All about CNC woodworking machines

CNC machines for wood - these are technical devices that operate using numerical control. If you call them robots, there will be no mistake, because it is, indeed, an automated robotic technology. And she greatly simplified life for those who are used to working with wood and achieve perfection in this.

general description

The main difference between CNC machines and machines without such control is that they can perform operations without the participation of an employee. That is, he, of course, first sets these operations, but then the machine “thinks” and does it itself. Such units are indispensable for modern automation. And everything to make the production profitable, the enterprises made a profit, the quality and speed of production remained competitive. So, a CNC woodworking machine is a serious hardware-software system capable of converting a block of raw materials into a part, so that it can then be used in a larger mechanism. This is the general principle of the technique.

And if you simplify everything, then a CNC machine is a computer-controlled technique. And the processing process depends on two important components, CAD and CAM. The former stands for Computer Aided Design and the latter stands for Automotive Manufacturing. The CAD wizard creates the design of the object in three dimensions, and this object must be made by the assembly. But the CAM program allows you to turn the virtual model, created at the first stage, into a real object.

Modern CNC machines impress with their high fidelity, they work quickly, which favorably affects delivery times. For a market that forces you to think about competitors all the time, this is very important.

What kind of machines are these - there are a huge number of them, this includes laser cutters, and milling cutters, and lathes, and water cutters, and plasmatrons, and engravers. Even a 3D printer can be included in this list, albeit conditionally, nevertheless, the differences in addictive and extractive production are significant. A CNC machine is a real robot, it works exactly like that: instructions are presented to it, and it analyzes them and, in fact, makes them.

The code is loaded, the operator of the machine passes the test (this is necessary to eliminate errors in the code). When debugging is complete, the program will enter the postprocessor, and it will transform it into more code, but already understandable by the machine. This is called a G-code. He is the manager who manages all the parameters of the operation, from coordination to the speed indicators of the tool.

Species overview

And now more specifically about what kind of machines, in general, there are. Just for a start, you can break it down into two large groups.

By design

They may be console and consoleless... Cantilever means the ability to move the table in two projections - longitudinal and transverse. Moreover, the milling unit remains immovable. But such samples cannot be called popular precisely in working with wood; they are more suitable for steel parts.

On consoleless woodworking machines, the cutter moves with a carriage, which includes transverse and longitudinal guides. And the same program block can be located vertically and horizontally.

By the way, the number blocks themselves can be:

- positional - the cutter is fixed on the surface of the part that is being processed to a clear position;

- contoured - this means that the working tool can move along a given trajectory;

- universal - this is a combination of the functionality of other options, some models also provide for the control of the position of the cutter.

By the type of control, machines are made with an open system and with a closed one. In the first case, the program instructions are sent to the control unit through the ATC. And then the unit will turn them into electrical impulses and send them to the servo amplifier. In such machines, alas, there is no feedback system, but it can check the accuracy and speed of the unit. On machines with a closed system, there is such feedback, and it monitors the actual performance and corrects discrepancies in the data if necessary.

By appointment

The nature of the work performed comes to the fore. Dimensions (mini-machine or large machine) are no longer so important, desktop or not, what matters is exactly what it is intended for. These are the types provided here.

- Milling machines. With their help, you can process body parts with high quality. And also perform deployment - cut and drill, bore threads, do different types of milling: both contour, and stepped, and flat.

- Laser... Designed for laser cutting, they outperform mechanical devices in many ways. The laser beam is very powerful and very accurate, and therefore the cutting or engraving contour is almost perfect. And the loss of material on such a machine is minimized. And the speed of work is enormous, because for a house it may be an expensive unit, but for a woodworking workshop, for production, it is better not to find it.

- Multifunctional... The name speaks for itself. They can do almost anything, perform the functionality of milling and boring machines, lathes and those that cut threads. And the main thing is that the same part goes through a machining cycle without moving from one machine to another. And this affects the accuracy of processing, and the speed, and the absence of errors (the so-called human factor).

- Turning... These are professional devices designed for machining parts in a rotary process. This is how conical, cylindrical and spherical blanks are created. The screw-cutting lathe subspecies of such machines are probably the most popular.

There is, for example, a machine-burner, respectively, for burning wood. And such devices can be purchased both for woodworking production and at home.

Popular manufacturers and models

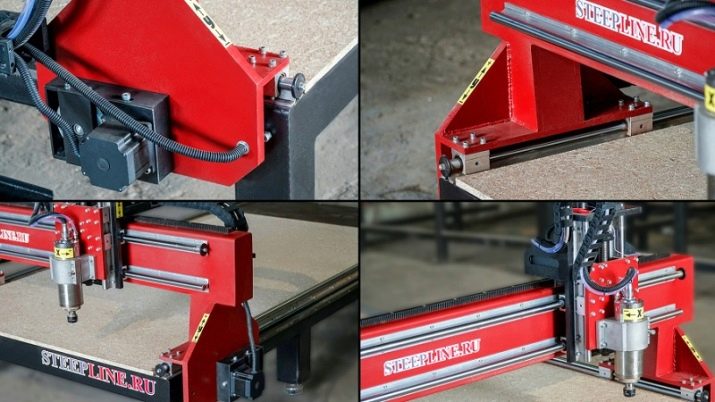

- This list will definitely include such machines as SteepLine - they are able to make complex wooden parts, and they are also ready to work for furniture production, for the manufacture of decorative items and architectural elements.

- An excellent choice for a rich CNC machine would be SolidCraft CNC 3040: produces 2D and 3D woodwork, creates amazing multidimensional carvings, is able to carve cliches, photo frames, words and individual letters. It is very convenient to use, ergonomic, it is not difficult to understand the device.

- The device will also be in the top of frequently recommended machines. JET - benchtop drilling machine with several functions.

You should also pay attention to the following brands: WoodTec, Artisman, Quick Dirtec, Beaver. If the brand is from China, you should not ignore it, many Western companies assemble products in China, and the level of production there is competitive.

Components

The basic kit always includes the chassis, rails, board, drivers, drives, work spindle and body kit. On his own, the master can assemble the bed, the portal, can connect the electronics and, finally, make the first start-up of the machine. It is quite possible to order some basic components from Chinese sites (the same vacuum cleaner) and assemble a dream car.

For example, the first machine, budgetary, but productive, can be a machine assembled from: guides (rails with carriages), drive screws, motors (for example, Nema 23) with couplings, a special driver connected to a board or a control panel.

What to consider when choosing?

To choose a machine means, first of all, take into account the technical characteristics of the unit. Such factors are worth paying attention to.

- Working speed, engine power - spindle speed 4000-8000 rpm is considered standard. But it all depends on the request - for example, for laser cutting in professional production, the speed is only needed high. This criterion also depends on the type of drive. In budget devices, stepper motors are usually supplied, and with an increase in speed, they sometimes skip a step, that is, the machine is no longer high-precision. But the servomotors are much more accurate, the error in their work is simply excluded.

- Working surface indicators... It is necessary to choose a work surface that will be slightly larger in size than the workpiece being processed. Plus a place to fix the clip. That is, this factor is determined by the size of the processing space.

- Power... If you take a machine with a weak spindle, cutting tough materials results in a drop in speed and productivity. And the deformation of the machine itself is not excluded. In modern small and medium-sized CNC machines, mechanical spindle switching is rare, but a motor with current speed regulation is much more common.

- Accuracy... For the described devices, the control criteria for accuracy are at least two dozen, or even all three. But the main ones are the axial positioning accuracy, as well as the repeat positioning accuracy (along one axis), as well as the roundness of the sample-sample.

- Control type... Control can be carried out using a computer or a specialized stand-alone rack. The good thing about a computer is that the operator can take a simulation program, and even graphically display the entire workflow on the display. A stand-alone rack is more common in large production, and it works efficiently due to better integration and stability (by connecting to the control board of the machine).

It is important to understand what level of maintenance the machine requires - whether the craftsmen can handle it, whether serious training is needed.

Machine capabilities

Manual labor is almost eliminated with the advent of such equipment. And high process speeds help the use of machines in production, which is designed for high rates of delivery of finished products. If we talk about home machines, they do an excellent job of engraving, burning, cutting on wood, and applying various patterns to it. But for burning, for example, the device must have a laser.

So, you can start small and come to the production of doors, small furniture or interior accessories, crafts and decor. You can do what is in active demand right now: things necessary for home furnishing - from elegant hangers and key holders to coffee tables and shelves for an antique kitchen. And also such machines help to create molded products - baseboards and even floorboards. They are actively used in the creation of advertising material, decorative images, numbers and letters. With their help, carved partitions, chess, souvenir dishes and much more are made.

Safety measures at work

The operator working at the machine undergoes a complete physical examination. He must also pass an examination for the possession of equipment, knowledge of instructions, safety precautions and much more. And this should be documented. The category assigned to the operator is indicated in a special certificate. What is important to remember:

- equipment drives are disconnected every time the product is removed or the workpiece is installed;

- drives are switched off and, if necessary, removal of shavings, tool change, measurements;

- shavings are never blown off by mouth, there are brushes / hooks for this;

- before starting work, the operator checks the reliability of the tool guard, grounding, operability, idling;

- do not put anything on vibrating surfaces during work;

- the drive is turned off if breakdowns are detected, if network failures are noticed, as well as during lubrication of the device and during a break.

Do not lubricate it, clean it from sawdust, measure parts, check the processing surface with your hand while the device is in operation.

CNC machines are modern technology with huge possibilities, which essentially offers everyone to have their own production site.... And to use it to serve your own tasks or commercialize the process is a matter of choice.

The comment was sent successfully.