All about self-tapping screws

During construction work, various fasteners may be needed. The quality and strength of structures largely depends on them. Self-tapping screws are a popular option. These fasteners allow you to make strong and durable connections of materials. The article will discuss what such details are, what types they are.

What it is?

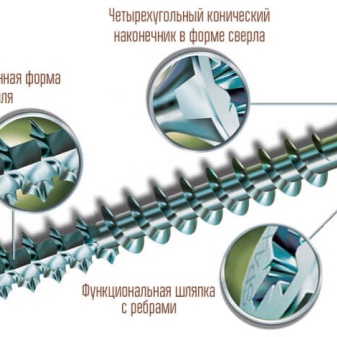

A self-tapping screw is a metal product consisting of a cylindrical threaded rod and a head. For the manufacture of such fasteners, stainless steel, brass, carbon steel are used. Various types of self-tapping screws can be used to connect structures made of plasterboard, metal, wood, window profiles, roofing, and plastic.

All fasteners in the process of creation are covered with special protective coatings.

Differences from screws

Self-tapping screws differ from screws in that for the manufacture of the former, only a high-quality steel base is used, which undergoes additional heat treatment, the latter do not undergo such processing when creating. And also screws, unlike self-tapping screws, have a larger thread pitch and a rod. In the process of using such an element, it is necessary to first prepare the holes in the material. For self-tapping screws, the seats do not need to be formed.

The screws have only two types of heads. Self-tapping screws can be produced with a variety of tips. The latter can be used for fastening various structures and materials, including metal, concrete, wood.

Species overview

Such self-tapping screws can be of several types, design options. This must be considered when purchasing fasteners. They may differ from each other depending on the purpose, on the type of head.

By appointment

Different types of self-tapping screws can only be used for specific materials and construction work. The most common types of fasteners should be highlighted.

- Universal. These models are considered the most practical option. They are perfect for working with different materials (wood, plastic, metal). With the help of universal self-tapping screws, sheet structures can be fastened to each other.

Often they are used for fastening gypsum boards, chipboards, metal profiles of the SMK, when installing stretch ceilings, for floorboards, simple plywood, polycarbonate.

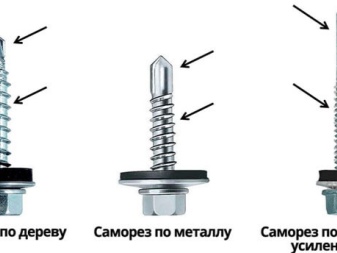

- For metal. These models can be of two types: standard with a pointed tip and self-drilling fasteners. Self-tapping screws for metal parts are made only from the most durable and resistant metals. They usually have a small thread pitch, which provides better adhesion to the material.

- For a tree. These models have a rare thread, it is better to use them for fixing not too dense wood. The length of such self-tapping screws can reach a maximum of 200 millimeters. Such fasteners for wood, as a rule, do not require preliminary preparation of the seats. During the manufacturing process, they can be covered with various colored enamels, although black or white models are more common. Sometimes these products are also used to firmly fix plastic structures. Special double-sided self-tapping screws for wood have a threaded part on both sides at once, while there is no head.

- For drywall (self-tapping butterfly). These models of self-tapping screws have an open-ended horn-shaped head. SRS self-tapping screws for fastening drywall to wood have a thread with a rare pitch and a sharp tip. And there are also models for tongue-and-groove plates, when there is a slight indentation of the edges of the front part inward, while the surface of the material is not damaged. Most of these samples are made with a special coating. Phosphated composition is used more often.

- Roofing screws. These varieties have a small rubber lining under the bonnet. It acts as a gasket to seal the hole. Typically, the tip looks like a hexagon. The end of the self-tapping screw has a drill part.

- Anti-vandal self-tapping screws. These fastening samples are similar in appearance to standard self-tapping screws. But at the same time, they have a slightly different shape of the grooves under the cap.

- Self-tapping screws for foam block. They are used for installation work with gas silicate materials, structures made of foam blocks, aerated concrete. Such fasteners are considered to be as strong and reliable as possible, as they fasten structures of large weight.

By head type

Self-tapping screws can be made with a head of different shapes, this must be taken into account when choosing suitable models. The most common are products of several types.

- Hex head models. These fixtures are similar in appearance to conventional bolts. Hex-end products are considered the most popular option for construction work. These samples are most often used for fastening massive timber structures. If such self-tapping screws are used together with additional fasteners (dowels), then they can also be suitable for fixing concrete parts. The hex fasteners are fairly easy to twist and lock into the bore.

- Fasteners with a press washer. These wide head fasteners have a larger head contact area. An additional press washer allows the most tightly pressing wood or metal surfaces, if their thickness does not exceed 10 mm.

- Versions equipped with a countersunk head. As a rule, they are used to fix wooden sheet materials, but it is also permissible to fix metal structures with them. These types can be considered universal, they have an average thread pitch. Countersunk heads are distinguished by a special reinforced stop; when they are installed in the material, it will not be necessary to apply significant efforts, they will easily enter the fastened structure.

Some of these self-tapping screws are available with a special cross-type slot. They are tightened with a Phillips screwdriver.

- Products with a hemispherical head (PShS). These metal fasteners can also be considered versatile options. They are perfect for anchoring metal frame structures to wood surfaces. And also they can be taken to attach several profiles to each other. Samples with a semicircular head are sometimes made with an additional press washer, it makes it possible to slightly press down the attached material, thereby providing a more reliable and durable fixation of the parts.

- Round head fasteners. These varieties can be used for joining metal profiles made of aluminum or soft alloys with the addition of aluminum. On the head of such self-tapping screws there is a slot (often of a cruciform shape), such a fastener makes it possible to use self-tapping screws for screwdrivers. As a rule, the metal rod of the product has a tight single-start thread.

Sometimes self-tapping screws with a reduced countersunk head are distinguished. The end will have a small diameter, but the fasteners allow you to firmly and reliably fix the fastened structures.To install such a fastener will have to apply considerable effort. Separately, we can note the ShSGD self-tapping screws. The decoding of this abbreviation means - self-tapping drywall-wood screw. They are intended for joining wood and plasterboard products. These fasteners have a fairly coarse thread. Sometimes they use pointed self-tapping screws PSh. In hardware stores, you can find special self-tapping screws pointed towards the end for attaching water panels. They provide reliable fastening of the aquapanel to a metal or wooden frame.

The fasteners are coated with a special anti-alkaline compound, which makes the product highly resistant to the cement environment. They are available with a self-centered head. Some self-tapping screws come with small decorative plugs. They are installed on the caps of the fixtures. These additional elements allow you to make the overall design more neat; parts of the fasteners will not protrude on the structures. It should be noted that self-tapping screws may differ from each other depending on the coating. They can be anodized, phosphated, oxidized, galvanized.

Materials (edit)

Self-tapping screws can be made from various metals.

- Stainless steel. It is from this material that self-tapping screws are most often created. It has good resistance to corrosion, strength, fasteners allow you to create durable connections of parts.

- Carbon steel. This material is an iron alloy with the addition of carbon. It has an increased level of strength.

- Brass. This metal is obtained by adding zinc to a copper alloy. Lead, tin, or manganese can also be included. Brass self-tapping screws are considered to be quite durable and wear-resistant.

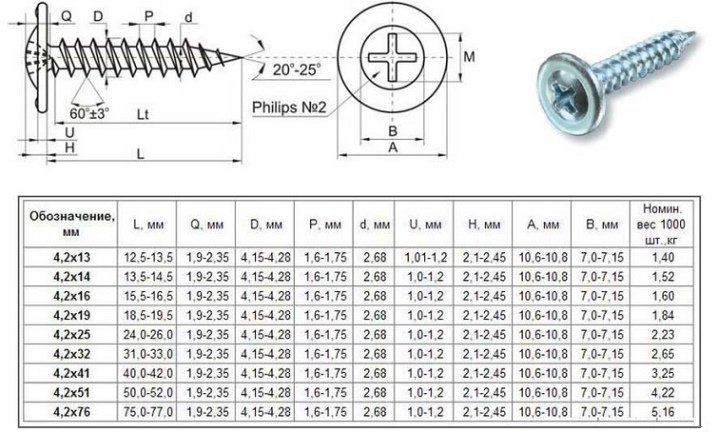

Dimensions (edit)

Before buying self-tapping screws, you need to pay attention to their size, because the quality of installation work will largely depend on these characteristics. In addition, when choosing, you need to correctly correlate these parameters with the dimensions of the material that will be fastened. Typical parameters can be 3.5x16, 3.5x19, 3.5x25, 3.8x45, 3.8x51, 3.8x55 mm.

The length of the fastener is important. For the longest models, it is over 70 millimeters.

Selection recommendations

Before buying fasteners, it is recommended to pay special attention to some of the nuances of the choice. An important place here is occupied by the type of head. If you do not want such parts to stick out of the structure, then it is better to take self-tapping screws with a secret part, after installation it will completely hide in the material. In this case, you can also purchase samples equipped with a half-countersunk head. After installation, such models will completely hide both from the outside and from the inside.

Models with a semicircular end have a large clamping area of the material. This makes it possible to fix the part on the surface as firmly and reliably as possible. Semicircular heads equipped with a press washer are considered the best option for joining sheet structures. They have an increased pressure area. Self-tapping screws with hexagons can only be installed with powerful electric tools with special attachments. But at the same time, they are considered a classic universal option.

Be sure to check the threaded part before purchasing. It can be rare, these varieties are taken for relatively soft materials. As a rule, these self-tapping screws are used to work with plastic parts, wood. Medium threads are considered standard.

Frequent threaded fasteners are also available for attaching thin metal sheet material without the need for dowels. Options with an asymmetric threaded part are best taken when assembling furniture structures (fasteners are carried out with preliminary drilling of the seats).

Different types of self-tapping screws can be used for different loads. So, there are models designed for fixing parquet floors, terraced structures, for an array.

How to choose a bat?

When installing self-tapping screws, you need to choose the right bit for the tool. Cross heads are a popular option. They are often used for black fasteners for metal, wood, galvanized models with a press washer.

Hexagonal nozzles are used to tighten fasteners with an internal hexagon. And also today, asterisk bits, slotted nozzles, bits with the PZ marking (for yellow self-tapping screws) are separately produced. In any case, the choice will depend on the type of fastener head.

How to twist?

In order for the connection to be strong and reliable, you need to install the self-tapping screw correctly. The mounting technology may be different depending on what material is being bonded. When connecting concrete blocks, the installation will be carried out using dowels. It is in them that the self-tapping screw is placed. If you will screw fasteners into tiles, screeds, bricks, then you should use the same technology as for concrete, but you can take a regular drill with a special drill, and not a perforator. For screwing into solid metal parts, holes must be pre-formed, their diameter must be either equal to the diameter of the fastener, or slightly larger than it. If you are going to mount a self-tapping screw into a wooden surface, then you can use a drill, while the diameter of the drill must match the diameter of the rod.

When working with drywall sheets, markings are first made with a pencil. For installation, you can use a screwdriver. First, you will need to screw in at the highest possible speed, then it should be slightly reduced. If there is no such tool, then you can take a regular screwdriver. An additional metal bracket can be attached to create a strong and even bond. In the process of working with self-tapping screws, you can put on a special magnetic bracelet on your hand to fasten metal parts. It will allow you to keep all the elements at hand, while they will not get lost and will not roll. After fixing the screws, you can paint them with powder pigment.

How to unscrew?

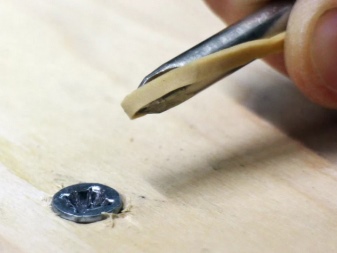

To remove the self-tapping screw from the material, you can take thin pliers. The tool needs to grab the end of the fastener and unscrew it by gradually turning it counterclockwise. If the self-tapping screw is at too great a depth, and it is impossible to get it out with pliers, then you should take a chisel. When extracting a part from a concrete surface, it is first necessary to make small cuts with the help of a grinder in order to grab the element with another tool.

When removing self-tapping screws from metal structures, you will have to make additional small holes next to the seat. After that, the self-tapping screw is grasped with pliers and pulled out with rotational movements. If the slot is torn off, and the cap itself is intact, then they take a small piece of rubber. It is placed on the screw head, then they rest against it with a screwdriver and gradually begin to unscrew the part.

The rubber allows for better grip without breaking off the tool.

For information on how to properly tighten and unscrew the self-tapping screw, see the next video.

The comment was sent successfully.