All About Shinogibs

When carrying out electrical work, specialists often have to use various professional equipment. One of them is the shinogib. This device allows you to bend various thin tires. Today we will talk about what these devices are and what types they can be.

What it is?

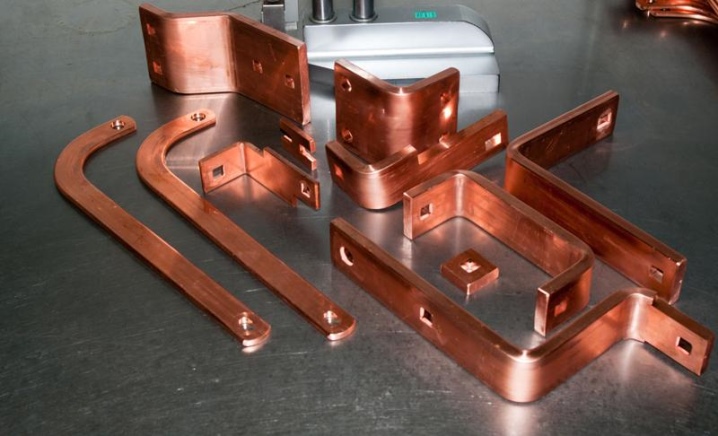

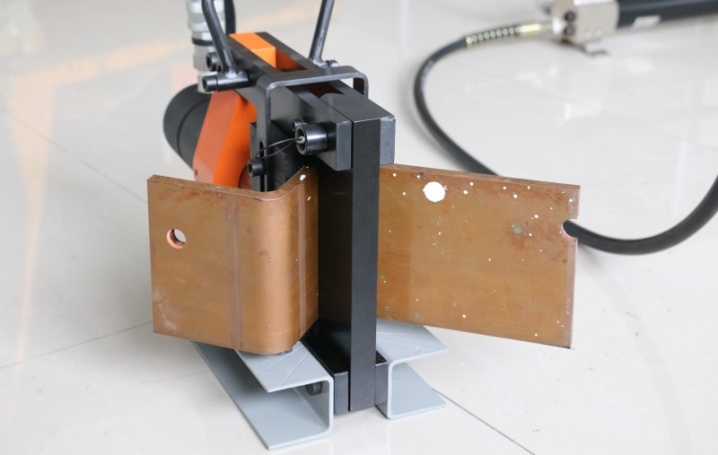

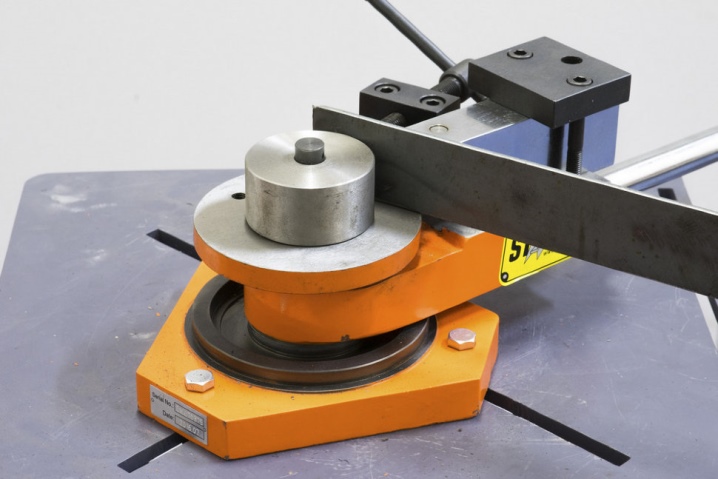

A tire bender is a professional tool that is usually hydraulically powered, but there are also manual-type models. They make it easy to bend aluminum and copper mounting rails.

Shinogibers make it possible to make bends as high-quality and accurate as possible, and at the same time the processed material will not become thinner.

In terms of its functionality, this unit almost completely corresponds to sheet bending equipment. At the same time, such devices are much more compact, therefore, unlike sheet bending machines, they can be easily taken with you to any object where electrical work is carried out.

Overview of views and models

Today, manufacturers produce various types of shinogibs. But at the same time, all of them can be divided into two large groups, depending on the principle of work:

- hydraulic type;

- manual type.

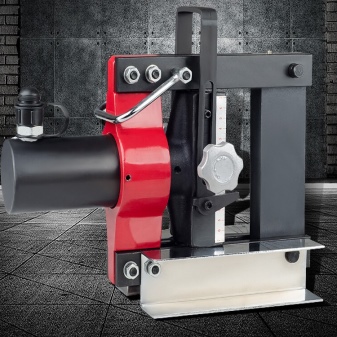

Hydraulic

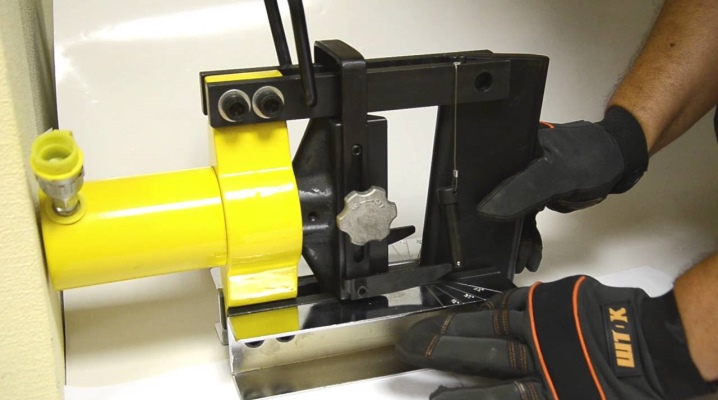

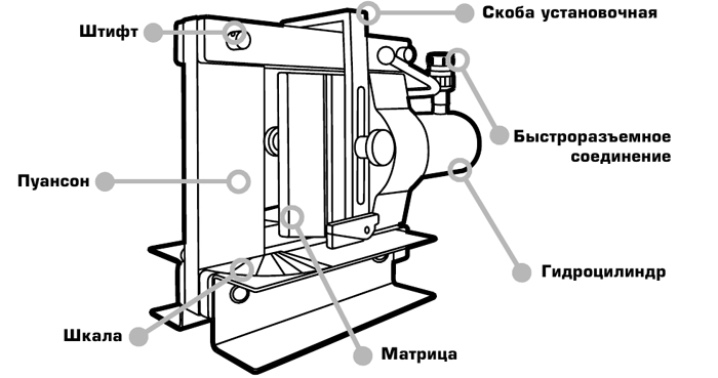

These models are the most productive and easy to use. They are equipped with a special hydraulic mechanism, which is able to create the required tire displacement using its stamp, which allows you to give the product the desired shape. Such devices are necessarily produced with a handle that drives a pump that distills a special oil.

Immediately after the pump is activated by the handle, the entire mechanism will create the necessary pressure in order to squeeze out the cylinder rod and deform the tire product. After that, it will be necessary to drain the hydraulic fluid, do this using the crane switch. At the end, the rod will switch to its original position, and the strip will be removed, all this will take only a few seconds.

The hydraulic equipment can boast of a high working speed, significant deformation effect. It can be used for the thickest and widest busbar structures. But it should be noted that it will require quite expensive maintenance, and the hydraulic fluid will have to be changed periodically.

Besides, these devices are often prone to breakdowns due to the complicated mechanism of operation. The working parts of hydraulic machines are punch and die. It is due to them that the tire can be given the desired shape. These parts are removable. The power in kW of such squeezing devices can be different.

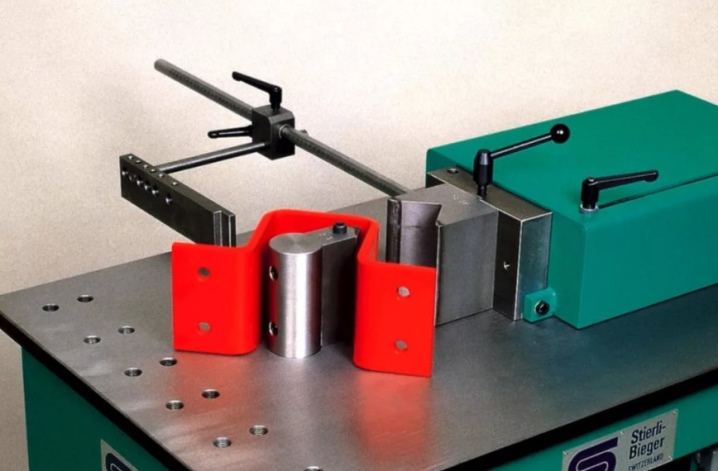

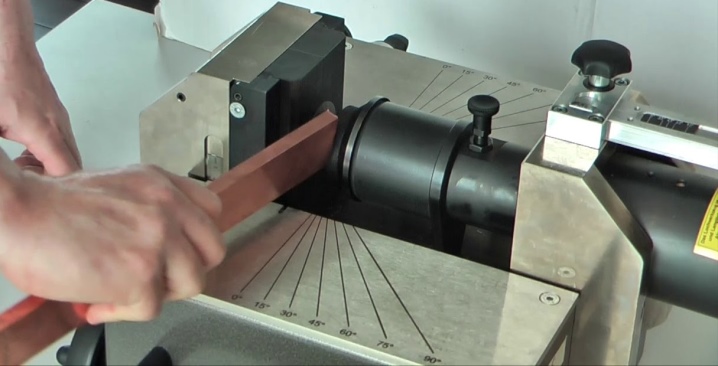

Manual

These units work according to the vise principle. They allow bending of aluminum and copper busbars. But they should be used for processing products with a small width (up to 120 millimeters).

Hand-held devices make bends at an angle of 90 degrees. They are very heavy, so you can't always take them with you. In addition, for the required compression, a person will have to apply great effort.

These types of shinogibs have a design in which a screw-type mechanism is provided. In the process of tightening it, the gap on the working section of the tool will gradually decrease, which leads to a mechanical effect on the material being processed, and it begins to twist and acquire the desired shape.Manual models allow you to control the degree of tire bending only visually. If you screw the mechanism to the end, then the product will be bent at a right angle.

These samples are relatively inexpensive. Moreover, they do not require expensive and complicated maintenance. It will be quite enough to lubricate it with special oil from time to time. It is also necessary to highlight the most popular models of this electrical installation equipment among consumers.

- KBT SHG-150 NEO. This unit has a hydraulic type, it is used for processing conductive busbar products. The model is equipped with a coordinate scale that allows you to precisely control the bending angle. The total weight of the device reaches 17 kilograms.

- SHG-200. This machine is also of the hydraulic type. It works in conjunction with an external hydraulic pump. The sample is also intended for bending current-carrying metal products. It provides even, high-quality right-angle folds. This model has a fairly compact size and relatively low weight, so it can be easily transported if necessary.

- SHGG-125N-R. This press is perfect for bending copper and aluminum busbars up to 125 millimeters wide. The total weight of the product reaches 93 kilograms. This shinogib is equipped with an external pump. Its fold-down top frame has handy markings that allow you to control the angle when bending.

- SHG-150A. This type of self-contained shinogib is designed to bend tires up to 10 millimeters thick and 150 mm wide. It can work with both a built-in pump and an external auxiliary pump. The model has a convenient marking with the values of the main angles. The working part of the sample has a vertical position, which provides maximum convenience when bending long products. This unit is considered to be as reliable as possible due to the absence of such quickly breaking elements as hoses, quick-release couplings.

- SHTOK PGSh-125R + 02016. This model will allow you to make the highest quality and even bend of the tires. It can be used for products with a thickness of up to 12 millimeters. In this case, the device immediately works in two planes: in the vertical and in the horizontal. This device can be driven by a special pump, which is usually purchased separately. SHTOK PGSh-125R + 02016 has a total weight of 85 kilograms. The maximum bend angle produced by the machine is 90 degrees. The power reaches 0.75 kW. It is distinguished by a special indicator of strength and durability.

- SHTOK SHG-150 + 02008. This tire unit is most often used in professional workshops. It has a vertical type construction. The model is equipped with a special corner profile, which makes it possible to bend even the longest products at right angles. The tool is created exclusively from the most durable materials, which makes its operational life as long as possible. But for the operation of the equipment, the connection of a special pump is required. The total weight of the structure is 18 kilograms.

- SHTOK SHG-150A + 02204. Such a tool will be the best option for small private workshops, sometimes they are installed in large production. This sample does not require the connection of special pumps to operate. It is completely autonomous. The variety has a small size and weight, so you can take it with you if necessary. The working part of the structure is of a vertical type, which is convenient when bending elongated tires.

Applications

As mentioned earlier, this equipment is used to shape various types of tires. It will allow you to bend the product at a certain angle without much effort. This tool will eliminate the need for a hammer.In addition, it produces a much higher quality work compared to the rest of the tools.

The mobility and compactness of such devices makes it possible to work with them directly at the tire installation site.

The comment was sent successfully.