How to make a false ceiling with your own hands?

Not everyone can boast of beautiful, even ceiling coverings in an apartment or house. Many are faced with the problem of leveling old concrete ceilings. One of the best leveling options is a suspended ceiling. It is worth noting that the design and installation of a suspended ceiling is highly complex, therefore, before proceeding with this work, you should thoroughly prepare.

However, if you need the skills to perform this work to plaster the ceiling, then anyone who knows how to use a drill, screwdriver, jigsaw can install a suspended ceiling.

Peculiarities

To begin with, let's figure out the concept of "suspended ceiling". From the name it is clear that it is a certain frame structure, which is installed on an ordinary ceiling covering using special materials. It performs various functions, the main one being decorative.

In addition, suspended ceilings can serve as sound insulation, additional insulation.

The suspended structure can change the overall appearance of the ceiling and embody design ideas. The creation of a false ceiling is one of the easiest and most inexpensive ways to level a ceiling covering, which can be done without the help of specialists. Another advantage of this design is the ability to create stunning multi-tiered, curly ceilings, which can be favorably emphasized with different lighting options.

The ceiling can hide obvious imperfections (unevenness, cracks, pipes, etc.), to get rid of noise (especially important for people who prefer not to hear noisy neighbors, pets or children of neighbors), it does not darken over time, does not become covered with cracks, unlike conventional coatings.

Despite the fact that the procedure for installing a suspended ceiling is quite difficult and time-consuming, many people prefer to install a suspended ceiling themselves. You can really do it yourself, knowing the nuances. Before starting work, you should evaluate how appropriate it is to install a suspended ceiling. You must take into account such factors as the occurrence of condensation under the structure, the likelihood of rodents, insects in the space between the regular and false ceilings.

Also, you should understand that the installation of such a ceiling will visually reduce the height of the room.

If you have no doubts about the correctness of the choice, then you can start preparing for the installation.

First, you should familiarize yourself with the varieties of this design. A suspended ceiling is a system of suspensions and profiles that are installed on a regular ceiling. The material is then attached to the created structure, which will be the ceiling. Today there is a wide variety of materials, differing in structure, design, texture and color, thanks to which you can create real masterpieces.

Most often, gypsum board, plastic panels, lining made of wood, tiles and other materials are used to create a suspended ceiling. There are several types of suspended ceilings. It can be rack, cassette, solid, lattice, hemmed.Most of the suspended ceilings are installed on a structure assembled from wooden planks and metal.

Advantages and disadvantages

Suspended ceilings have a number of advantages and disadvantages. Before starting repairs, you should familiarize yourself with them in order to be ready for the result.

The advantages of suspended ceilings include:

- A quick and affordable way to hide the disadvantages of the main ceiling. This point is especially relevant for those who want to give a good look to the ceiling in old rooms with problem areas, for example, with the presence of deep cracks, depressions due to the partial absence of plaster layers. Installing a suspended ceiling will help save on dismantling and re-installing the plaster layer.

- Availability and variety of materials. For installation, you can choose the material based on quality, cost, texture, color scheme, your own preferences.

- No restrictions on color schemes, texture. Suspended ceilings allow you to embody different ideas of designers, turning the floor into a unique element of the apartment. Skillful use of backlighting will help highlight important details.

- Easy to operate. The complexity of care depends on the materials chosen. Most of them repel dust, do not allow moisture to pass through. For washing, you can use ordinary detergents.

- Installation of such a ceiling helps to hide wires and other elements of communication systems (alarms, ventilation, electrical wiring, etc.), increasing the attractiveness of the ceiling.

- Simple complete or partial disassembly if necessary.

- Long operational life, subject to the rules of operation. A suspended ceiling can last from 15 years with proper installation and proper care.

- Possibility of installing additional ceiling-mounted lighting fixtures.

- Soundproofing to prevent the penetration of noise from neighbors.

- Heat preservation, fire safety, resistance to temperature extremes.

There are also a number of disadvantages that can affect the decision to install this structure:

- Changing the height of the apartment. A slight change in ceiling height becomes a significant problem for small spaces.

- Quite a high cost compared to the maintenance of a conventional ceiling. When evaluating this item, it is worth considering the difference in care. An ordinary ceiling needs to be periodically put in order using whitewash, paint. The worse the condition of the ceiling, the more difficult it is to bring it back to normal.

The suspended ceiling is durable and does not require constant maintenance.

- Dependence on external conditions. Most of the suspended ceilings do not tolerate high humidity, in case of water penetration into the structure, partial or complete reconstruction of the ceiling elements will be required.

- Favorable conditions for the reproduction of rodent insects. In some private and multi-storey buildings, cockroaches, mice, and rats can start. If they get caught in the space between a regular ceiling and a false ceiling, it will be difficult for you to get rid of them.

Materials and tools

The future result depends on the choice of materials. Therefore, it is worth paying special attention to the selection of elements for creating a false ceiling.

To install it you will need:

- Aluminum profile of two types. The guide is needed for fastening around the entire perimeter of the room, it serves as a frame for other elements. The ceiling profile is used for further installation of the external ceiling material on it.

It is advisable to use elements of a set of profiles from one manufacturer.

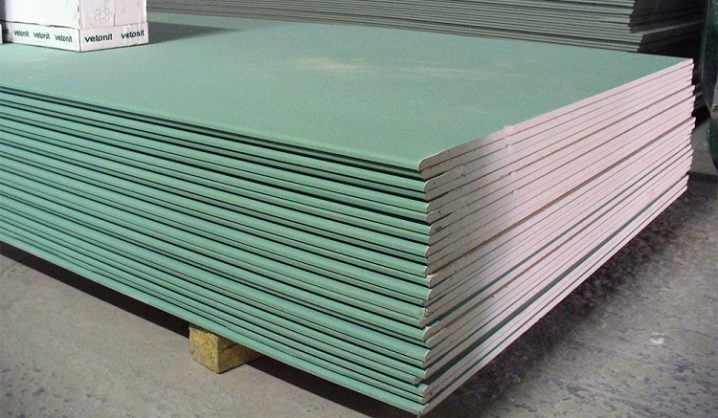

- Drywall. The choice of drywall depends on the type of room; the peculiarities of the operating conditions of the ceiling should be taken into account. For rooms with high humidity, it is recommended to choose a green gypsum board. This type of drywall is moisture-repellent, so it does not lose its shape and quality when it comes into contact with moisture.

For living rooms, you can take gray sheets with a thickness of 8-10 mm. Do not choose thick materials, the thicker the sheet, the greater its weight, which means that additional elements will be needed for its installation.

- Fasteners. Installation of a false ceiling is impossible without them. Fasteners are needed to fasten profiles and external materials. For fastening the profiles, you need straight hangers, "crabs", extension cords.

To mount the suspensions, you will need 8x10 mm dowels, 4.2x51 mm galvanized screws. To install GKL sheets, you need 25 mm self-tapping screws.

In addition to the materials, you need to prepare the following tools:

- pencil;

- roulette;

- building level to determine the marking line for the profile and drywall, usually 2.5 m;

- painting thread;

- electric drill or screwdriver;

- perforator with a drill;

- construction knife;

- grinder for metal carving;

- scissors for metal carving.

After installing the false ceiling, you will need materials for finishing:

- putty for filling seams, gaps, irregularities;

- serpyanka;

- acrylic based primer;

- fine-grained sandpaper;

- medium-sized spatula;

- paint brush or roller for painting;

- material for sound and heat insulation;

- porous sealing tape to ensure the most tight contact between the ceiling and the base.

Payment

The amount of materials required is affected by the size of the ceiling area:

- The number of guides depends on the perimeter of the room; to calculate, you need to know the width and length of the room.

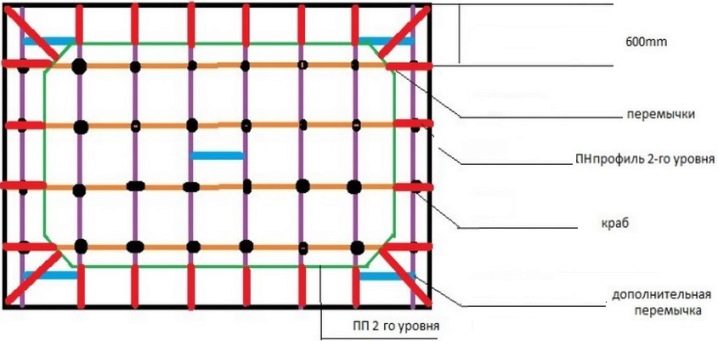

- The ceiling profile is installed along its entire length every 60 cm.

- Plasterboard must cover the entire ceiling area; to calculate the number of sheets, the ceiling area should be divided by the area of 1 sheet (about 3 square meters).

- The number of fasteners depends on the number of connections proposed.

Construction device

No work, especially such a complex and responsible one, takes place without preliminary planning and exact correspondence with technology. Before starting the installation of the false ceiling, you should make a construction drawing on paper and purchase accessories.

The markup must be competent and accurate so that in the future you do not have to redo all the work from scratch.

To create a drawing, it is necessary to measure the length and width of the room as accurately as possible. To begin with, using a level, a horizontal line is drawn at a distance of 10-15 cm from the ceiling level. The exact height depends on the type of luminaire selected (surface mounted, recessed, etc.). At this stage, you must determine the degree of curvature of your ceiling in order to account for this when installing a suspended one. This is an obligatory stage of the work.

After calculating the height and perimeter of the ceiling, you should draw longitudinal and transverse lines around the perimeter in increments of 60 cm. You should get even squares. The hangers will be attached on longitudinal lines, they are marked with dots every 60 cm.

Mounting

Installing a false ceiling with your own hands does not mean working alone. You will need one or more assistants to get the job done.

It is worth starting with a simple single-level ceiling.

First stage

The first step is to prepare the premises. You must remove everything unnecessary from the room so that nothing interferes with your work. Check the walls carefully, if necessary, they need to be leveled. Carry out all the necessary communications so that you do not have to do this after installing the ceiling.

If there are gaps in the ceiling, they must be repaired. Make sure the ceiling surface is dry, if necessary, let the room dry.

Layout work

Before starting work on the installation of the ceiling, you must think over the placement of the lighting fixtures. The level of the ceiling height will depend on the type chosen. In the presence of spot lighting, the ceiling must be lowered 3-4 mm below the height of the luminaires; for an overhead source, it is required to lower the level by 5-10 cm.

If the main ceiling was not level, the lowest point should be determined. It is she who will become the reference for the marking. If you select any other point, the suspended ceiling will be tilted.

After marking, a flat horizontal line is drawn along the entire perimeter. This can be done using a rule or a long level.

Base fasteners

According to the markings made, holes need to be drilled at intervals of 35-40 cm. Then you can start assembling the ceiling structure. In this case, a guide profile is first applied, plastic dowels are inserted into the drilled holes. Self-tapping screws are screwed into the dowel, preferably for wood.

Please note that the strength of the suspended ceiling is directly related to the quality of the fasteners, so you need to drill deep enough holes. The depth to be drilled is usually 40 to 80 mm.

After completing the installation of the guide profiles, the rack (ceiling) profiles should be installed along the entire length and width of the ceiling part. They are laid every 60 cm, their ends must be on the side guides of the profiles. It is worth noting that for the simplicity and strength of the base, the length of the rack profiles should not exceed 2.5 m. In general, their length should correspond to the width of the room minus 1 cm due to the side guide profiles.

Rack profiles are inserted into the center of the marks, then they are fastened with self-tapping screws with a press washer to fix the fastening. Suspensions are used every 40 cm to avoid ceiling sagging, they provide reliability and rigidity of the structure.

Laying the wiring, preparing the installation of the chandelier

The preparation for the installation of lighting fixtures depends on their type. If you have chosen spotlights, then you will need to drill holes in the drywall in the right places. Please note that the hole must not enter the profile. If you plan to install a chandelier, then you will need additional fasteners to the ceiling or to the ceiling base.

To avoid sagging, additional suspensions and inserts are needed at the installation site of the chandelier.

All wiring must be hidden in a PVC corrugated hose.

Insulation laying

If you want to improve sound insulation and insulate the ceiling, you will need to install the insulation over the frame. The insulation is attached to the main ceiling using mushroom-shaped dowels.

Drywall Fasteners

Before starting the fastening, you need to cut out the panels from the drywall to cover the ceiling area, for this you must strictly adhere to the step-by-step instructions. First of all, lines are marked with a pencil, then they are cut along the marked lines with a construction knife.

Drywall is attached with self-tapping screws to the profile, the distance between the self-tapping screws is 20-30 cm, such an indent must be. The edges of two sheets can be assembled close together, or you can leave a small gap between them (up to 5 mm). The heads of the self-tapping screws need to be drowned in the sheet by 1-2 mm, then they are covered with putty.

Then they can be hidden in a glazing bead, covered with curtains, etc. If the heads remain uncovered, then over time they will rust and spoil the aesthetic appearance of the ceiling. All cracks are clogged with putty, and a serpyanka is glued at the joints with the help of "Perlfix".

As you can see, assembling a suspended ceiling with your own hands is not at all difficult if the assembly takes place in strict accordance with our recommendations.

Decorative works

After the installation of the suspended ceiling is completed, the next phase begins - decorative finishing. Now it can be pasted over with wallpaper, painted, covered with panels made of plastic, wood, etc. As in the previous stage of work, you can do the necessary finishing with your own hands to give the surface absolute evenness and smoothness. Regardless of what material is chosen for the topcoat, you need to carefully eliminate the seams formed at the joints of the drywall sheets.

For this, a primer should be used. The primer is applied to the butt seams, then you need to wait until it dries completely. After that, using a putty, the surface is leveled, any seams, joints, holes from self-tapping screws are completely filled. After the putty has completely hardened, it is treated with a serpyanka, it is needed for a more durable gluing of problem areas.

Serpyanka tape, due to the porosity of the surface, improves the quality of drying of the further layer of putty. The areas where the serpyanka was glued are again covered with putty after the material has dried.

Sometimes, when performing installation work, problems may appear due to damage to parts of the drywall, for example, a gap has appeared in some place of the upper paper layer. This hole should be repaired so as not to spoil the aesthetic appearance of the finished coating. In the place of problematic irregularities, you can stick a serpyanka, after which dries, give the surface an even look with a putty.

At the stage of installing gypsum sheets, it is worth leaving the joints rounded. Plasterboard manufacturers have thought of this, so the edges of the sheets are rounded. It is much easier to seal the seams, which are round pits, rather than ditches, because of the more convenient filling with putty. After gluing the serpyanka and laying the putty, irregularities should not appear on the surface, their level should strictly correspond to the level of drywall, the edges of which are narrowed in thickness for processing the seams with finishing materials.

Special attention should be paid to the seams formed at the joints of drywall sheets that you cut off during the work. The ends of such sheets will have the usual thickness, if you stick a serpentine without special processing, then a small tubercle will appear at the seam site. To avoid this situation, you should chamfer the end of the sheet.

In other words, you need to cut the drywall sheet at an angle of 45 degrees in those places where it had to be cut to fit the ceiling. To do this, you can use a construction knife or a special plane. Then small recesses will appear at the joints, which can be easily filled with serpyanka, putty to the level of drywall. After the rough layer has dried, the final putty can be applied.

Preparation for the next stage is complete, you can proceed to the decorative finish. Now you can start painting the surface, pasting it with wallpaper, facing with decorative tiles, panels.

Manufacturers

Today, many companies are engaged in the production of materials for creating false ceilings. Some of the leading manufacturers of ceiling tiles are Armstrong, Selotex, Saint-Gobain, Cesal, Albes. Products from different companies are characterized by different properties.

Ceiling slabs "Armstrong", "Selotex", "Saint-Gobain" are made using mineral fiber and cellulose, so they are quite durable. But such ceilings can deform after impact, they need to be installed very carefully. Materials for the "Saint-Gobain" ceiling are softer, they are quite resistant to external influences. Soft ceilings are easier to transport and install, they are not prone to deformation.

The color scheme and texture of materials varies widely, companies present a large assortment so that everyone can choose the best option for decorating their premises. White is considered a classic option; it is often used to decorate false ceilings in offices.

Manufacturing companies produce ceiling tiles with figured elements, roughness. Such ceilings can be emphasized favorably by using the right lighting. Statistics show that the majority of buyers choose the classic white color, so the majority of manufacturers produce white materials.

It should be noted that such surfaces can be painted, giving them other shades.

Trying to satisfy the needs of all buyers, manufacturers produce different groups of materials that differ in functionality, quality and price. Large companies divide products into groups, giving recommendations on the area of destination.

For example, the well-known company Armstrong produces suspended ceiling materials in four main directions, each of which has an additional classification (smoothness, color, type of pattern, etc.).

Their products are divided into the following categories:

- "Basis";

- "Prima";

- "Functional";

- "Exclusive / Design".

Each of these groups has its own characteristics. The Basis group is considered the cheapest and simplest. These ceilings are made of simple materials and are not resistant to water. Such plates should not be hung in rooms with high humidity in order to avoid the formation of swelling on the ceiling, sagging.

Prima Group is designed for the climate of Central and Eastern Europe, these products tolerate high humidity well, retaining their original shape. They are a little more expensive than the basic ones, but nevertheless they are in great demand.

The group "Functional ceilings" is designed for installation in places with certain conditions, they have additional properties. For example, improved sound insulation properties due to the presence of microperforation or looseness of the structure. Also, special hygienic ceilings are produced, which can be installed in hospitals, child care facilities. Such models are distinguished by the presence of a special vinyl film that kills bacteria well.

Functional models also include models with increased moisture resistance, capable of absorbing moisture without losing their properties. Naturally, such materials are significantly more expensive than conventional ones.

The "Designers" group represents elite models developed by designers. They are of high quality and unique appearance.

Tips & Tricks

Installation of a suspended ceiling covering and its decorative finishing does not require certain skills; anyone can do it. These procedures are of medium complexity; accuracy and precision are important when performing work.

If you follow a few tips and tricks, you can greatly simplify your work and spend a minimum amount of time on creating and installing the ceiling:

- Choose quality materials. It is better to pay a little more than to start working again soon. Do not forget that such a structure is a durable, high-quality ceiling can serve for many years without reconstruction. It doesn't have to be cleaned every month.

- When counting the number of materials, you can use special programs on the Internet. You will significantly reduce your calculation time by using correctly measured ceiling lengths and widths.

- Before starting the installation, be sure to sketch out an accurate layout diagram.

- Take the preparation stage seriously so that you do not have to interrupt in the process of searching for materials or re-measurements. As they say, measure seven times - cut one.

- Do not rush to install drywall, let it lie horizontally for a while.

- To ensure sound insulation, it is worth using mineral wool.

- To prevent the loss of drywall properties, work with it in dry rooms.

Beautiful examples in the interior

The glossy stretch ceiling looks very stylish. It adds sparkle and chic to the room.

Satin ceiling coverings are distinguished by their originality. Come up with a fun design and start bringing it to life.

Multilevel stretch ceiling has long been a leader. You can create various designs with your own hands.

You can learn how to install the Armstrong suspended ceiling from the video below.

The comment was sent successfully.