All about joinery workbenches

In the workshop of a professional woodworker, a carpenter's workbench is an invariable and important attribute.... This device, necessary for work, makes it possible to conveniently and ergonomically equip the workspace, regardless of which tool - manual or electromechanical - they plan to use.

A cycle of processing wood products is performed on the carpentry table. The design features and various devices available on the workbench make it possible to process wooden blanks in any desired plane. In addition to assembling products, you can carry out their finishing treatment using various compositions of paint and varnish compositions.

Peculiarities

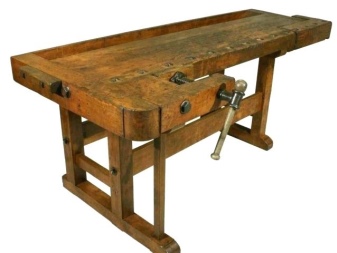

The joiner's workbench is a stable and reliable device in the form of a work table, the purpose of which is to perform carpentry work.

The most important requirement for such equipment is its durability and ease of use.

Any carpentry workbench is equipped with a set of additional devices that are necessary to fix parts during their processing.

Workbench parameters depend on what mass and dimensions are assumed for the processed wooden blanks, as well as on the dimensions and availability of free space in the room. In addition to full-size designs, there are also compact options.that can be used for home or cottage use.

The complex of works that are performed on a carpentry workbench is carried out using electric or manual type of tool. The load on the workbench can be very significant, so it made with the use of strong and thick timber from extra strong wood species: beech, oak, hornbeam.

A worktop surface made from soft wood, for example, spruce, pine or linden, will quickly deteriorate, especially with intensive use of such equipment, which will entail additional costs for periodic coverage renewals.

The carpenter's workbench has several elements that are fundamental to this design: base, table top and additional fasteners. Table top must be strong, and you can check this like this: put a few small objects on the workbench, and then hit the surface of the workbench with a carpenter's hammer - objects lying on the tabletop should not jump during this action.

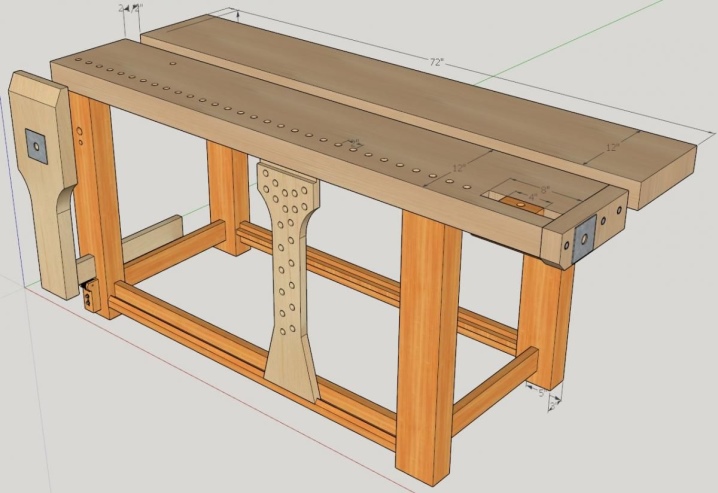

Traditionally, a workbench tabletop is made so that it does not have excessive elasticity. - for this, several wooden blocks are glued together in an upright position, while the total thickness should be from 6 to 8 cm. Sometimes the tabletop is made of two panels, between which a longitudinal gap is left. Such a modification makes it possible to process parts and engage in sawing them without resting on the edge of the workbench, and fixing the workpiece due to its support on the tabletop with its entire area.

Base for carpentry workbench looks like two frame supports that are connected with two drawers. The supporting part must have good rigidity and strength, its constituent elements fit into each other according to the principle of a thorn-groove connection, which are held together by wood glue. The drawers, in turn, pass through the through holes and are fixed with driven wedges - occasionally wedges need to be added, since the wood shrinks and loses its original volume,and also the table is loose from heavy and regular loads.

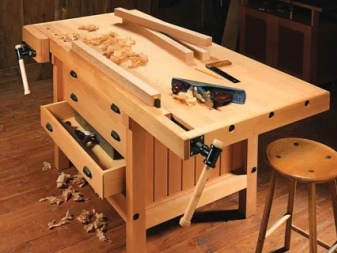

In terms of additional devices, carpentry tables differ from locksmith models, which lies in the fact that the pressing parts are not made of steel, but of wood. Metal vices are not suitable for processing wooden blanks, as they leave dents on the surface of the product.

Usually the workbench is equipped with a pair of vices positioned on the surface of the worktop. The various stops are inserted into the corresponding slots on the table and are used only when necessary, while the rest of the time they are stored in a separate box. The tool tray is good because nothing is lost during work and does not fall off the workbench.

Types and their structure

Professional wooden workbench Is a versatile and multifunctional working tool for the joiner and carpenter. The options for the design of the carpentry desktop can be different and depend on the functionality of those tasks that are determined by the technological processes of processing blanks.

Stationary

it classic carpentry look, which is constantly in the same room and does not imply any movement during its use. A simple workbench makes it possible to work with parts of various sizes and weights. As a rule, this is a massive and durable structure, consisting of the main parts and having additional equipment - a screw, clamps, stops that secure the parts.

A stationary workbench can be completed at the discretion of the master. For example, a jigsaw, a milling machine, an emery, a drilling device can be installed in it. Such a wagon, 4 in 1, is convenient because the master has everything he needs at hand, which means that his productivity increases.

The table top at stationary workbenches is made type-setting or made of solid wood. It is not recommended to use chipboards for the workbench, as such a coating will be short-lived. In the opinion of professionals, the length of the tabletop is most convenient in the size of 2 m, and its width will be 70 cm. This size makes it possible to conveniently process both large and small workpieces.

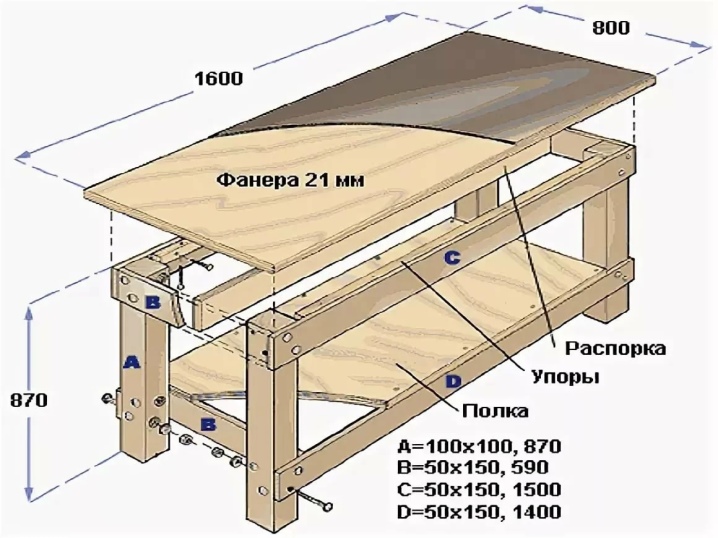

For the frame of the structure, a bar is used, the cross-section of which must be at least 10x10 cm... The thickness of the collets should have a cross section of 5-6 cm or more. The joints are made with a spike or dowel joint, and also use bolts and screws.

To install the table stop, through holes are made in the table, and they are placed so that the adjacent vice can make at least half of the stroke.

Stops just like the jaws of the vise, they are made of solid wood, the metal stop is not used, since it will deform the workpieces, leaving dents on them.

Mobile

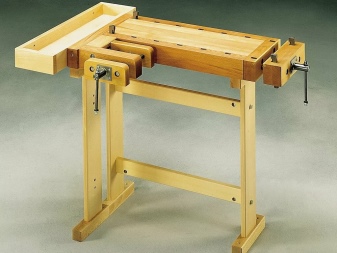

There is also a compact, portable type of joinery workbench. It is used if there is not enough free space for work. The length of a mobile workbench is usually no more than 1 m, and the width can be up to 80 cm. Such dimensions allow you to transfer the workbench from place to place, its weight is on average 25-30 kg.

The compact device is convenient because it can be used for the purpose of processing small parts, perform various repairs, do wood carving.

The mobile joiner's workbench is convenient in the home, garage, summer cottage and even on the street. As a rule, compact devices have a folding mechanism, which allows you to store such a workbench even on a balcony.

Prefabricated

This type of joinery consists of separate modules, which can be replaced if necessary, since the collapsible construction of the workbench has bolted connections. Prefabricated models are used to perform various methods of processing workpieces, and they are also indispensable where the free space is limited.

Most often, prefabricated joinery workbenches have removable tabletops and a frame-base equipped with a folding mechanism. The workbench can become a workplace for one or two people at once. The construction of the workbench allows you to transfer it over certain distances or move it within the workshop.

For prefabricated models, countertops are often made on special hinges, thanks to which it can recline, and frame legs at the same time they will fold under the folding part. Prefabricated workbenches are used to work with workpieces of small size and weight. The supporting frame of such structures is much smaller in size than that of stationary massive counterparts. The worktop for a prefabricated workbench can be made not only from solid wood, but also from plywood or chipboard, since such workbenches are not expected to be heavily loaded.

Dimensions (edit)

The dimensions of the carpentry workbench will depend on how many people will work at it at the same time. The model can be executed in mini format, easy to carry, or have standard dimensions for stationary use. The device should be convenient for the person who will work behind it, therefore the most popular models are with tabletop height adjustment. Besides, the dimensions of the workbench also depend on the availability of free space in the room where it is planned to carry out woodworking work.

The most ergonomic workbenches are considered options taking into account all dimensions.

- Height from floor level... For the convenience of performing work and minimizing fatigue of the master, it is recommended to choose a distance from the floor to the tabletop of no more than 0.9 m.This parameter is suitable for most people with a height of 170-180 cm.In addition, it is necessary to take into account the installation location of the working machine - it must be attached to the device be convenient access and the ability to make free movements in the process.

- Lenght and width. Experts consider the most convenient width to be 0.8 m, and the length of the workbench is most often chosen no more than 2 meters. If you yourself plan to create a workbench for yourself, then when developing a design, you should take into account not only the dimensions, but also take into account the size and number of additional trays, shelves, drawers.

- Additional accessories. For a woodworking workbench to be comfortable and multifunctional, you must equip it with at least two clamps for fixing wood parts. The location of the workpieces depends on whether a left-handed person will work at a workbench or a right-handed person. Usually, 1 clamp is installed on the right side of the table end, and the second clamp is located on the left, on the front of the table top. For left-handers, all clamps are reset in mirror order.

When choosing the dimensions of the countertop, it is important not to forget that part of the table space will be occupied by places for attaching hand or power tools, as well as sockets and electric lighting lamps.

How to choose?

Choosing a comfortable table for carpentry work in many ways depends on the preferences of the master himself. The dimensions and functional additions of the workbench models are determined range of tasks, what will be done when woodworking blanks.

The dimensions of the parts, their weight, the frequency of use of the workbench - all this plays a role in the selection of its version. In addition, there are also general standards that you can focus on when choosing:

- Determine which workbench you need for work - a stationary model or a portable one;

- the joiner's workbench must have such weight and dimensions that the structure is absolutely stable during operation;

- it is necessary to determine in advance what devices you will need in your work, what functional additions the workbench should have;

- when choosing a model, pay attention to its dimensions and compare them with the surface area on which you will install the workbench - will there be enough space to accommodate the equipment you have chosen;

- decide what maximum dimensions and weight the workpieces with which you have to work will have;

- If you need a compact workbench, determine if you have enough space to store it when folded, and if you can install it in the intended place to work when unfolded;

- the height of the workbench should be selected taking into account the height of the person who has to work behind it;

- When choosing the dimensions of the tabletop, consider where all additional devices will be placed so that the master can effortlessly reach with his hand to any tool.

To choose a convenient carpenter's workbench without overpaying for those extras that you do not need to work, carefully weigh the pros and cons of the models you like. Experts recommend selecting a workbench, mainly focusing on its purpose. If you want to do only woodworking work, then it makes sense to pay attention to carpentry workbench options.

And in the case when you also have to deal with metalworking, then it is most advisable to choose locksmith's workbench. For a home craftsman, a universal model is suitable that allows you to perform both types of work.

The same principle should be followed when choosing additional functional equipment for your workbench.

Choosing a joiner's workbench for work, pay attention to what material its countertop is made of. The wooden table is only suitable for working with wooden blanks. The metal sheathed worktop can also be used for working with metal parts. If you sheathe the surface of the table with linoleum, then such a workbench is suitable for working with small-sized workpieces, and the polypropylene coating will allow you to work with chemical components that are used, for example, when painting workpieces - these can be varnishes, paints, solvents.

A joiner's workbench for work can be bought ready-made, through specialized retail chains, or you can make it yourself. A do-it-yourself workbench will be convenient in that it can meet all the wishes of the master, and its cost, as a rule, is lower than that of factory models.

In the next video, you will learn about the main differences and advantages of classic joinery workbenches.

The comment was sent successfully.