Pneumatic nailer: features and tips for choosing

Nail guns, also called naylers, are used in a variety of applications, from construction to carpentry and furniture workshops. Despite the relatively low driving force, pneumatic nailers are at the top of the ratings.

Further, their features, models and characteristics are discussed in detail.

Peculiarities

A nailer is a device that is used to drive fasteners without using physical force. They are divided according to the source of energy into gas, electric and pneumatic (we will talk about pneumatic further) and by the type of consumables into staple, hairpin and nail.

The pneumatic hammer works in the same way as the nailer. Despite the fact that pneumatic nailer is related to hammering tools, there are opinions that pneumatic nailer is loaded with staples and not nails.

With the help of such a device, you can significantly speed up the process of construction or work with wood, clapboard or other materials.

Pneumatic nailers have several advantages.

- Good peak work rate. In general, it is 3 to 5 beats per second.

- Low cost. Since the operation of the device is based on the use of compressed air, this makes the total cost of a pneumatic tool less than that of devices with a different type of power supply.

- Impact power. The pneumatic hammer can drive nails all the way in with just one blow.

- Ease of use. For the operation of the pneumatic tool, it is not necessary to obtain permits.

- Low weight of the product. During work, due to its low weight, the hand does not experience discomfort.

- Working conditions. The principle of operation and design nuances of pneumatics allow work in conditions with high humidity or poor ventilation.

Apart from the main advantages, pneumatic nailers have some weaknesses:

- for the operation of the compressor, it is necessary to have high-voltage uninterruptible power supplies;

- to connect the pneumatic tool and the compressor, it is necessary to connect the air hose, which can create inconvenience, despite the fact that it may have a minimum length and weight (to avoid this, it is necessary to properly organize the workspace).

Models and their characteristics

Construction pneumatic nailers are divided into several groups.

- Devices that are used to work with floor coverings. The device drives special fasteners at an angle.

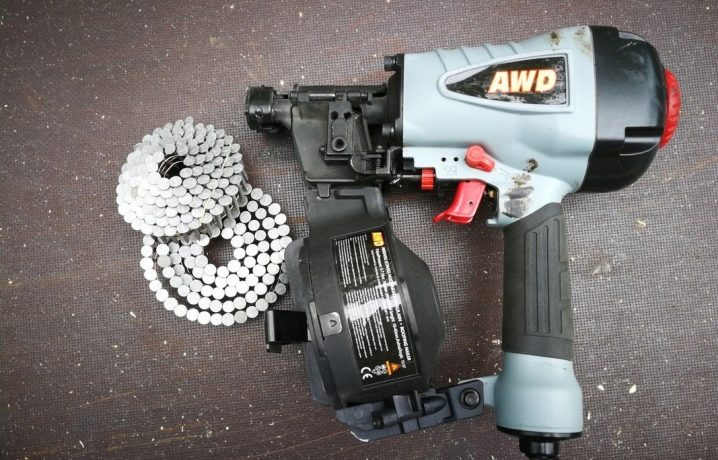

- Roofing equipment. Use up to 14 gauge fasteners with a length of 19 to 45 mm.

- Sheathing nailers. They are used for fastening plywood and various sheet materials, using 15 or 14 gauge fasteners with a length of up to 70 mm.

- Frame nailers. They are used for work with large fasteners with dimensions of 150-200 mm and are intended mainly for assembling frames and preliminary structures, in casings - inclined, straight and drum with an inclination of 21 and 34, caliber up to 11, length 130 mm.

- Naylers for finishing works. They are used when insulating facades, for installing skirting boards or platbands due to the use of short nails without hats, hairpins or pins, calibers up to 9 with a length of up to 130 mm are used.

- Direct mount devices. They are used when working with concrete, steel and bricks, or when fastening sheet plasterboard, fasteners with a length of 90 mm, 100 mm, or 130 mm are used.

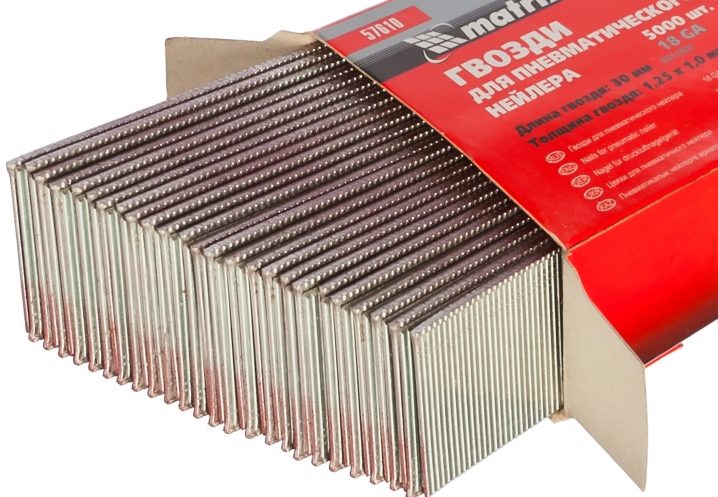

It should also be noted that within a certain caliber and length, various types of nails and studs can be used: smooth, brushed, screw, and so on.

Pneumatic hammering tools differ in some basic technical characteristics, which you should pay attention to when buying.

- Drum (device for placing fasteners). The weight of the tool depends on the number of accommodated nails.

- Depth adjustment, onto which the fasteners are hammered (in cases where the nails do not need to be driven in to the limit).

- Operating pressure. In the absence of compressed air, the nailer will not work.

- Safety device against repeated (accidental) clogging. Provides the ability to work safely and can minimize injury.

- Compressed air consumption per shot - a characteristic that affects the performance of the tool.

- The amount of air used during operation (for example, no electric motor). The pneumatic nailer is lightweight (the lightest type of hammering tools), which leads to maximum ease of use, as it can be useful in works where you need to keep your hand in the air for a long time.

Three companies are included in the rating of the best manufacturers of pneumatic hammers.

- The company's products are highly popular Bosch... Based on the reviews of the owners, it can be noted that the important advantages of these devices are the rubber handle and the electronic impact power regulator.

- Also, the models of the company are no less popular. Makita... While they do not have surprising performance data, these tools are robust and can provide reliable fastening of long nails in any solid material.

- Devices from the company are very high quality "Zubr", which has in the assortment all variations of nail hammers, as well as models for dismantling staples and nails.

Optional equipment

A feature of pneumatic nailing guns is that they need a compressor unit to work. For a successful compressor selection, it is necessary to build on the characteristics of the operating pressure and air consumption per shot.

For the operation of the nailer, a completely ordinary device with a pressure of 8 bar is suitable. The manufacturer specifies the specific compressor data for each nailer in the instructions.

Selection Tips

When choosing such a device, do not forget that they all have differences in purpose. In this regard, in order not to make a mistake in choosing the necessary model, it is worthwhile to look at a number of important points when comparing various options.

If you need devices for mounting plywood, lining or other upholstery materials to the crate, you should choose those that are equipped with a drum with the maximum possible capacity, since a significant amount of fasteners will be needed to complete the work. For fastening drywall sheets, it is recommended to purchase zinc-coated nails up to 5 cm long and a head with a large diameter. Any general purpose (or 2-in-1) air gun can handle this type of fastener, and there will be no need to consider impact power and performance. To more efficiently mount materials to hard surfaces, it is best to use a gas or powder nailer.

Due to the fact that during the operation of this type of tool, high temperatures are created, which arise due to friction during the entry of the fastener into the surface, they will ensure a strong fastening of the nails and minimize the risk of their falling out after a certain amount of time.

It is also worth considering, with the exception of the basic parameters, that the design of the nail gun has a large number of differences depending on the model. Therefore, in the case of various installation work, devices should be used whose design provides for the possibility of adjusting the driving depth. In some situations, the design of the escapement is important. Standard attachments use a trigger-shaped switch, but pneumatic nailers are recommended for rapid hammering, which fires shots by applying pressure to the tip. Also, nailers differ in the method of delivery of fasteners. For example, for large volumes of work, it is recommended to use devices that work in queues. High-precision driving can be organized only by devices with a single shot.

You should also be aware that a pneumatic device for driving nails is a very complex type of tool for construction., you should not purchase such a device for one-time use or a small amount of work. Therefore, when choosing a pneumatic hammering gun, you should pay attention to those products that have good recommendations, positive feedback on use and which relate to manufacturers of similar devices of popular brands.

How to use?

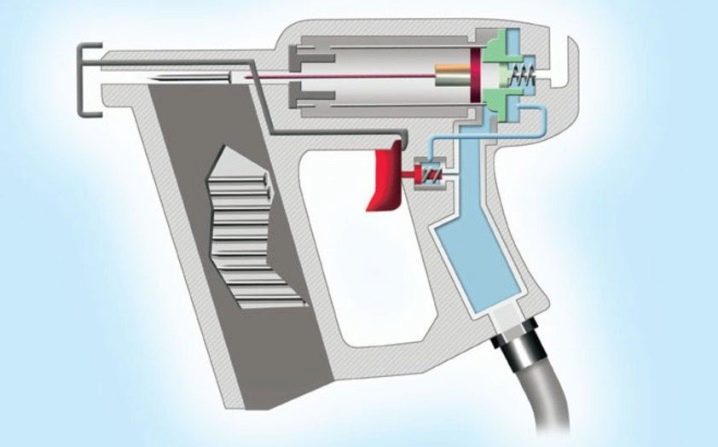

The main structural sections of a nailer are the tool sheath and the plunger, which is driven by a jet of compressed air. The whole principle of operation of this device is carried out in a two-stage cycle.

At the initial stage, the compressed air in the handle does not enter the main chamber of the nailer, due to which it affects the valve, which is located in the lid. Due to the compressor, the engine pumps the required amount of gas into the receiver before firing. After that, the gas under high pressure passes through the existing hose into the neiler. Pressing the trigger stops the supply of compressed gas to the cover. Due to the valve, the pressure of the gas jet pushes the plunger - the nailer begins to drive in the nails. After the trigger is released, the valve closes when exposed to gas, and the plunger returns to its original position.

Driving speed depends mainly on the skill of the worker.

Almost all pistols are equipped with a special-purpose mechanism that protects the device from unwanted shots. (it is referred to as the "clamp"). For these reasons, shots are fired only at the moment the device contacts the working surface. Also, during the operation of such devices, it is worth paying attention to safety precautions: to leave the tool during the working pause, set the device to the fuse.

For more information on pneumatic nailer guns, see the video below.

The comment was sent successfully.