All about black self-tapping screws

Black self-tapping screws are probably one of the most common products in construction stores. Many of the home renovation professionals consider them versatile and suitable for all types of work. But sometimes there are times when it's best not to use them. From this article, you will learn the advantages and disadvantages of black self-tapping screws, when they can and should be used, and when you should give up in favor of others.

Peculiarities

The term "self-tapping screw" is an abbreviation for "self-tapping screw". They became widespread in the 60s of the XX century. The main feature is that there is no need to pre-drill a hole before screwing them into the material.

Self-tapping screws coated with a special solution of phosphates are called black. For the convenience of screwing, there is a slot in the cap: usually it is cruciform, but sometimes it is also straight. The purpose of self-tapping screws is to fasten various materials together. All parameters of these products are reflected in GOST 1145-80 and 27017-86. These standards define the shape, material and thread pitch of this fastener for soft and durable materials.

Advantages and disadvantages

For black self-tapping screws, it does not matter at all which base to "bite into", be it wood, drywall or plastic: in all these cases, they will perfectly cope with the task. That is, in this regard, they are quite universal. But before using them for repairs, you should be prepared for some not very pleasant qualities.

In general, black self-tapping screws have a lot of useful qualities. They are very durable, easy to use, easily fit into soft surfaces, and are inexpensive. But despite all these great qualities, there are also bad sides.

Let's consider the main ones.

- The coating is not particularly durable, and if you use such fasteners outdoors or in high humidity conditions, it will rust quite quickly. To prevent corrosion, it needs to be treated with something additionally.

- They do not cope with the bending force, they break almost immediately.

- Designed for fastening structures of light weight. If they are impressive, the screws are likely to fail and break.

- Excessive pressure on the cap can damage the splines. It will be very difficult to unscrew the product later: you will have to drill it out or screw in a new self-tapping screw nearby.

- If the self-tapping screw is of considerable length, then when screwed in, it will most likely bend. Therefore, you must first drill a hole.

However, these disadvantages are typical for wood and metal.

And in working with other materials, black self-tapping screws proved to be excellent.

Types and sizes

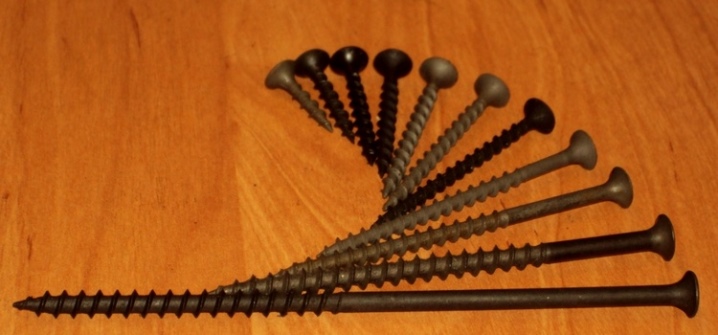

The key difference between such products in appearance is the thread pitch. There are three main types.

- A wide distance is typical for products used when working with soft materials. With their help, wood, drywall, plastic, chipboard, fiberboard, MDF are joined.

- Small thread pitch is used when working with especially hard wood species, hard plastics and metals.

- Multi-start thread. In such products, both methods of cutting turns alternate. They are designed for applications where materials of different densities need to be bonded.

You can also find hardened self-tapping screws with a drill at the end or with special cutting edges. Still such fasteners are divided according to the type of head. There are quite a few of them (hidden, half-hidden or protruding), sometimes they are found on a turnkey basis (hex).

The dimensions of the screws are indicated in the GOST table developed in the 80s of the last century, and they are still valid. You can also find very small self-tapping screws, the people call them seeds. But they are quite rare due to their low demand.

Based on demand, manufacturers fill the market with the most popular sizes. The most widely used products are 45, 50, 60, 70 mm long. The range of diameters is large: from 1.6 to 12mm. But everything is dictated by demand, and in terms of diameter, the most common sizes for metal are 3.5 and 3.9, for other materials - from 3.5 to 4.8 mm. For drywall, 4x6 is usually used.

How do they differ from yellow ones?

The most important difference between yellow and black self-tapping screws is the type of coating. Zinc is mainly used for this purpose. Because of this, they differ in price, but they can be used in any conditions, and they will last much longer.

How to choose?

When choosing self-tapping screws, you should pay attention to:

- the type of material that is fastened together;

- thread pitch: the stronger the material, the smaller it is;

- the load that they have to withstand;

- length;

- diameter: if it is too large, soft products may crack, and the self-tapping screw will not pass through dense layers;

- type and shape of the cap;

- how the slot is made;

- the manufacturer, because quality is also important.

Each master chooses for himself which self-tapping screws to use, since much depends on personal preferences.

But Black is really very good in certain conditions, the main thing is to be smart about his choice and correctly assess the intended place of their use.

For detailed information on black self-tapping screws, see the video below.

The comment was sent successfully.