Choosing and attaching a dowel for hollow bricks

The dowel for hollow bricks allows for a reliable connection with the base material of hinged facade structures and interior items. An overview of the types of special fasteners allows you to choose the right option for almost any purpose. But before starting work, it is worthwhile to study in more detail how to fix a dowel-nail, a "butterfly" or a chemical version in a brick with voids.

Peculiarities

The main task that the hollow brick dowel must solve is reliable fixation in the material. The presence of air cavities makes it possible to increase the heat capacity of such structures. But a brick with voids is more fragile inside, the partitions between them have thin walls, if the fasteners are installed incorrectly, they can be easily broken or crumbled. Installing an anchor bolt with a nut into it will not work - the hardware will simply turn, but will not fix inside.

It is necessary to use special dowels that are longer, but do not exceed the width of the building block.

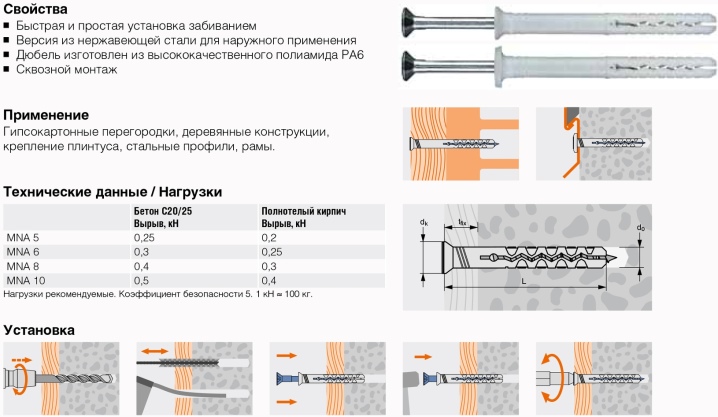

Another distinguishing feature of such fasteners is the increased size of the spacer area. It provides sufficient emphasis on the walls of the brick, excludes turning in the hole during the installation of a bolt or self-tapping screw. The size range varies from 6 × 60 mm to 14 × 90 mm. Manufacturers recommend using exclusively universal or self-tapping screws for wood in such a connection.

What are they?

There are several main types of dowels used when working with hollow bricks. The most common options should be considered in more detail.

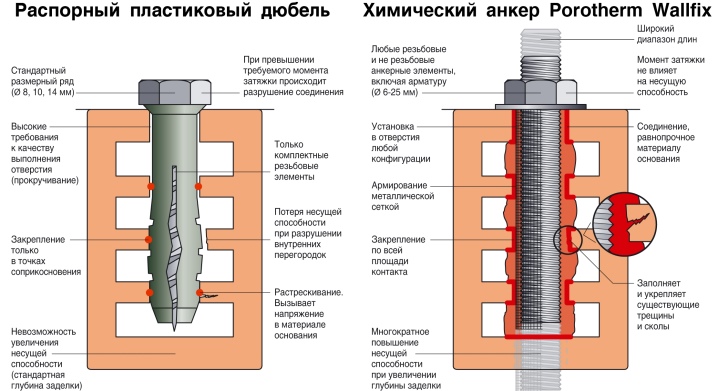

Chemical

A type of dowel in which the traditional spacer construction is supplemented with a fast-setting aggregate. The mass of the substance introduced into the joint prevents the rotation of the fastener in the hole, creates a universal strong fastener that can successfully withstand the most intense loads. The composition of a chemical dowel includes components that use the forces of adhesion, cohesion, which increase the strength of the connection by 2.5 times in comparison with the usual one.

Chemical anchors are a multi-component connection in the form of a metal sleeve with a thread inside.

And the structure includes a reinforcing bar and a stud of the corresponding diameter with a stainless or galvanized outer surface. The adhesive is in a special capsule inside, which is triggered under pressure, or it is squeezed out separately into a hole drilled in the wall. This component fills the voids inside the brick, quickly polymerizes, and is not inferior in strength to concrete.

Dowel nail

The simplest solution, well known to every builder. In the case of hollow bricks, the nail dowel can be used to fix lightweight structures that are not subject to significant loads. Professional builders do not use such fasteners because they are not securely fixed in hollow structures. It will be much more effective to use other types of dowels.

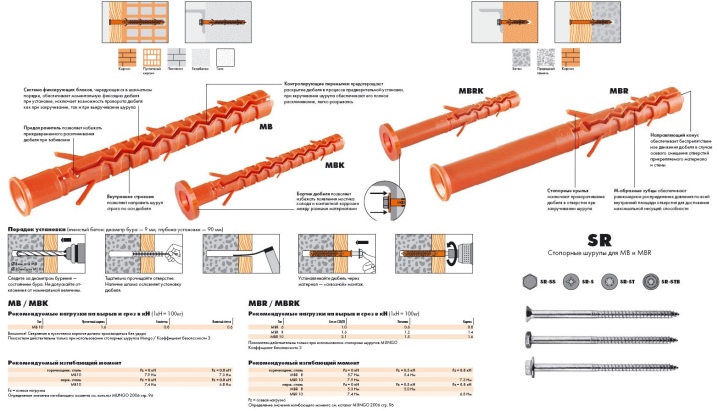

Façade

A type of fastener used on the exterior walls of hollow brick buildings. Facade dowels are used for fastening sound insulation, waterproofing. There are anchor and disc varieties. The first is used when attaching brackets, on which the ventilated sheathing is then hung.Dowels help to securely anchor mineral wool and other materials to form facade insulation.

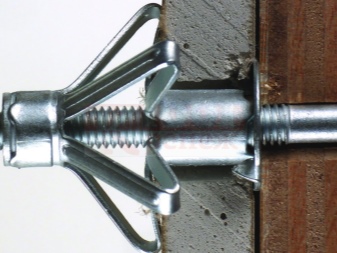

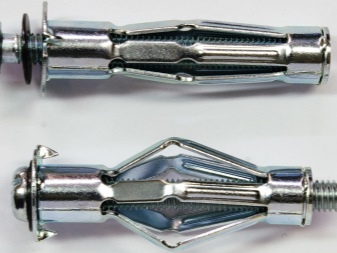

Steel "butterfly"

A type of dowel designed specifically for attaching objects to a surface with voids inside. When a screw or self-tapping screw is screwed into the hollow cylinder, the body expands, reliably jamming the fasteners inside the brick.

The design provides a safety cuff that keeps the cap from going too deep.

This dowel is suitable for fixing objects that create medium loads on the wall surface. When selecting fasteners, it is important to take into account the ratio of the cavity sizes and the thickness of the butterfly opening.

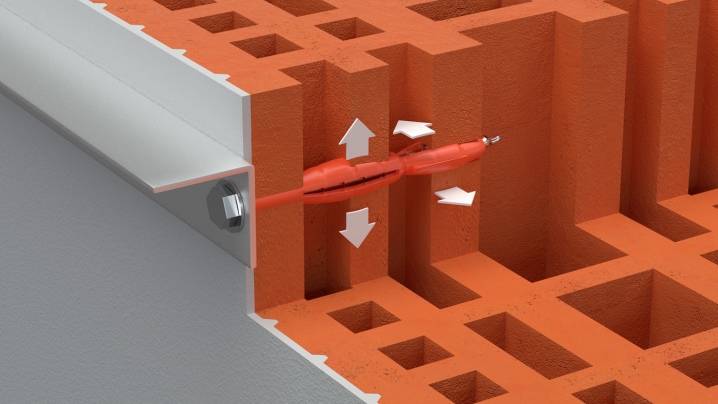

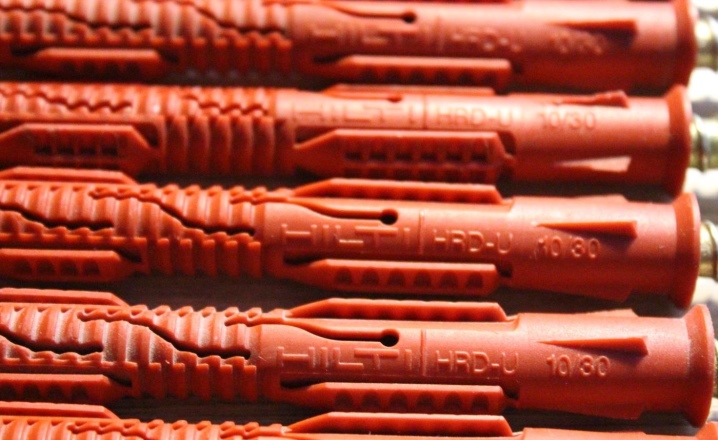

Nylon

Similar to the previous version, but designed for lower loads. It is made of polymeric materials and is versatile. With the help of nylon dowels, timber, facade cladding, shutter systems and frames are attached to the hollow brick. For such fasteners, the thread is oriented towards wood screws or metric screws, studs. When screwing in the screw, the elongated tail tip twists, forming a knot that prevents the fastener from moving in the hole.

How to fix?

Fastening dowels into hollow brick has its own characteristics. The metal or nylon butterfly strut option is easy to install and involves a number of steps.

- Surface marking. It is carried out with a simple pencil, you can make a small indentation with a nail to facilitate positioning of the drill.

- Hole preparation. In a bumpless way, with a drill with a victorious drill, the place of the future attachment is neatly formed. It is important that the tool is located strictly perpendicular to the wall; a stop stop is used to maintain the desired depth. The size of the drill must fully match the diameter of the dowel so that it goes in with little effort. After reaching a depth of 1 cm, you can increase the speed of the drill.

- Cleaning. Traces of brick chips are removed from the drilled hole; it is better to use a vacuum cleaner.

- Fixing the dowel. Its end is placed in the hole, then the entire cylinder body is carefully hammered with a rubber tipped hammer. A self-tapping screw or other fastener is screwed in to the end or with a gap of 2-3 mm if suspension loops are supposed to be used.

If the dowels were selected correctly, they are intended specifically for bricks with hollow holes in the structure, they will not turn when screwing in the screws.

Fastening chemical dowels has its own characteristics. Here, a plastic or metal threaded sleeve is used, into which fasteners are installed - this design differs little from its classic counterparts. In addition, a chemical adhesive is used, mainly with a filler in the form of cement. It is most often two-component, it can be in ampoules, cartridges, tubes. The package includes 2 compartments: with glue and hardener.

Simplified installation looks like this: the ampoule is placed in a prepared hole, then a rod is inserted into it. Under the pressure of the screw-in fasteners, the shell ruptures. The adhesive and hardener mix and polymerization begins. The curing time of the material and the curing time of the joint is indicated by the manufacturer on the packaging.

When buying chemical anchors in cartridges and other reusable packaging, the preparation of the adhesive is done differently. The required amount of the composition is squeezed out of each package into a clean container. The hardener and adhesive are mixed, after which the compound is pumped into the drilled hole under pressure. The pre-installation of the anchor sleeve allows the free spread of the chemical composition to be contained. It provides an emphasis, is fixed on the surface of the brick walls.Such a connection turns out to be strong and reliable, withstands significant loads, and can be used when working with ceramic and silicate blocks.

Which dowel to use for hollow bricks, see below.

The comment was sent successfully.