Liquid roofing material: description and application

New generation waterproofing materials are gradually replacing the classic rolls. This category includes liquid roofing material applied to the surface of building structures in a fluid state - this is its main field of application. It is worth talking in more detail about what it is, what is the consumption per 1 m2, how to dilute and how to use liquid roofing material.

What it is?

Under the trade name "liquid roofing material" are hidden polymer-bitumen compositions used as a coating for vertical and horizontal building structures. It is completely similar to the roll materials of the same name, but has a different structure.

Liquid roofing material is a material with a thick, viscous consistency, supplied in containers made of metal or plastic. In terms of its fluidity, it a little resembles plasticine or mastic, it requires the use of additional components when thickening. In the production of liquid roofing material, the basis of the composition is always bitumen, which occupies most of the volume.

To it are added a plasticizer, polymer and mineral fillers. The best option is PBK-1, which includes thermoplastic elastomer, which retains the properties of the coating when exposed to frost and sunlight. For application, MBI or MRBI options can be used as a primer. It is necessary to use liquid roofing material in a diluted form. In this state, it acquires improved fluidity and is suitable for application as a primer. The topcoat is made thicker and more dense.

Any type of coating is applied exclusively in a cold way, without additional heating.

Where is it used?

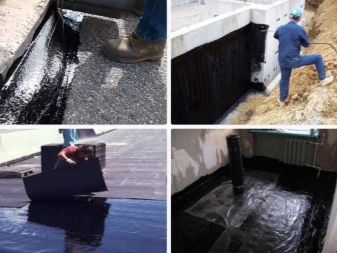

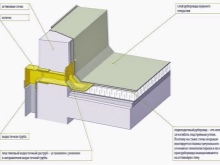

The main areas of application of liquid roofing material are similar to those that are characteristic of its roll-up counterparts. Most often, with the help of such solutions, the roof is repaired, which allows repairing leaks and restoring its integrity without dismantling the old coating. And also with the help of liquid polymer-bitumen compositions, it is possible to carry out waterproofing:

- foundations;

- plinths;

- basements;

- floors;

- flat roof structures.

Interestingly, formulations of this type provide an opportunity for a permanent coating device. That is, in addition to waterproofing tasks, they are capable of carrying a functional load. In this case, the layer of material has increased resistance to abrasion, it is applied up to 1-2 cm thick in several layers. For waterproofing purposes, liquid roofing material is often used to create sewers and wells. It is also suitable for repairing asphalt pavements, as a base for sealing joints and cracks.

In the case of wood and metal structures, bitumen-polymer composites are used as a protective coating. They prevent the reappearance of corrosion, help to avoid the destruction of structures under the influence of biological factors, the external environment.

How to use?

Before applying, liquid roofing material must be diluted. A special hydrocarbon composition is used as a solvent for the bitumen-polymer composition. The components are mixed to the desired consistency, thoroughly combined until smooth. For priming works, liquid mixtures are used, thick ones are suitable for applying the main coating.

The consumption of liquid roofing material per 1 m2 during application directly depends on the adhesive characteristics of the material being processed:

- for concrete, screed, old roll coating - from 0.5 to 1.5 liters;

- on asphalt and other bituminous surfaces - 2-2.5 liters;

- for metal and wood - 0.2-0.4 liters.

Application rules are quite simple. Liquid roofing material should be spread with a brush or roller only in dry weather. The processed material must initially be free of excess moisture. It is impossible to apply the mixture on a wet coating, it will flake off. To improve adhesion, all pronounced irregularities must be eliminated in order to ensure the necessary tightness.

When used as a roof covering, work is carried out in a specific order.

- Removing old flaking coating. If the composition is applied for the first time, the surface is cleaned of dust and dirt.

- Applying a layer of primer. It is evenly distributed, which improves the adhesion of the material. The primer must completely harden and dry.

- Base coat application. It is applied in layers, drying each level. It is best to work with a roller. On average, after 1-2 hours the material will set and acquire the required consistency.

Observing the correct sequence, you can ensure accurate and even application of liquid roofing material to the surface of concrete, brick, and other materials.

Review overview

According to most buyers, liquid roofing material fully justifies the funds spent on its purchase. The coating is distributed evenly, without seams or gaps. After hardening, the material acquires a smooth, uniform surface, completely impervious to moisture. Buyers note that liquid roofing material can be applied with a brush or roller, manually, without any tools, which significantly speeds up and facilitates the process of work.

Many owners have experience of long-term use of liquid roofing material - more than 3 years. According to their estimates, the product really works better than a conventional roll-to-roll analogue and retains all its properties. Such waterproofing completely solves the problem of moisture exposure to concrete and other similar surfaces. There were practically no shortcomings in the new material. Some buyers only note that the service life does not always turn out to be equal to that declared by the manufacturer. Difficulties also arise when the application technology is not followed. In this case, partial or complete exfoliation of the coating occurs.

The comment was sent successfully.