have been carried out, the materials have been selected. It's time to start directly with construction work, because it is quite possible to build such an extension as a lean-to shed with your own hands. To understand how best to do this, consider the construction process in stages.

Let's start with the foundation. The columnar foundation is designed for lightweight structures (it is especially often equipped for frame buildings). For its device, you should make a marking of the ground with a rope and pegs. Around the perimeter and in the corners, holes are dug with a depth of at least 50 centimeters.A layer of sand and gravel is poured at the bottom of each hole. Then one of the types of posts made of brick, concrete, asbestos pipes from 150 mm in diameter, PVC pipes and even railway sleepers are installed. Pillars made of pipes should be poured with concrete, and brick and block supports with a porous surface should be treated with mastic or any other water-repellent agent.

To arrange a strip foundation around the perimeter of the future building, they dig a trench 25-40 cm wide and 40-60 in depth (taking into account the depth of soil freezing in the cold season). Then sand, crushed stone and gravel are poured onto the bottom of the trench, which should be carefully tamped, plank formwork is installed, reinforcement is fixed and concrete is poured. After that, the foundation is left alone for two to three weeks, they wait until it hardens, and then proceed to the next stage of construction work.

In addition to the well-known types of foundations, it is permissible to arrange the base from car tires. In addition to sheds, gazebos, baths, garages and even summer kitchens can also be built on tires. At the same time, the structures to be erected should be light and small-sized, since the construction of large objects on such a foundation can lead to unpredictable consequences.

In general, tires are a budget and affordable material that can be easily installed. It does not allow moisture to pass through, protects the building from cracks, and also dampens soil vibrations, which makes it indispensable in any seismically unstable area.

The tire foundation can be columnar or monolithic.

The first is set as follows:

- Garbage is removed from the construction site and the fertile soil layer is removed.

- If it is planned to install a buried base, wells are dug for tires.

- Pegs are driven in along the perimeter of the future building, and then it is checked that they were installed in the same plane by measuring the diagonals.

- Bars are installed, and then tires are put on them (or they are laid in pits).

- The outer surfaces of the tires are leveled so that they are level.

- From the inside, the tires are filled with crushed stone, gravel and any other dense material. The distance between the tires is filled in the same way.

- The next step is to pour concrete mortar inside the tire. The cement should be periodically moistened and covered with polyethylene.

- After that, you should cover the tires with roofing material, mount a plank formwork with a height of 100-150 millimeters, install reinforcement inside and pour concrete.

Recessed or raised monolithic tire foundations are ideal for areas with high groundwater levels.

Arrange it like this:

- Remove a layer of soil 20-30 cm deep and level the construction site horizontally using a leveling tool.

- One or two layers of tires are placed close to the area of the marked area. The height and diameter of the tires have a positive effect on the shock-absorbing and waterproofing properties of the material.

- The inner parts of the tires and the intervals between them are filled with crushed stone and gravel (any dense building material is also suitable), carefully tamped and poured with cement.

- Roofing material is spread over the entire area of the laid tires and reserves are left on all four sides of the future foundation.

- Formwork with a height of 100-150 millimeters is mounted along the perimeter of the future structure, taking into account its partitions. Metal fittings are installed in it and poured with concrete.

After arranging the foundation, they begin to create the lower strapping, made of a bar with a section of 100 by 100 or 150 by 150 millimeters. To do this, the ends of the timber should be chopped off by the "half-wood" method and connected with metal staples.

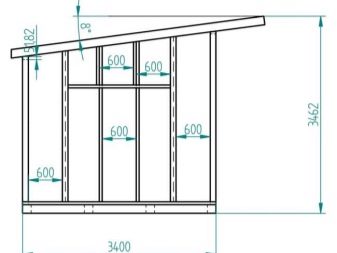

The next stage of work is the assembly of the frame: to do it, install vertical posts and level them using a building level. Installation of the front wall is carried out so that the desired angle of inclination of the roof is obtained.The racks should be strengthened with temporary slopes and at the same time outline the location of future windows and doors, so that later you do not suffer from sawing them out.

Then the floor logs should be mounted on the frame, attaching them at intervals of 60-120 centimeters. The floor is laid using edged or specially grooved boards.

After that, floor beams are installed on the supports (the so-called top strapping or Mauerlat) and the roof begins to be mounted:

- Calculate the length of the rafter by adding double-sided overhangs to the spacing between the walls. Often this parameter does not exceed 400-500 centimeters.

- They begin to make a control rafter leg: they take a board, cut it to the desired length, try on and outline a place for fastening.

- The required number of rafters is made according to the sample.

- Installation of the front and rear rafter legs is performed, and then the thread is tightly pulled between them.

- The rest of the elements are installed along the thread with a step of 600-800 centimeters, fixed with nails and steel corners.

- Waterproofing materials such as film or roofing felt are attached to the rafters with an overlap using a construction stapler.

- A rack lathing is laid on the rafters, the pitch of which is determined by the characteristics of the roofing material.

- The final stage of work is the flooring and fixing of roofing materials in accordance with the instruction manual.

Construction completed. It remains to install doors and windows, as well as treat the barn with protective equipment and sheathe it with any finishing material to give the building an aesthetic look.

Successful examples and options

The dark paneling of the small building contrasts with the vibrant greenery and potted flowers. The optimal solution not only for storing summer cottages, but also a worthy addition to the design of a summer cottage.

The compact building does not have an unusual design, but it is convenient to place everything you need for a garden and a vegetable garden in it. An excellent option for owners of medium and small plots.

The structure attached to the house will shorten the path from the kitchen to the food supplies and from the vegetable garden to the necessary equipment. A skillfully organized space will allow you to arrange all the attributes of a summer holiday in such a way that at the right time they will immediately be at hand. And under the roof of a barn equipped in accordance with all the rules, they will be preserved in proper form.

For information on how to build a shed with a pitched roof, see the next video.

The comment was sent successfully.