All about thermal knives

Thermal knives for cutting polystyrene and fabric, for SIP panels and plastic, satin ribbons and films, models for soldering have firmly entered the everyday life of people engaged in creativity or construction and installation work. These tools are quite easy to learn, they can be desktop or manual, they significantly facilitate many technological operations that are put on stream in needlework. Hot knives perform simultaneous edging and cutting of material, requiring minimal physical effort during use.

Peculiarities

The thermal knife is a modern tool used for inline cutting of synthetic materials. The power tool is capable of processing the edge so that it does not crumble. A hot knife or thermal cutter heats up to a temperature of +600 degrees in a few seconds. The equipment is usually powered by wired, the instrument is connected to a 220 V.

The principle of operation of such devices is quite simple. The hot cutting part cuts it in contact with the material of synthetic origin, leaving no traces of burning or carbon deposits. One operation takes less than a second, which is very convenient when manufacturing a large number of the same type of workpieces. And also with the help of a thermal cutter, you can solder the materials folded in half along the edge with which they touch.

To obtain equal lengths, cardboard templates and blanks are used.

Views

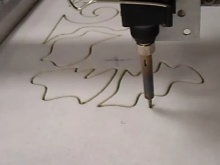

The thermal electric knife, depending on the features of its design, can be equipped with a thin blade or produced with a string. Models with a wide filament element are used in the construction and installation field. Some cutter options come with additional attachments. Industrial and professional models are capable of automatic cutting of materials - this is used in printing, printing flags, and other products. But the main classification includes only 2 types of instruments.

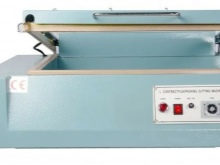

Tabletop

Stationary models are compact in size, easily fit on the surface of the countertop. The device looks like a power supply - it is a stand and a base, with 2 vertical metal rods and a string stretched between them. Its features include:

-

straight cutting only;

-

restriction on the width of the material;

-

high degree of electrical safety;

-

ease of use;

-

quick preparation for work;

-

versatility;

-

mobility.

Desktop thermal knives are most in demand today in the field of needlework. When working in the kanzashi technique, synthetic ribbons have to be cut into many separate parts. This is where the electric cutter becomes a necessary component to help speed up the process. At the same time, the tool is positioned steadily, heats up instantly, and consumes little energy.

Manual

This type of thermal tool outwardly resembles a glue gun with a replaceable tip block. It consists of a holder and a metal tubular heating element fixed in the holder-handle. The device has a power cord, the length of which largely determines the freedom of the operator.

A number of features of hand-held hot knives can be distinguished.

-

Compact dimensions. The tool is easy to store and fits comfortably in your hand.

-

Wide range of available operations. It is possible to cut fabric cuts of considerable width, to perform not only straight cutting, but also figured cutting.Such blades are suitable for working with foamiran, satin, and other synthetic materials.

-

Controlled pressure and velocity. The operator himself determines how quickly he will lead the hot knife, he can repeatedly pass problem areas with it.

-

The need to use a non-combustible base. The most commonly used glass or metal sheet. It is on it that blanks or cuts of fabrics are laid.

-

Options. Some models have a presser foot to make cutting fabric easier. And also hand-held devices have cooling blocks - coolers that help the blade cool down quickly and not overheat.

-

The ability to adjust the heating. Not all models have it. It will be useful if the master works with different types of materials.

Hand-made thermal knives are divided into household and professional. The first option has a minimum configuration, the heating temperature in it may not be automatically regulated. Professional models come with a large number of replacement attachments. They support cutting of materials of different sizes and thicknesses, have a built-in illumination of the working area.

Applications

The desire to purchase a thermal cutter arises both among lovers of needlework and among master builders. The scope of application of hot knives is as wide as possible. They are used for different materials.

-

For styrofoam. The material is prepared for modeling in floristry and other creative tasks.

-

For SIP panels. Here, precise cutting avoids crumbling of the material.

-

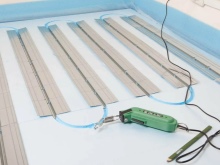

For penoplex. Thermal insulation materials of this type can also be easily cut with a hot blade. They are used mainly to create a warm floor.

-

For fabric. The tool is used for cutting and soldering parts made of satin, nylon tape and other synthetic materials.

-

For shrink wrap. This is how prints for T-shirts and other textiles are made.

-

For cutting plastic. It can be easily cut to size with a hot knife.

-

For foamiran. Here, thermal cutting helps to quickly cut through several layers of material, create curly elements. But it is important not to overheat foamiran - for it, the heating temperature of 400-600 degrees is quite high.

Numerous areas of application of thermal cutters are not limited to this. They successfully cope with cutting and bonding of almost any synthetic materials - from construction films for waterproofing, vapor barrier to special decorative bases in sheets.

Security measures

Working with thermal knives requires care and attention. Before starting work, the device should be inspected, check the integrity of the wire, perform a test turn-on. It is imperative to follow the instructions supplied by the manufacturer.

The blade or string of the thermal knife is heated to very high temperatures. Avoid direct skin contact with them. Even with short-term exposure, severe burns can occur. The heating element must cool completely before storing. Despite the fact that the tabletop models are quite stable, you should still provide for the presence of a stand made of non-combustible material in case they fall.

At the place of work with the device, it is also necessary to observe safety measures. It is necessary to isolate children and pets from contact with him. When cutting synthetic materials, combustion products can also be released into the atmosphere, especially if we are not talking about fabrics, but about building panels. It is important to ensure that there is sufficient air flow to the room or to move the work to the open air. It is strictly forbidden to cut PVC with thermal tools - the fumes emitted by it are extremely toxic.

The comment was sent successfully.