Subtleties of Armstrong ceiling installation

Armstrong's tile ceiling is the most popular of the suspended systems. It is appreciated both in offices and in private apartments for many advantages, but it also has disadvantages. Below we will discuss all the subtleties of installing the Armstrong ceiling and give advice and recommendations for the use of this coating.

System features

The exact name of this type of coating is a tiled-cellular suspended ceiling. In our country, it is traditionally called Armstrong after the American manufacturing company. It was this company that, more than 150 years ago, began to produce, among many other building materials, natural fiber boards. Similar slabs are used today for Armstrong type ceilings. Although the device and technologies for installing such suspension systems have changed somewhat, the name remained as a common name.

Armstrong Tile Cell Ceilings are metal profile framing systems, suspensions, which are attached to the concrete base and mineral slabs, which are directly covered. The material for them is obtained from mineral wool with the addition of polymers, starch, latex and cellulose. The color of the slabs is predominantly white, but decorative coatings may have other colors. The frame parts are made of light metals: aluminum and stainless steel.

The mass of one mineral slab can be from 1 to 3 kg, the load per 1 sq. m is obtained from 2.7 to 8 kg. Products are predominantly white in color, they are rather fragile, exposed to moisture and high temperatures, therefore they are stored in reliable moisture-proof packaging. Such plates are cut with an ordinary painting knife. There are also more durable options made on the basis of latex and plastic, these require a harder tool for processing.

The benefits of Armstrong ceiling coverings are as follows:

- lightness of the whole structure and ease of installation;

- the ability to hide all the irregularities and defects in the ceiling;

- safety and environmental friendliness of the material;

- the possibility of easy replacement of plates with defects;

- good noise protection.

False ceilings, after installation, form voids in which electrical cables and other communications are usually hidden. If repair or installation of new wiring is required, then it is easy to get to it by removing a few plates, then they are simply put in place.

Ceilings of this type have their disadvantages:

- since they are installed at some distance from the ceiling, they take the height away from the room; it is not recommended to install the Armstrong system in rooms that are too low;

- mineral slabs are quite fragile, they are afraid of water, so it is better not to mount them in rooms with high humidity;

- Armstrong ceilings are temperature sensitive.

Usually, based on these disadvantages, certain places are chosen where Armstrong ceilings are installed. The leaders here are offices, institutions, corridors in various buildings. But often the owners of apartments during repairs make similar coatings on their own, most often in the hallways. In rooms where there may be high humidity, for example, in kitchens, the problem is also easily solved - special types of Armstrong coatings are installed: hygienic with protection from steam, grease adhesion and functional, moisture resistant.

How to calculate the amount of materials?

In order to calculate the amount of materials for the installation of Armstrong suspended ceilings, in general, you need to know what parts they are assembled from.

For installation, you need standard products with dimensions:

- mineral slab - dimensions 600x600 mm - this is the European standard, there is also an American version of 610x610 mm, but it practically does not occur in our country;

- corner profiles for walls - length 3 m;

- main guides - length 3.7 m;

- cross guides 1.2 m;

- transverse guides 0.6 m;

- height-adjustable hangers for fixing to the ceiling.

Next, we calculate the area of the room and its perimeter. It is worth noting that it is necessary to take into account possible floors, columns, and other internal superstructures.

Based on the area (S) and perimeter (P), the number of required elements is calculated using the formulas:

- mineral slab - 2.78xS;

- corner profiles for walls - P / 3;

- main guides - 0.23xS;

- transverse guides - 1.4xS;

- number of suspensions - 0.7xS.

You can also calculate the number of materials for installing ceilings around the area and perimeter of a room using the numerous tables and online calculators available on construction sites.

In these calculations, the number of whole parts is rounded up. But you need to understand that only with a visual picture you can imagine how it is actually more convenient and more beautiful to cut slabs and profiles in the room. So, for example, about 2.78 pieces of standard Armstrong boards are needed per 1 m2, rounding up. But it is clear that in practice they will be trimmed with maximum savings in order to use as little trimming as possible. Therefore, it is best to calculate the norms of materials using a drawing with a lattice of the future frame.

Additional elements

As additional elements to the Armstrong ceiling frame, fasteners are used, on which suspensions are fixed to the concrete floor. For them, an ordinary screw with a dowel or a collet can be taken. Other additional components are lamps. For a similar design, they can be standard, with dimensions of 600x600 mm and simply inserted into the frame instead of the usual plate. The number of lighting fixtures and the frequency of their insertion depends on the design and the desired level of lighting in the room.

Accessories for Armstrong ceilings can be patterned decorative tiles or squares with round cutouts in the middle for recessed spotlights.

Preparatory work

The next item on the Armstrong Ceiling Installation Flow Chart is surface preparation. This type of finish visually hides all the defects of the old ceiling, but it is not protected from mechanical damage. Therefore, first of all, it is necessary to remove the old coating - plaster or whitewash, which can peel off and fall on the mineral slabs. If the existing material is firmly attached to the ceiling, then you do not need to remove it.

If the ceiling is leaking, then it must be waterproofedbecause Armstrong ceiling slabs are afraid of moisture. Even if they are functional and moisture resistant, then this future ceiling will not save from large leaks. As a waterproofing material, you can use bitumen, waterproof polymer plaster or latex mastic. The first option is cheaper, the last two, although more expensive, are more effective and harmless to living quarters. Existing joints, cracks and crevices must be sealed with alabaster or plaster putty.

Armstrong ceiling construction technology allows for the placement of the frame at a distance of 15-25 cm from the floor slab. This means that thermal insulation can be placed in the free space. For this, various insulating materials are used: polystyrene, mineral wool, expanded polystyrene. They can be attached to the old ceiling on an adhesive base, screws, or use a frame made of a rigid metal profile, wooden slats. Also at this stage, the necessary electrical wiring is laid.

The Armstrong installation instructions then include the markup. A line is drawn along the walls along which the corner profiles of the perimeter of the future structure will be attached.Marking can be done using a laser or regular level from the lowest corner in the room. The fixing points of the Euro hangers are marked on the ceiling. It will also be useful to draw all the lines along which the transverse and longitudinal guides will go. After that, you can proceed with the installation.

Mounting

Do-it-yourself installation of the Armstrong system is very easy, 10-15 sq. m of coverage can be installed in 1 day.

You will need the following tools for assembly:

- laser or bubble level;

- roulette;

- drill or perforator with a drill for concrete;

- Phillips screwdriver or screwdriver;

- scissors for metal or a grinder for cutting profiles;

- screws or anchor bolts.

Elements of such ceilings are good because they are universal, the details of any company are identical and represent a constructor of guides and adjustable hangers with the same fasteners. All profiles, except for the corner ones for walls, do not need self-tapping screws or screws, they are connected using their own fastening system. Therefore, to mount them, you do not need extra tools and materials.

Installation begins with fixing the corner guides around the perimeter. They must be fastened with shelves down so that the upper edge goes exactly along the line marked earlier. Self-tapping screws with dowels or anchor bolts are used, pitch 50 cm. In the corners, at the joints of the profiles, they are slightly cut and bent.

Then fastening nodes must be screwed into the old ceiling and all metal suspensions must be hung on them by the upper hinges. The layout of the fasteners should be such that the maximum distance between them does not exceed 1.2 m, and from any wall - 0.6 m.In places where heavier elements are located: lamps, fans, split systems, additional suspensions must be fixed, at some offset from the place of the future device ...

Then you need to assemble the main guides, which are attached to the hooks of the hangers in special holes and hung on the shelves of the corner profiles along the perimeter. If the length of one guide is not enough for the room, then you can build it up from two identical ones. A lock at the end of the rail is used as a connector. After collecting all the profiles, they are adjusted horizontally using a butterfly clip on each hanger.

Next, you need to collect the longitudinal and transverse slats. All of them have standard fasteners that fit into the slots on the side of the rails. After complete installation of the frame, its horizontal level is checked again for reliability.

Before installing mineral slabs, you must first install lights and other built-in elements. This makes it easier to pull the necessary wires and ventilation hoses through the free cells. When all electrical appliances are in place and connected, they begin to fix the plates themselves.

Deaf mineral slabs are inserted into the cell diagonally, lifting and turning must be carefully laid on the profiles. You should not put too much pressure on them from below, they should fit without effort.

During subsequent repairs, installation of new lamps, fans, laying cables or decorative panels, the laid plates are simply easily removed from the cells, after work they are also placed in their place.

Tips & Tricks

It is worth remembering that different options for finishing materials can be used for different institutions. For entertainment venues, schools, clubs, cinemas, it is worth choosing Armstrong acoustic ceilings with increased sound insulation. And for canteens, cafes and restaurants, hygienic plates are specially made from stain-resistant grease and material. Moisture resistant elements containing latex are installed in swimming pools, saunas, laundries.

A separate type of Armstrong ceilings are decorative slabs. They usually do not possess any useful physical properties, as described above, but they serve an aesthetic function. Some of them are great options for design art.There are mineral slabs with a volumetric pattern embossed on the surface, with various textures, glossy or matt reflective light, under the texture of different types of wood. So you can show your imagination when renovating.

Depending on the height to which the Armstrong ceiling frame is lowered, it is necessary to choose the right Euro hanger. Different companies offer several options: standard adjustable from 120 to 150 mm, shortened from 75 mm and extended to 500 mm. If you only need a fine finish of a flat ceiling without drops, then a short option is enough. And if, for example, it is necessary to hide ventilation pipes under a suspended ceiling, then it is better to purchase long mounts that can lower the frame to a sufficient level.

In wide rooms, the main cross rails can be easily extended using the end locks. It is also easy to cut them to the desired length. Suitable corner metal profiles can be used as perimeter frames.

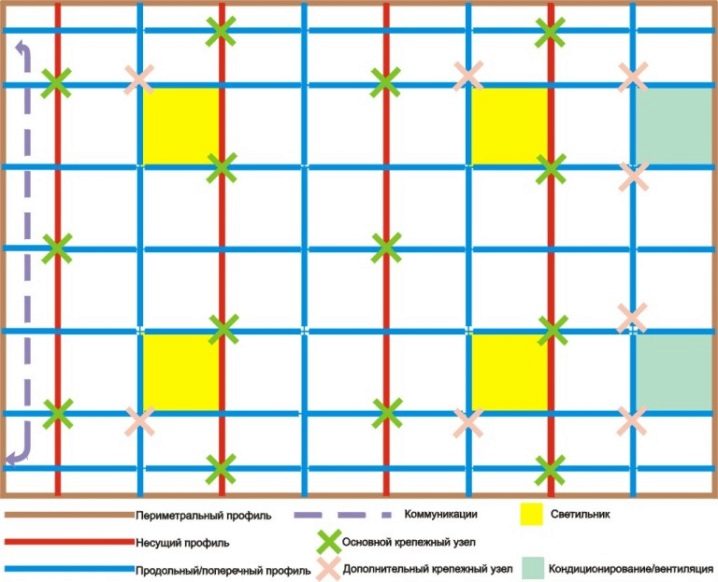

For ease of subsequent assembly, it is best to pre-create a diagram containing perimeter, bearing, transverse and longitudinal profiles, laying of communications, location of ventilation, lamps and blank slabs, main and additional fasteners. Mark different elements with different colors. As a result, from the picture, you can immediately easily calculate the consumption of all materials and the sequence of their installation.

When replacing, repairing Armstrong ceilings, the rules for dismantling are as follows: first, blank plates are removed, then disconnected from the power supply and lamps and other built-in appliances are removed. Then it is necessary to remove the longitudinal and transverse profiles and last of all the supporting rails. After that, the hangers with hooks and corner profiles are dismantled.

The width of the metal profiles of Armstrong ceiling frames can be 1.5 or 2.4 cm. In order to securely fix the mineral slabs on them, you need to choose the right type of edge.

Currently there are 3 types:

- Boards with a Board type edge are versatile and fit reliably on any profile.

- Tegulars with stepped edges can only be attached to 2.4 cm wide rails.

- Microlook stepped-edged slabs fit onto thin 1.5 cm profiles.

The standard size of Armstrong ceiling tiles is 600x600 mm, previously 1200x600 varieties were produced, but they have not proven themselves in terms of safety and the possibility of a collapse of the coating, therefore they are not used now. In the USA, the standard for plates 610x610 mm is used, it is rarely found in Europe, but it is still worthwhile to carefully study the size markings when buying, so as not to purchase the American version, which is not combined with the metal fastening system.

The Armstrong Ceiling Installation Workshop is presented in the following video.

The comment was sent successfully.