All about floorboard screws

When decorating the interior of the room, special attention should be paid to the installation of the floor covering. To do this, use special fasteners. Most often, self-tapping screws are taken for the floorboard. Today we will talk about what features they have, and how to install them correctly.

Peculiarities

Floorboard screws are a part that looks like a nail. Moreover, its rod is made with a thread of a certain pitch. On the head of the element there is a special small recess-slot, with the help of which it is screwed into the material.

For the floorboard, special self-tapping screws are used. They are produced with a small cutter at the end. In addition, these models do not have a thread at the top. In the process of screwing in, the screws will not split the wooden base.

When using such fasteners, it will not be necessary to form special holes under them with a drill. All elements during the manufacture are treated with special anti-corrosion compounds for protection.

Such self-tapping screws allow you to create the strongest and most durable floorboard joints. The mount will not loosen. It is not recommended to use conventional fasteners for installing floors.

How to choose?

Before you buy screws for a floorboard in a hardware store, you should pay attention to several important nuances of selection. So, be sure to look at the dimensions indicated on the package. The following values are considered standard:

- 3.5x35 mm;

- 3.5x40 mm;

- 3.5x45 mm;

- 3.5x50 mm.

And before buying, you need to consider the type of board that you will use for finishing the floor. If you are planning to take a special decking, then you should purchase models with a dense galvanized coating in silver or gold.

Decking is used for the construction of various structures, which will later be located in the open air. It will be exposed to various adverse weather conditions, so the most durable and reliable varieties with protective coatings will be suitable for installation.

It is not recommended to use simple options, as soon the connection will be destroyed.

Besides, self-tapping screws for fixing a terrace board are produced with a special thread, which ensures the attraction of structural elements, with a countersunk decorative head equipped with milling ribs. This design provides an easy and most accurate entry of the tip into the wood. Models for such a board are mainly made of high quality stainless steel.

Self-tapping screws for parquet material are sold separately. They differ in length (it ranges from 45 to 80 millimeters), diameter (3 or 4 millimeters). These dimensions make it easy to attach the part to the tongue.

And also self-tapping screws for larch parquet flooring differ in the shape of the head. It allows the element to be easily and quickly embedded in the material during installation work. The thread geometry is designed in such a way that screwing in the fixture is as easy as possible. A special sprocket under the sprocket prevents the bit from slipping and tearing off the edges.

Simple floorboard screws are a classic option that can be used with different flooring models. Such varieties are screwed in immediately through the front surface if the floor is without a tongue.In this case, the length of the self-tapping screw should be 4 or 5 centimeters more than the thickness of the fixing parts.

If in the future the surface of the boards will be decorated, then special oxidized models can be used. When treating the flooring with construction varnish or wood-based oil, it is better to use yellow fasteners with small caps.

These fasteners for a tongue-and-groove base are slightly different, because in this case, the fastening takes place already through the tongue. They are shorter and thinner than the previous version. After all, such models are screwed through a small ledge on the surface. An element that is too thick can simply split it.

When choosing, it is worth considering other nuances. It is necessary to check the quality level of the slot and thread on the screws in advance. The threaded part must be evenly spaced along the length of the rod, and at the same time all the turns must be of the same thickness and must be placed at the same angle. A high-quality slot will also be flat so that the screwdriver can easily enter it.

Be sure to look at the cover of the self-tapping screw. Some samples are produced, in general, without protective applications, they differ in a lower cost, but this option is not reliable, it can quickly fail, which will lead to the destruction of the connection.

Some products are produced with an oxidized coating. Such samples are black or gray. They have a good level of strength and durability.

The most reliable varieties are considered galvanized. They have a golden or silver color. This type of coating provides excellent protection against moisture and other negative influences. Products made from stainless steel are also the most durable and resistant, but they also have a high price tag.

The type of cap also plays an important role in the selection of suitable self-tapping screws for the floorboard. Samples with a wide end allow you to press the wood sheets as tightly as possible, standard products provide good fixation of the material, devices with a beveled head at an angle of 60 degrees go well into the back.

Terms of use

In order for the self-tapping screw to ensure a durable connection of the structure, it must be installed correctly. As a rule, such fasteners are used in order to fasten boards to logs for installing a continuous covering.

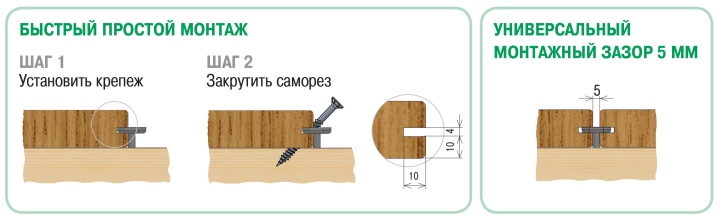

Anyone can fix such screws. These fasteners can be used for floor mounting. To do this, you first need to screw the hardware into the tongue. In this case, an angle of 45 degrees must be observed. During installation, such fasteners will loosen much less than conventional nails.

The comment was sent successfully.