Choosing an electric jointer

A rich arsenal of modern tools is used in carpentry. This includes, among other things manual and stationary electrified jointers. It is worth noting that the correct selection of the tool allows you to significantly simplify the performance of all work, making this process as comfortable as possible.

Peculiarities

Initially, it should be noted that manual and stationary electric jointers from the point of view of the device are in many ways similar to each other. The operation of such equipment is based on the transmission of torque from the power unit (electric motor) to the knife drum.

During rotation, the tool head moves in a vertical plane. The electric planer is equipped with several types of knives for wood. By the way, this is the main difference between the electric jointer and its mechanical "ancestor". This means that the processing is carried out by rotary motion, not translational.

It is important to take into account that the number of knives may differ for different models of power tools, which fluctuates, as a rule, from 1 to 3.

Professional modifications of this equipment, which are popular and demanded by craftsmen, have a number of important features. These include:

- high weight and increased downforce;

- maximum precision when processing wood;

- increased productivity;

- the ability to quickly replace cutting elements.

Due to the high operational performance of the electrofuge, today it is widely and successfully used both in domestic conditions and on an industrial scale. At the same time, one of the most significant disadvantages of the equipment is its rather high cost.

Device and principle of operation

Manual and stationary (table) planers have the same design features and principle of operation. The torque is transmitted from the motor to the knife element by means of a reduction gear. As already noted, as a result of rotation, the head with replaceable blades begins to move vertically.

The delivery set of jointers includes knives for processing materials with different hardness values. One of the important features of electrified models of carpentry tools is control system... It is on her that the safety of operation of a manual electric fuger directly depends. On the body of the device are located two buttons responsible for starting the device.

It is important to take into account that the electric motor will only start when both controls are pressed simultaneously.

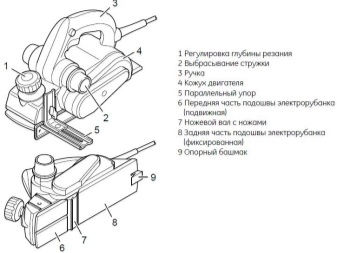

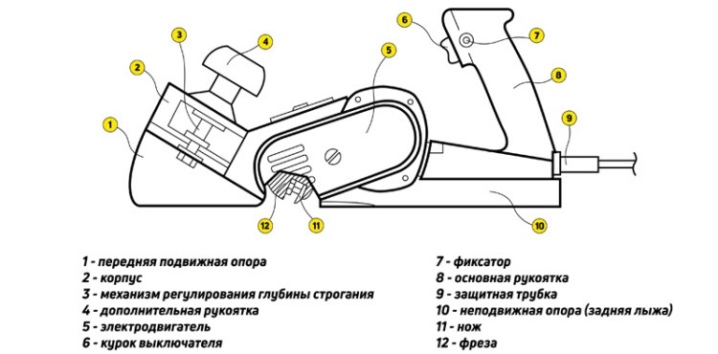

And also on the body of the manual jointer there are other details.

- A special socket that allows you to connect a conventional vacuum cleaner for efficient chip removal. Most often, this element is located on the right side. Some models provide the ability to change the position of the socket.

- Persistent handle.

- Control buttons.

- The planing depth adjuster in the form of a screw, the position of which is changed manually.

- Side stop, responsible for adjusting the width of the surface of the treated wood.

- The protective cover is hinged.

- The jointer sole is made of heavy-plate, brushed aluminum.

In addition to all of the above, on the equipment case you can locate the battery connector. An 18-volt battery can be connected.Naturally, there is a cable for connecting the instrument to a household power supply.

Species overview

All models of the considered equipment available today are divided into manual and stationary... The former are designed for processing relatively small workpieces. One of the key design features of handheld electric planers is the presence of a fastener for installing the tool on the workbench.

Stationary models are usually are operated in the conditions of carpentry workshops and furniture enterprises... Naturally, this equipment belongs to the professional category.

For household purposes, a hand tool rigidly fixed to a workbench will be sufficient.

Manual

It is no secret that the performance of work with a mechanical jointer requires significant physical effort. Based on this, the demand for electric hand-held models is growing at a record pace. As already noted, such a tool, when installed on a workbench or table, essentially turns into a small stationary woodworking machine.

Despite the fact that the manual electric planer is a carpentry tool mainly for household use, with a competent approach, it allows you to process solid volumes of wood. Moreover, the list of obvious advantages of such models includes their mobility... An equally significant point is due to the lower cost of equipment compared to stationary modifications.

In accordance with numerous reviews, it is more convenient for many craftsmen to work with a hand tool. This is due to its increased maneuverability, relatively low weight and ergonomics.

Stationary

Equipment belonging to this category is significantly more expensive than manual models. The cost of stationary electrofugans, which are professional carpentry tools, starts at 12 thousand Russian rubles. Naturally, the functionality and operational properties of such devices differ significantly from their manual counterparts.

The stationary electric jointer is designed to perform a large number of manipulations.

- Planing lumber and large boards.

- Facing workpieces at any angle.

- Selection of through grooves and shaped elements, that is, operations that are extremely difficult to perform with a hand tool.

- High-quality processing of the array, the width and length of which are up to 650 and 3000 mm, respectively. It is important to take into account that the thickness of the workpiece must be at least 12 mm.

- Processing of especially durable wood species, which include, for example, hornbeam and oak. It should be noted that, taking into account such possibilities, stationary jointers have a reduced number of revolutions of the cutter head. The increased productivity of the workpiece processing process is ensured by the corresponding power up to 6 kW.

Among other things, the considered equipment samples have the following technological features:

- an increased number of cutting elements with a large diameter;

- equipping a stationary guide fence;

- the ability to adjust the height of the table;

- the presence of protective hinged covers;

- the planing depth is determined by a special mechanism that controls the extension of the knife head axis.

Shaft with knives located in radial rolling bearings and perpendicular to the table axis. In a similar way, potential distortions of the workpiece to be processed are compensated for in the process of its planing. This, in turn, ensures an even distribution of force between the knives used. Another design feature is two-piece bed-mounted table. At the same time, its rear part is stationary and is located on the axis of the knife shaft, and the front part is movable, taking into account the thickness of the removed shavings.

Which one is better to choose?

The answer to the question, what exactly is the difference between a professional stationary jointer and manual tool models, remains relevant. In parallel, potential buyers are interested in the performance indicators of these two categories of devices. But most often the questions relate to which model to choose in a given situation.

The list of the most important includes some key selection criteria.

- The power of the jointer, which is the main characteristic of any power tool, directly affecting its performance. As a rule, this parameter of household appliances varies in the range of 400-1000 W, and the power of stationary machines reaches 2200 W.

- The number of revolutions, which must be at least 10,000 per minute.

- Processing width of the workpiece in one pass.

- Planing depth.

- Equipment weight. In situations with manual models of electric planers, this figure varies from 2 to 5 kg. Heavier specimens, as a rule, belong to the professional category.

It is the technical characteristics that determine the purpose of the tool. However, it is recommended to take into account the ergonomics of the models in question when choosing. The shape of the jointer body and the list of additional elements and functions will be no less important.

Operating rules

To perform work with a manual jointer, you will need appropriate knowledge and practical skills. First of all, it is worth focusing on the preparatory stage, which includes a number of manipulations.

- Tool setting with setting the required planing depth and working width. Household electric planers allow you to process planes with a width of 50 to 110 mm. It is important to take into account that this parameter is determined by the power of the equipment. The immersion depth of the knives depends on the characteristics of the wood being processed.

- Checking the number of revolutions of the power unit. By the way, there is a misconception that the performance of a tool is directly proportional to its speed. However, in practice, as the number of revolutions increases, the torque and force decrease, which negatively affects the quality of the processing of hardwoods.

- Determination of the feed rate. During the operation of jointers, this parameter can be up to 30 mm / s at a planing depth of up to 1.5 mm. If the latter is higher than the specified value, then the practical feed varies in the range of 10-20 mm / s.

In addition to all of the above, at the preparatory stage it will be required secure the workpiece to the workbench as securely as possible... Experienced craftsmen advise starting processing from the ends and at a minimum depth of penetration of the knives. The feed and depth increase if there are no defects on the surface after the first pass. Changing them is allowed only after turning off the tool and completely stopping the drum. And also a prerequisite is inspection of the treated surface in order to detect the possible presence of nails and other foreign objects.

To ensure maximum straightness of the jointer movement, it is recommended to make the markings with crayons or a construction pencil. This also determines the uniformity of the planing. In places with preserved marking lines, the processing depth will be shallower.

When using stationary planing machines, the workpiece to be processed is fed to the shaft with knives manually or automatically using a suitable device. A rather rich arsenal of special software is stored in the memory block of the equipment. It adjusts the parameters based on the characteristics of the wood. By the way, professional models are capable of processing several planes at the same time.

Before setting up a stationary electrofugan, it is required to lower all parts of its working surface. After that, the required number of blades is installed on the shaft, observing parallelism.At the final stage, it is necessary to set the working surfaces and guides, then check the machine at idle speed.

To learn how to make a planer from an Interskol 110 electric planer, see the next video.

The comment was sent successfully.