What is rubemast and how to lay it?

When building and repairing, it is useful for people to know what rubemast is and how to lay it. An equally important topic is the better to cover the garage roof - with rubemast or glass insulation. Separate aspects - technical characteristics of the material RNP 350-1.5, RNA 400-1.5 and other types of rubemast.

What it is?

At least since the beginning of the twentieth century, roofing material has been used in the arrangement of roofs. But the initial admiration for this material subsided considerably when it became clear that it was not perfect enough. Rubemast became the further development of such a coating. The introduction of special additives allowed:

-

increase the service life of products;

-

increase frost resistance;

-

guarantee resistance even with significant temperature fluctuations.

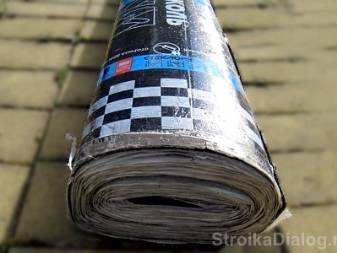

Like roofing material, rubemast is a bituminous material produced in roll form. However, it looks more attractive overall. The difference between it and its "predecessor" is quite impressive even after long-term use. The following can be used as a basis:

-

fiberglass;

-

cardboard;

-

fiberglass.

The introduction of a large amount of bitumen increases the plasticity of the material. As a result, it survives mechanical stress much better than roofing material.

The danger of cracks on the rubemast is below. The surface will be relatively smooth. Its hydrophobic properties are quite high.

Specifications

The specific weight of rubemast is sometimes 2.1 kg per 1 m2. With a typical roll size - its area is 9-10 square meters. m, it weighs 18.9-21 kg. The strength is quite high: the material breaks down only with a force of 28 kgf. The engineers managed to achieve a service life of at least 120 minutes at a temperature of 75 degrees. At the same time, water absorption will not exceed 2% in 1 day.

The brittleness of the binder component occurs in the range from -10 to -15 degrees. Most often, the roll length is 10 m. And the typical width is 1 meter. These are the parameters of the products of leading brands - for example, TechnoNIKOL. Its specific weight is 3 or 4.1 kg.

Comparison with other materials

Most often, when deciding what is the best way to cover the garage roof - with glass insulation or with an advanced roofing material, they turn to professionals. However, even ordinary consumers find it useful to know how this or that option differs. It is relatively easy to put Rubemast, and there are no problems with its installation. Its sheets are flexible and stable during installation, they can be bent even by 2-2.5 cm. Moisture does not seep under the rolled material - so no problems should arise from this side.

Stekloizol is another derivative of roofing material (or another improved subtype of it). It is more correct to use glass-insulated if in a particular area the cold starts earlier and lasts longer. Metal tiles and corrugated board are much stronger, however, it is more difficult to mount them.

Instead of rubemast, you can also use bikrost (but its service life is no more than 10 years). Geotextiles can last -7 times longer: however, it is much more expensive.

Description of species

RNP

Material of category 350-1.5 is always made with sprinkles. Its fire resistance category is G4; standard indicators are prescribed in GOST 30244. The deposited roofing material has a base with a density of at least 0.35 kg per 1 sq. m.RNP is intended to be used as a lining. Of course, it is also used to decorate flat roofs.

RNA

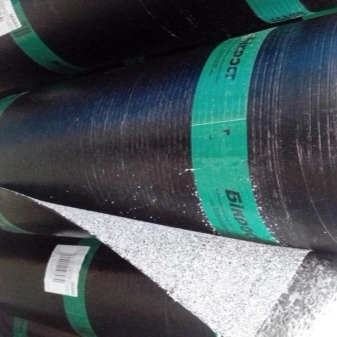

Rubemast type 400-1.5 is produced by applying a coating composition to a base in the form of a cardboard. The roofing board is pre-impregnated with bitumen. A coarse dressing is applied to the front face. Polyethylene is attached to the lower section of the roll, which further improves the characteristics of the finished assembly.

The material is excellent for all climatic zones on the territory of the Russian Federation.

HPP

In addition to the front roofing, such a rubemast can also perform a waterproofing function. Surfacing is performed on a fiberglass base. The design is suitable:

-

for the upper layers of roofing carpets;

-

for their lower layers;

-

when waterproofing the roof.

HKP

This variety is also made on the basis of fiberglass. Delivery is usually carried out in rolls of 9 sq. m. On the underside of the canvases, polyethylene is applied in the form of a film. Most often, staining is done in gray tones.

The main area of application is waterproofing.

Laying technology

As already mentioned, the use of rubemast is relatively easy and simple - but still it is worth working with it as carefully as possible and using a special technology. Errors in this case can devalue the merits of the material. The installation procedure is divided into only 2 options: in one case, the rolls are heated with a gas burner, fusing, and in the other, they are glued to the mastic. Regardless of the specific approach, the material should be kept warm in advance, at about the same temperature at which it will be laid. All installations of antennas, pipes, ventilation ducts and other elements that may interfere must be completed in advance.

Be sure to also take care of the cleanliness of the roofing surface. Order and cleanliness will greatly simplify and speed up the work. In some cases, the rubemaste coating is laid even on high-rise buildings. In this situation, the most appropriate solution is to use a crane. In advance, small pores and cracks must be saturated with a primer, best of all - on a bituminous basis.

This ensures optimal adhesion and identical thermal expansion of all layers of the roofing cake. It is recommended to prime with a roller to speed up the process. You will have to apply the primer twice. As soon as the primary mass is dry, it is necessary to apply the top layer. Accurate measurement is very important.

Rolls are rolled out in advance on the surface and they see what and how it lays down, whether it turns out to place the rubemast correctly. The overlap must be at least 20 mm. Important: you can exclude tearing of the canvases by cutting them with a special construction knife. The blanks need to be marked and numbered. As soon as the material has been laid in the designated places, you can start fusing.

The burner must be operated from the bottom up. Rubemast is pressed down immediately after warming up. At the same time, they monitor carefully so that there are no marks on the material and burns do not appear. Once the rubemast is welded, it should be rolled with a roller to prevent the formation of bumps and depressions.

Only if each layer is well-laid, it can be guaranteed that the rubemast will fit well on top of it.

Safety regulations require:

-

use balloon heating only with pressure reducers;

-

unwind the roll to be welded exclusively with a poker, but not with hands or feet;

-

do not stand against the burner nozzle;

-

tightly seal primer solvents, keep them away from children and pets;

-

use thick gloves, tight clothing and sturdy shoes.

If there is old roofing material or other material, it must be removed. The crumbling parts of the concrete substrate are knocked down with a hammer. It is useful to pre-level the surface with a cement-sand mortar. Instead of buying a primer, you can make it yourself.In a metal tank, 7 parts of 76 gasoline are mixed with 3 parts of bitumen-based mastic; this mixture must be heated without stopping stirring.

The primer is simply poured onto the main part of the surface and pulled apart with a mop. Corner sections and points of abutment are coated with flywheel brushes. The roll should be warmed up until the surfaces begin to stick. Adjacent strips are laid with the butt method. At the same time, overlap is excluded.

After placing the underlay, the roofing material is laid again. It should have a top strip for hardfacing. The initial roll is placed so that the strip is on top of the border of the underlying strips. Compaction is carried out with a homemade ramming tool.

A fragment of the covering must be cut off for laying on the sides of the roof, while providing an overlap on the previously laid covering and a bend covering the sides.

The material is heated. After laying on the side, it is sealed to ensure adhesion over the entire area. Rubemast can also be laid out on a wooden roof. You will first need to form a solid wooden crate. An additional multi-layer plywood or OSB is placed on it; the material itself is laid in several layers.

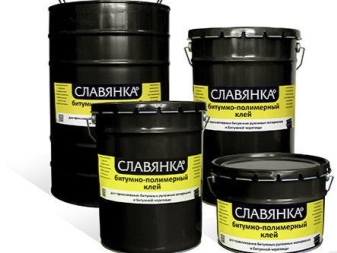

The use of mastic is also quite effective. It is better to apply it not on the rubemast itself, but on the base. The width of the connecting layer is at least 0.5 m. The unrolling of the roll in this case must be synchronized with the use of a blowtorch. The covering material is used with a margin - about 10% of it will still be spent on surfacing, overlaps and similar costs.

The bitumen mastic layer can be a maximum of 2 mm thick. The overlap in this case is approximately 8 cm. It is necessary to press down the coating until the bitumen begins to flow out of the seam. It is best to achieve this not manually, but with the help of special rollers. Experts recommend using "cold" rather than "hot" bituminous glue, because it is more gentle and reduces the risk of fire.

Transport and storage

Rubemast must not be stored or transported lying down. It is also impossible to leave it in a vertical position in several rows. Given the inclusion of bitumen in the composition of the material, strong heating can have a negative effect on it. Rolls are packed with paper strips with a minimum width of 0.5 m. Instead, cardboard strips with a minimum width of 0.3 m can be used.

The edges of the fastening strips are glued very securely. The standards allow the use of other materials, if only they guarantee the safety of the material. Loading is carried out in the most convenient way.

Large batches of rubemast are naturally loaded and unloaded using a mechanized method. With a small volume of goods sent, of course, it is easier to use the manual method.

Rolls should be placed so that the rubemast cannot move freely during transportation. They are arranged in order, composing with the highest possible density. After one or two vertical rows, a horizontal tier is placed, then this alternation (if the capacity of the vehicle allows) is repeated. It is recommended to use belts, spacers to prevent contact of a fragile load with the walls of the case. The stability can be increased by laying with sheet plywood.

Sending roofing material and rubemast is possible only in covered wagons. They will have to be loaded either manually or on pallets using forklifts. The approach of the rubemast with heating devices is not allowed. When transporting in a horizontal position, put no more than 5 other rolls on each roll. Such transportation should take place as quickly as possible; horizontal storage in a warehouse or site is strictly prohibited.

The comment was sent successfully.