Everything you need to know about whetstones

Sharpening stones, although they are used in the old fashioned way (that is, they are sharpened by hand), in many ways beat their electrical counterparts. If machines operating at high speeds can accidentally damage the product (not the speed and sharpening time), then with a sharpening stone such risks are minimized. And they are also compact, you can take them with you on a hike, fishing, etc. Yes, and a large selection, a huge number of options seduce the buyer, which means that this issue is worth understanding in more detail.

What it is?

A sharpening stone is a versatile tool that is needed for both maintenance and repair of knives and razors, as well as other devices with a cutting edge. This is an ideal product for sharpening, since the intensity of processing, the force of pressure is chosen by a person independently (in the same comparison with electric machines, this advantage has already been mentioned). The small dimensions of the whetstones are also a convenient condition for use. Everyone faces the need to sharpen a knife. Even the most high-quality knife needs to be sharpened sooner or later. And it is more convenient to do it manually from all sides - not everyone has a machine, but carrying it to where it is and where they can sharpen a knife is a troublesome business.

The peasants, who from time to time sharpened their scythes, used bars called "whetstones" for this. But those simple sharpening stones were not as comfortable as modern ones: they had to be soaked in water for a whole day before being used. Actually, that's where the name "water stone" comes from. Subsequently, the bars began to be produced, their marking was already used in the USSR. On such a bar there was a brand of the manufacturer, the type of product, its dimensions and accuracy class, grain size, technical characteristics and, of course, the standard.

Align, sharpen, polish, clean - the functions of the bar can be different.

Description of species

Today, the choice of sharpening devices is huge, because the materials used to create them are not limited to a couple of three names. Stones differ in grain size, in the presence of accessories in the set and in price. Large-scale production of stones is noted in the USA, Japan, and Russia. If we distinguish the main groups of sharpening stones, they will be as follows: natural, diamond, ceramic and abrasive.

Aquatic

Water stones have been known to many since childhood, although not everyone understands what it is and how it works. Well, such an instance is even interesting to use. It does not work very quickly, you cannot count on an express result, and besides, you still need to be able to handle it. Namely - calculate and control the uniformity of movements and pressure, carry out regular care for them. But the quality of metal processing will be the highest.

What is needed for such a sharpening: a massive plate of marble or glass, water, as well as a large amount of large skin (the latter must be waterproof). The skin is applied to a marble or glass plate, and the stone itself moves easily and smoothly over the skin dipped in water or under running water. The skin changes with wear. And the working stone plane is brought back to its original form.

This can be done exclusively with natural stone.If this stone is already noticeably worn out, if it has become thinner, but is still ready to serve, it can be glued to a block of beech (or other hard wood). The disadvantage of water stones is the lubrication required during work, as well as washing away metal dust and worn abrasives.

And the grindability of natural stones is a characteristic characteristic of them, alas, they are not necessarily grinded evenly.

Diamond

They can have different grain sizes, are available in all kinds of forms. Often they have standard mounts to make it easier to use them in sharpening devices. It is advisable to use lubricant when working with diamond stones: it can be a soapy solution or the same water. Lubrication just adds neatness to the job.

Imported diamond stone is a base made of plastic or metal, its working surface is equipped with a diamond pattern, which is applied using special binders. The pattern is either honeycomb or ring-shaped.

Such a bar is required to be cleaned of metal dust less often than water stone, but it also works more aggressively.

The main and undoubted advantage of a diamond stone is a high speed of work.... And it also has low wear, and you don't have to edit the work surface. Lubrication may or may not be used. But the tool also has a drawback: it can ruin the edge if used inadvertently. However, in the field, a diamond stone is considered to be an excellent fixture. After use, you must remember to wash it with any detergent composition.

Elbor stone is often considered as an analogue of a diamond bar.

Boron nitride is not much inferior in performance to the same diamond, and therefore the strength and durability of elbor bars are guaranteed.

Emery

Usually this term refers to grinding wheels for emery. Emery is also called an electric machine with grinding wheels. On such a machine, they usually either sharpen or grind. Abrasive wheels are sold in a wide range, and they are most often used precisely for the initial, rough processing. Emery circles are white and green, and have different grain sizes.

Natural

Natural stones are considered a classic instrument, traditional and ancient. The fact is that many natural minerals have such qualities that are sufficient to effectively sharpen an edge. One of the most famous representatives of this species is the Arkansas stone, its official name is novaculite. Naturally, he owes his household name to the state of Arkansas, that is, to his homeland.

Arkansas stone is composed of quartz crystals pressed by natural forces. Such a block is ideal for sharpening the blades, because it is easy for the sharp edges of quartz to remove the upper metal layer. It should be noted that such natural products cost a lot, which is explained by the rather limited number of deposits where stones are mined. And in order to work properly with this product, you still need to learn. That is, buying such a product for a beginner is not the most rational decision.

Turning craft can be learned from something simpler and cheaper.

It is also impossible to say that this is an ideal stone and without flaws. For all its uniqueness in operation, it requires a lot of oil. Japanese water stones also belong to natural models. They have a fine grain, that is, they are suitable for soft sharpening. The life of such a stone can be increased if you turn on the emery machine from time to time.

It is believed that Japanese stones were raised from the bottom of reservoirs, which is why they are called that. No, this natural tool refers to the first point, which describes the principle of the water stones. Stone plus water - that's where the name comes from, but Japanese is a connection with a deposit of such stones.

Ceramic

Refers to synthetic materials that also show convincing results. And the manufacturers who make such products know the weaknesses of natural materials and exclude the appearance of such characteristics in artificial ones. Synthetics are usually understood as ceramic stones. Usually these are simple samples for finishing knives, because working with them is time consuming, that is, for the initial removal of the metal layer, it is better to take something else. But what exactly is good about ceramic stone is that it is very difficult for them to spoil the edge of a cutting object - that is, the stone will be a good purchase for beginners.

They are usually made in the form of not very large blocks, which are compact and easy to carry. The cheapest and simplest models are made of artificial stones based on carbide chips or alumina chips.

However, the durability of these products is not particularly high.

Oil

When working with some stones, it is suggested to use oil. It retains ferrous substances more efficiently than water. A thin oil layer is the guarantor of the access of the abrasive material to the metal. If the stone itself is thin, then it will need a thinner liquid layer as well. Each stone has its own oil. Chips formed from metal must be contained in the oil liquid.

The main function of oil when sharpening a knife is to prevent clogging by metal particles... Organic and sunflower oil are excluded as they will salt the bar. When cleaning the knife, a special light oil is used, after which the bar is cleaned with a brush. Kitchen knives are usually treated with edible oils, a few drops are enough for optimal results. Folding appliances are treated with castor oil, it works well on steel.

Camellia oil is expensive, but it has an ideal acid-free composition. It is odorless and neutral. And for kitchen utensils, it's a great anti-rust option.

Some experts claim that the oil can be replaced with stearin or oleic acid.

Round

These are the grinding wheels described above. They are mainly used for power plants. They differ in diameter and material, color, purpose. There can be steel, fused alumina, etc. Another name for this device is an abrasive wheel. And yet, most often these are synthetic stones, because the machine produces too high revolutions.

A round stone can also be produced in small sizes, it looks like a cylinder with which knives are sharpened.

True, one should not expect high results from them, but such a round stone is quite sound as a tool for dressing.

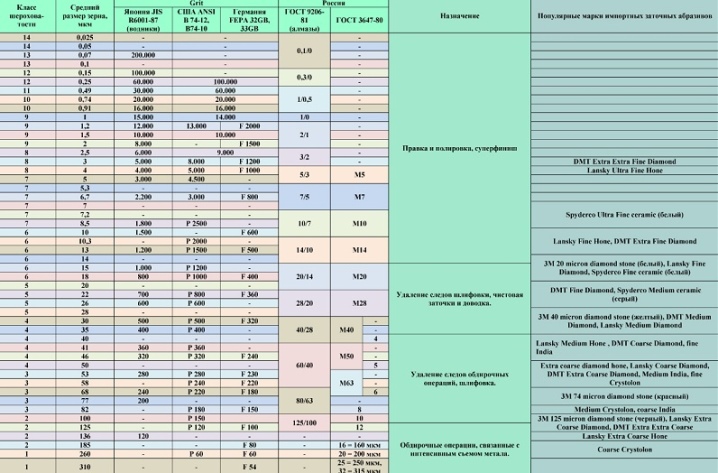

Grinding stone grain size

Even an amateur sharpening on stones is not something simple, always successful the first time. Those who have never used such abrasives are faced with the first problem in the form of "which stone to buy." And the grit ratio is also important in this choice. Grit is the gritness (sometimes they write "gritness"), this term of experts can often be heard in relation to this characteristic of stones. The value of this parameter determines how aggressively the stone will act on the metal.

Grit stands for a digital index of grain size, it is a technical parameter.

Description of the effect of graininess.

- Large grains inevitably leave deep grooves and chips on the metal surface, and no one wants this. Because ideally, after sharpening, a sharp and even edge should form, preferably mirror-like, without any visible defects. Therefore, coarse grains can only be used when working with blanks, for example, for a newly forged blade.

- Small grains - this is metal grinding and finishing polishing. It will take longer to tinker with such a stone, but all for the sake of an optimal result.

- Medium grain knives are sharpened if a slight bluntness of the blade is evident.

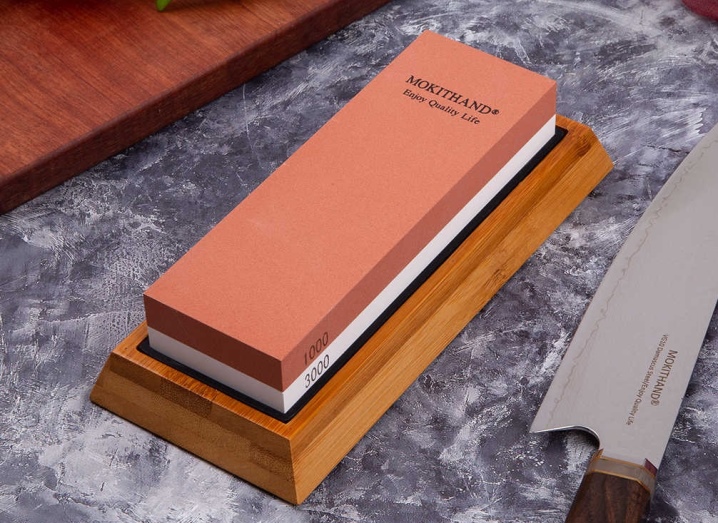

It turns out that, ideally, the set should include 3 double-sided stones: with the smallest grain, medium and large. The grit table with grades from 1 to 14 can also be a guide in the selection.

Popular manufacturers

The best producing countries of this product are the States, Russia, China and Japan. But it is interesting that many people are still looking for Soviet-made sharpening stone sets, and such vintage sets are highly regarded by experts. Although in some cases these stones are bought along with a touch of nostalgia, because modern manufacturers also offer high-quality goods.

Of the well-known brands with a good reputation, the following should be distinguished.

- "Petrograd" - models made of silicon carbide, various in surface hardness. Coarseness equal to Japanese standards.

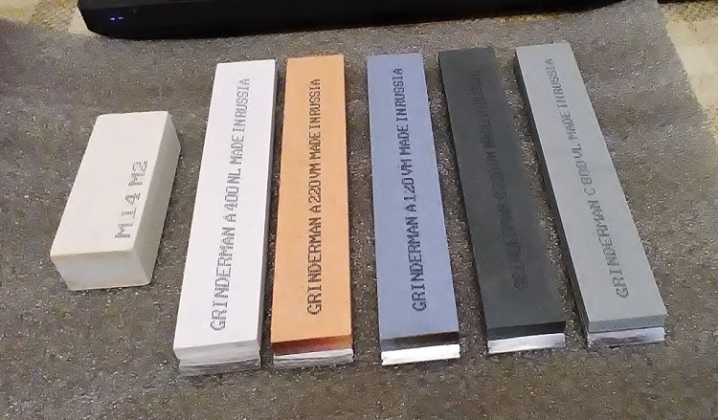

- "Grinderman" Is a St. Petersburg brand that not only produces a sharpening tool, but also provides its all-round service.

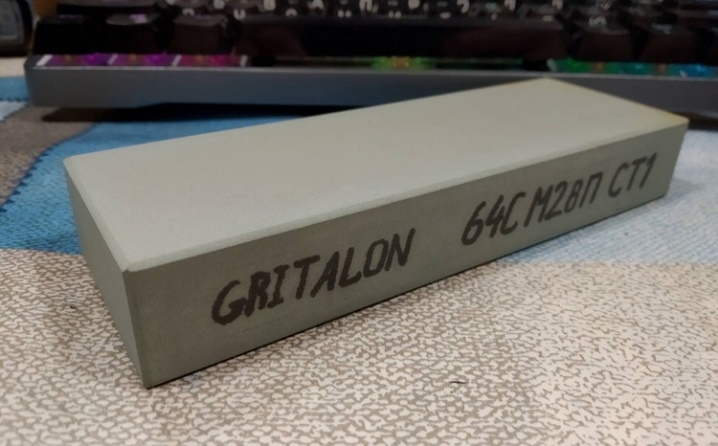

- "Gritalon" - the company presents an artificial abrasive product, it is used both for machine tools and for manual operation.

These are domestic manufacturers, with which Japanese brands enter the market - Samura, Yaxell, Suehiro, Yoshikin. The Japanese produce many excellent products with different functionalities, their water stones are considered to be of high quality, because their performance is the highest. They can only be compared with diamond samples.

Japanese grain standards are recognized by international organizations, they are used in the designation of most manufacturers... Famous Arkansas brands include Lansky, and the most famous Chinese manufacturer Ganzo... By the way, the Russian analogue is considered to be a white-talked stone.

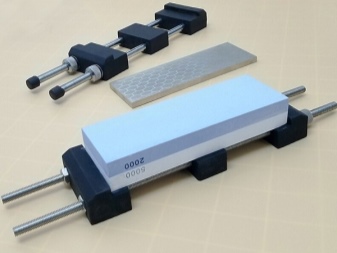

Accessories

Almost everyone who uses sharpening stones needs a coaster for them. You can buy a stand, or you can do it yourself. They are different, with an angular guide, the ability to adjust, etc. Very often these are plexiglass stands, as well as stainless steel screws. By weight, they are usually not very light, monolithic.

But, for example, you can make an adapter for a sharpener yourself from an ordinary bolt - there are several clear video instructions on how to make such a device in just 15 minutes. In the same way, you can make a sleeve for a grinding stone with your own hands, or rather, for a homemade grinding machine.

Nuances of choice

The main question of choice is what the stone is needed for, that is, it is necessary to proceed from the basic functionality of the product.

Tips for choosing.

- For kitchen knives, it is better to choose water stone, since it works faster, and you can edit the cutting element without problems. True, not all materials can come into contact with water, there is a risk of rust. If so, oil models will do, sharpening lasts longer, but this will not detract from the quality. Grit for kitchen knives is 1500, and, for example, 240 is an unacceptably low indicator, very rough for these purposes.

- You need to decide on the material of the abrasive. In everyday life, ceramics are increasingly used, in shape it will be a bar in the form of a boat. The most common option was a double-sided stone with a smooth and rough surface. But diamond bars for kitchen knives are considered a luxury.

- The size of the bar is also important, it should exceed the length of the blade by two or at least one and a half times.

Sharpening stones are needed not only for knives and other kitchen tools, they are also used for sharpening drill bits, for a screwdriver, grinder, meat grinder, cutters, chains. Usually, by marking, you can understand what this stone will serve.

How to use it correctly?

For the stone purchased for turning, there is usually an instruction - you need to get acquainted with it. Different types of sharpeners have different nuances of use. How to sharpen a knife with a stone?

- It makes sense to practice - hold the knives at an angle of 20 degrees relative to a flat surface.To find a suitable angle, you need to take the knife in front of you so that the edge of the blade looks exclusively down. Then the knife should be tilted halfway to the side, it will be at an angle of 45 degrees. Then again the knife must be tilted to the side and again halfway so that the blunt edge of the product only slightly rises above the table. This will be the angle of 20 degrees. But if the blade of the knife is very large or thick, the sharpening angle may be slightly larger.

Or if a stone with a larger grain size is used, the sharpening angle may, on the contrary, be smaller.

- If it is a stone for wet sharpening, it should be placed in water for 45 minutes. If the stone is dry, scratches on the surface of the knife are not excluded. If a stone is used that is made strictly for use with oil, it must not be soaked in water.

- A cloth should be moistened with water, wrung out and laid on the work surface. The sharpening stone is placed on top. What a rag is for: it prevents the stone from moving. This can be done with virtually any type of sharpener - with oil and diamond, too.

- If this is a double-sided sharpener of different grain sizes, it should be put up the rough side.

- If it is a stone that is intended for oil sharpening, you can either spray it with oil or pour oil directly onto it. Then the oil is rubbed into the stone with your fingers. He must be completely covered by it.

- Now, finally, the knife can be applied to the stone. With one hand, you should grip the handle of the knife, applying it to the stone at an angle of 20 degrees. The cutting edge should be facing away from the person. The fingertips of the other hand should be on the flat side of the cutting edge.

- Fingers located on the blade (or rather, their tips) will press on the stone and adjust the position of the blade during sharpening.

- One side of the blade should be drawn over the sharpener. The blade should slowly lead over the stone, smoothly displacing it in an arc. And the entire cutting edge of the knife must pass over the stone, from the beginning to the tip. And you need to sharpen until the knife becomes sharp.

- If the stone is water or oil, it must be moistened or oiled in the process to prevent drying out.

- Time to flip the knife to the other side... The action is repeated until the knife becomes sharp to the touch. Remember to be careful in this action.

- Then sharpening can be continued on a stone with a finer grain, this will bring about a high-quality polish. This should be done with two sides of the knife.

- Checking the sharpness of the knife is an important step. You need to wash it, wipe it, and then take a piece of paper and cut it with a freshly sharpened knife. A sharp knife will rip open the paper without any problem.

- The final stage consists of cleaning the knife and stone. Everything is done according to the manufacturer's instructions. If it is, for example, an oil stone, it must be periodically cleaned with a stiff brush, and also soaked in the same oil.

And so that the knives do not get dull often, they must be stored on a magnetic stand or use special covers.

Basic rules of care

Taking care of knives at home is easy, as well as stones for sharpening them. You need to focus on the quality characteristics of sharpeners. For example, water stones should only be stored in vinyl boxes that do not allow moisture to evaporate. But water can also hold them. A very important point: such a stone should not be allowed to freeze. It can burst and it will no longer be possible to use it for any profile.

All other sharpening stones should be kept in a place where dust accumulation is virtually impossible. It should be a closed box, cleaned from the inside from the same dust. Dust will clog the space between the abrasive elements and the stone will quickly reduce its effectiveness. Well, in order to protect the product from salting, it must be thoroughly cleaned after each cleaning procedure.

Whether a branded carborundum stone or any other product is used for sharpening, in order for it to serve for a long time, it must be protected from contact with other surfaces, cleaned in a timely manner and used according to its classification and functionality.

The comment was sent successfully.