Roofing material for the foundation: which one to choose and how to lay it?

The construction of any building is impossible without such a thing as a foundation, which in the case of almost any construction will be the foundation. But it is not enough just to lay the foundation - it must be protected from the effects of various natural factors, in particular, from the destructive impact of water.

And this can be done by putting roofing material on the foundation for waterproofing. Such a solution is quite affordable and will qualitatively protect the base of the building from moisture. Let's try to figure out what kind of roofing material is for the foundation and how to lay it so that it will serve for a long time.

Why is it needed?

If we talk about why this type of insulation is needed for the foundation, then it should be noted that the concrete from which the foundation for buildings is created belongs to hygroscopic materials. Moisture from the ground, due to the structure of the porous type material, rises and becomes the cause of the formation of dampness in the walls. Brick and wood begin to deform and collapse under this influence. And this may already be the cause of distortions, cracking, as well as a decrease in the durability of the building.

Besides, damp surfaces are often susceptible to fungal attack, which, combined with a high degree of humidity, can make the home unsuitable for living. And moisture protection measures can prevent the destructive effect of water on the foundation. It is thanks to them that the building will receive high-quality performance characteristics.

It is best to put roofing material as insulation, because this material has excellent properties and low cost.

Which roofing material to choose?

If it was decided to definitely put roofing material as a material for waterproofing, then it would not be superfluous to figure out which one is better to use, because it can be different. By appointment, the entire roofing material is divided into 2 groups:

- lining;

- roofing.

In this case, the lining type will be interesting, because it is he who is used for foundation waterproofing. If we talk about specific brands, then it is important to apply RKP-350, 400. The advantages of these types will be good strength and good resistance to water.

RPP-300 would also be a good solution: it has slightly worse characteristics, but nevertheless it is suitable for waterproofing the foundation foundation.

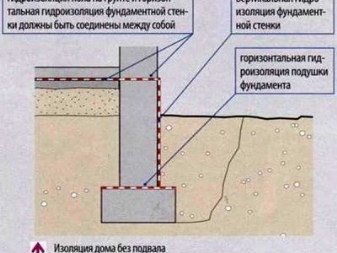

Roofing material waterproofing technology is of 2 types:

- vertical;

- horizontal.

Vertical waterproofing is required to protect the foundation at the sides. To implement such tasks, roofing material is fixed with bitumen-based mastic. But the horizontal version should be laid under the foundation and on the horizontal plane of the building. This will protect everything from moisture that goes up the earthen capillaries.

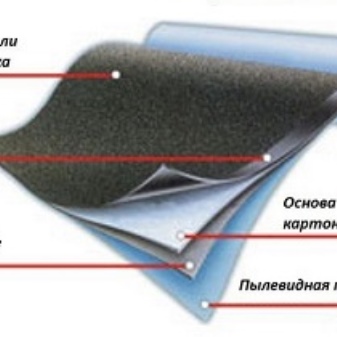

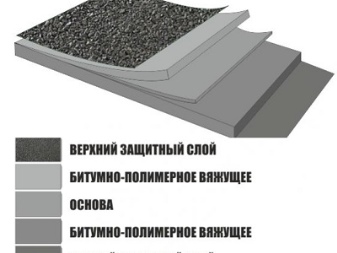

In addition, the roofing material has a cardboard base moistened with petroleum bitumen to obtain water resistance. The following raw materials are used in its production:

- non-woven material;

- fiberglass polyester type;

- cellulose based fiber.

Roofing material is also subdivided into such subspecies.

- Euroruberoid. It has a synthetic base, so it is often placed under the slate to cover the roof.

- Rubemast. It is made of cardboard and is usually used for foundation waterproofing.

- Glass roofing material. It is made of fiberglass and is used for roof insulation.

- Roofing paper. This is oil-impregnated cardboard with coarse-grained dressing on 2 sides. It is often used as temporary isolation.

Laying technology

Now we will try to figure out how roofing material is laid on bituminous mastic correctly and when attaching a mechanical nature.

For bituminous mastic

So, if it was decided to fix the material on the foundation using mastic, then first you need to level the foundation base, which will make it possible to qualitatively glue the roofing material to the surface. This can be done with a sand-cement-based construction mortar. They are usually covered with various cracks resulting from shrinkage, chips and other shortcomings.

After that, the foundation must be processed using heated bitumen mastic. Its use allows sealing cracks and improving adhesion. It is better to apply the mastic with a roller or brush. Next, the roofing material is laid. Its edges should overlap by 80-100 mm. And the excess around the perimeter of the foundation should be hidden under the vertical waterproofing.

To extend the time of application of such a coating, the application of bitumen-roofing material should be done at least twice. First, the coating is carried out, and only then a layer of waterproofing is laid. We add that waterproofing the foundation using roofing material is not carried out in bad weather, as well as in winter, because because of this, the waterproofing material can simply lose its characteristics.

When the waterproofing layer, made of bitumen and roofing material for the foundation for the frame house, cools down, you need to fill the base with soil. All work should be carried out slowly and carefully, because it will not be possible to redo them. At the same time, it is required not to deform the protection layer for the strip foundation so that its characteristics do not decrease. Note that the usual protection with a roll-type waterproofing material laid on a columnar foundation is the most common.

Correct use of roofing material will make it possible to make high-quality protection against water for a building even in difficult climatic conditions and extend its operation time.

By mechanical fastening

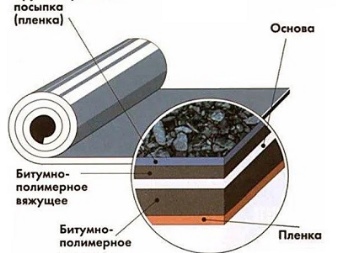

Today you can find a fairly large number of brands of the material in question. Among them are reinforced, polymer-bitumen, self-adhesive and sprayed. Almost every material will be more efficiently used when pouring mastic with subsequent attachment to the surface of the foundation.

But if you fix the roofing material using mechanical fixation on nails and slats, then this method will be the most ineffective. It is difficult to call it a method, because the roofing material is simply nailed to the foundation. But the use of such a technique would be a violation of the technology due to the fact that the insulation in this case would be simply leaky.

Moreover, the roofing material itself and the foundation will begin to collapse rather quickly. For this reason, the protective properties of the material will be very low, and the service life of the foundation will be significantly reduced.

How many layers do you need to stack?

Many are often interested in the question of how many layers of roofing material is required to be laid on the foundation for good protection. Their number should depend on the quality of the material used and on the technical conditions. If, for example, a roofing material RK is taken, which is roofing, then 1 layer will be enough, because it is more durable and has a greater thickness than an analogue of the RP type, which is a lining. Such roofing material for high-quality protection will require several layers.

Besides, a certain number of layers of the material in question may be required if it is required to reinforce waterproofing due to the presence of a high level of groundwater. Layers are installed according to the principle of alternating canvas and mastic. And when everything dries up, brickwork is made on top, which will press the roofing material with mastic for the highest quality waterproofing. Sometimes designers recommend using other materials instead of roofing material.

Polyurethane foam is very popular due to the fact that when applying several layers of roofing material, it is no longer necessary to talk about efficiency.

How can you replace roofing material?

Now you should consider materials that are often used as a replacement for roofing material. Indeed, it often happens that the properties of this material that it possesses are simply not enough. For example, in some cases roofing material cannot be used due to the fact that it quickly absorbs moisture. Therefore, analogs are used. As a rule, they are referred to as roll waterproofing. This includes glass-insulating, hydro-insulating and other solutions.

- The first is bikrost. This material is a fiberglass mat, made on a bituminous binder, it has a 10-year service life and good tear resistance.

- Another interesting material is uniflex. This is polyester or fiberglass on a polymer-bitumen basis of 2 mm thickness. Its service life is a quarter of a century, and its tensile strength is 500N. Technoelast is roughly the same. True, the thickness of such a material is 4 millimeters, and the service life is about 100 years. Its strength and resistance to high temperatures will be even higher.

All these were materials that belong to roll.

And there are also materials of a membrane and film nature.

- The first type of insulation is not glued under a brick or under a bar, but is attached. The polymer membrane is a polyvinyl chloride film with several layers. By the way, it can be made of polyester or polyethylene. Depending on the level of occurrence of groundwater, a material with a greater or lesser thickness should be used.

- Another material that deserves attention is geotextile. This is the name of a synthetic material woven from threads, or a non-woven polyester fabric.

- The polyethylene film has excellent waterproof properties. It does not require heating and various microorganisms do not appear inside it. But if the film breaks, then the waterproofing ceases to fulfill its functions. Therefore, it is better to use a reinforced film, either reinforced with a mesh-type frame, or in general penoplex. The film works best as part of a horizontal waterproofing layer.

- An excellent substitute for such materials will be bitumen-polymer mastic, which is called liquid mastic. Such a coating is one-layer and monolithic. It is very easy to spray and does not form any joints or seams. In addition, this mastic is resistant to low temperatures.

- Penetrating insulation is a good solution. This is the name of one or two-component compositions applied with a spray or brush. After application, the material penetrates the concrete pores, forming insoluble crystals. They do not allow moisture to penetrate the concrete and do not allow corrosion to appear. But such a remedy is best used in combination with something else.

- The last material worthy of attention is “liquid glass”. This is a solution with a viscous consistency, which includes plasticizers, as well as potassium and sodium silicates.

For information on how to make a foundation waterproofing with roofing felt with your own hands, see the next video.

The comment was sent successfully.