Screwdriver: features, types and tips for use

A screwdriver is the tool “everyone knows everything about”. But in reality, this adaptation is much more complicated than it seems. Dealing with these features is important in order not to accidentally make a mistake when buying the right tool.

Specifications

The exact time of the invention of the screwdriver is unknown. But it is clear that its appearance is associated with the proliferation of firearms. Flat screwdrivers, invented in the 16th century, have not undergone almost any changes so far. But many other species have appeared, each of which deserves attention.

Any screwdriver, regardless of its size, has a handle into which a thin steel rod is inserted.

Modern manufacturers have long abandoned the production of screwdrivers with wooden handles. Plastic turned out to be much safer and more convenient. Either powder or injection molded plastic is used. The first option allows you to achieve greater hardness, but the product turns out to be fragile, its reliability decreases. The second version of the handle is more flexible. Many firms prefer non-slip rubberized grips.

To better understand what a normal screwdriver should be, it is useful to refer to the instructions of GOST. It should be borne in mind that tools for fitting and electrical work must comply with different standards. The regulatory documents prescribe clear standards of hardness, which determine the list of acceptable steel grades. The material of the handle is selected depending on whether the product is intended for contact with petroleum products in a liquid and gaseous state or not.

The standards normalize:

- torque;

- tip hardness;

- tolerances for the perpendicularity of the end and the symmetry of the groove;

- roughness of individual surfaces;

- type of protective and decorative coating and its thickness.

Where are they used?

As stated, screwdrivers were originally used in the manufacture and maintenance of firearms. Then they began to be used in mechanical engineering and maintenance of various mechanisms. Even later, this tool found application in the construction and renovation of houses. All of these areas of use persist to this day. But screwdrivers can be used much more widely.

There are special screwdrivers designed for hard-to-reach places. With their help, you can carry out repair and installation work even in the most confined conditions. To repair a smartphone, you need a different kind of specialized screwdrivers, which allows you to perform the most "delicate" work. The same tool is used when working with other electronics, with watches. Such a device is equipped with a special, thinner than usual, sting. For the nipple, use special screwdrivers (extractors). They help to insert or remove spools. Such a device is used in tire fitting. It is desirable to have it for all car owners.

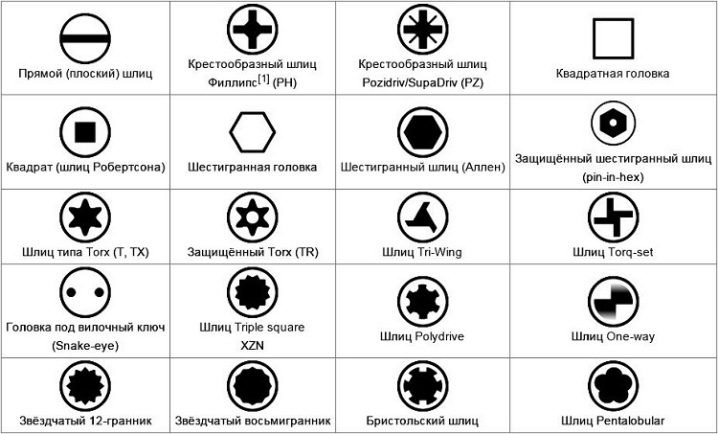

Views

Flat

This type of screwdriver is marked with the letters SL. They are also called straight-groove, straight-groove and simply straight - in them the working tip is made in the form of a flat blade. Such a tool can be successfully applied when working with screw connections. But the end portion cannot be centered. As a result, it will often slip out.

Cross

Such a screwdriver is also called a Phillips screwdriver and is marked with the abbreviation PH. A cross-like sting is able to fit into the splines of similarly shaped fasteners. As a result, you can connect and disassemble technical equipment, car parts. The cross connection is considered to be quite reliable, since the specific shape helps to increase the contact area of the tool and the head.

However, there is a high risk of deforming the helical splines. In addition, there is also a Phillips screwdriver with guide elements.

Hexagonal

This tool is marked with Hex symbols. By using it, you can significantly increase the rotational force (compared to using Phillips screwdrivers). In most cases, devices with six edges are used by electricians. If the protrusion is on the inside, the screw heads will break quickly. With the external location of the protrusion, you can work with screws, the heads of which are not recessed. Also worth mentioning are the vibration-resistant screwdrivers, the tip of which has a hole.

Star-shaped

These screwdrivers are identified with the Torx symbols. A similar tool allows you to repair many technical systems. Its peculiarity is a very powerful torque. The probability of the tips slipping off the screw heads is close to zero. The destruction of the splines is also excluded.

The range of screwdrivers that can be used by installers is not limited to the four listed types. Square jigs (with a matching slot shape) are not capable of generating intense rotation. These screwdrivers are mainly used in the USA. In the post-Soviet space, they are needed mainly by those who work with vintage cars. Flexible Shaft Screwdrivers are recommended for furniture assembly and other work in hard-to-reach areas.

The universal tool can be equipped with various types of handpieces. They are placed both inside the handles and in separate cases. This decision is made solely by the manufacturer. When you plan to work with energized structures, you will need dielectric insulated screwdrivers. A special feature of such a tool is a special coating of the rod part and the handle.

Important: the handle and accompanying documents must contain information about the maximum permissible voltage. Some screwdrivers come with a ratchet mechanism, which allows the working shaft to turn strictly to one side. Which one - determines the position of the special lever. As a result, it is possible to tighten or unscrew the screw without removing the tool from its head.

Rechargeable devices deserve special attention. They are close in organization to screwdrivers. The device differs from them in total mass and power. The reduction in power compared to screwdrivers is justified by the fact that no hole routing is required. But you can reduce the size of the tool.

Small screwdrivers, as already mentioned, are needed for working with watch movements and fine electronics. Attachments with angle bits allow you to work better where access is limited. Products with eccentric attachments can mount fasteners on edge lines, which is not possible with other tools. The universal double-ended screwdriver is most often equipped with a round handle. It is used when it is necessary to screw or unscrew various types of threaded connections.

Most often, they put a straight and cruciform sting. In some cases, it is advisable to use professional T-shaped tools. They are sometimes made with holders that allow you to install standard 6 mm bits with hex shanks.

More often, however, Torx bits are included.Compared to a typical T-handle, the handle is slightly larger, but the loss of compactness is offset by a noticeable increase in torque.

Therefore, it becomes possible to screw in screws and screws 100% with minimal effort. It also makes it easier to remove rusted fasteners. Another advantage of the T-shaped configuration is the minimal risk of shearing the spline. The short rods and handles of some of these screwdrivers significantly expand their area of application. Eliminates such an unpleasant situation as the need to spin the tool with your fingertips.

During operation, the T-shaped screwdriver is supported with one hand and the handle is struck with the other. This technique allows you to significantly increase the speed of work. Some companies even provide special plastic rings for this purpose. But it is worth remembering that screws wrapped in wood, as well as self-tapping screws, do not tolerate such handling. If you have to work only with bolts, then this drawback does not really matter.

T-shaped screwdrivers are also worth using in everyday life because of their low cost. Products of Asian "shed" workshops, together with a set of bits, are sold for about 200 rubles. Important: the shape of the letter "T" reduces comfort while working. Such a tool is not suitable if a strictly limited torque is required. And in other cases, you need to work with it more carefully so as not to damage the fasteners and material.

At home, ready-made screwdriver sets with nozzles are often used. Several working heads of various shapes and sizes are supplied for one handle. Even the increased cost of this option is fully justified.

With the right choice and skillful use, these devices can replace the full volumetric toolboxes. In addition to bits, some type-setting screwdrivers are equipped with socket heads that allow you to work with nuts.

Depending on the design, the working element changes in three ways:

- in conjunction with the rod;

- by swapping bits;

- by replacing the head.

The curved screwdriver is used for particularly sophisticated work, such as manipulating the scale screws on certain types of guitars. A feature of this tool is the mini-slot. Some craftsmen make it with their own hands. Sometimes the tip is brought to a grinding device. This allows it to be precisely matched to the screw slot.

It is customary to call combined screwdrivers with two-component or three-component handles. Some of them are distinguished by an increased level of ergonomics. And also some manufacturers provide protection against slipping of the hand. The delivery set includes sets of bits or stings. Depending on the needs of the customers, all this splendor is put into cases or placed inside the body of the pen.

The two-pin screwdriver deserves special words. Some types of these screwdrivers are manufactured with high precision. The best designs are equipped with non-slip handles, well-rotating heads. The Y-shaped device is used only in rare cases, it is only needed by professionals.

Products in the form of a revolver only look unusual, but at the same time they effectively fulfill all the tasks assigned to them. Such a tool allows you to show your originality. The weapon-shaped screwdriver can be supplied with cases that look like a revolving holster. To enhance the effect, a special drum is set aside for storing drills. If you need a more practical tool, you can opt for a power screwdriver.

The shock-rotary device allows you to fully convert the impact energy into rotational energy. “Fully” means not completely (this would contradict the laws of nature), but thus transform energy so that negative effects and accelerated wear can be eliminated.An impact screwdriver works in much the same way as a bolt. The sting in such a tool runs along the entire length from the slot to the end of the handle. The blade blade is a monolith, while the use of welding or other methods of joining is categorically unacceptable.

Important: the working part is made strictly from first-class alloy steel.

You can maximize the potential of the device by giving the tip a hexagonal shape. Experts recommend working together. The spline parts are placed on the screw to be machined, then the hexagon is covered with a key, after which they begin to inflict fractional blows on the back side. Simultaneously with these blows, they try to twist the instrument.

Attention: for technical reasons, it is unacceptable to use impact screwdrivers as a bolt. They are not strong and massive enough for this. In addition, such a technique threatens to get injured.

At home, magnetic screwdrivers are widely used. This tool helps to drive screws even where it is inconvenient to place and support them with your fingers. The end part can be magnetized even in artisanal conditions. It is only required to pass 2 or 3 times the pole of the permanent magnet in one direction. If the need for magnetic properties disappears, you can get rid of them by swiping the same pole several times in the opposite direction. The so-called minus screwdriver is simpler than most of the options already mentioned. This flat mechanism is used less and less now.

Compared to those designs that were invented about 400 years ago, modern minus screwdrivers are more complicated. For the manufacture of the slot, hardened and sometimes hardened metal using a special technology is used. It is covered with notches to reduce the likelihood of the working part slipping out of the channel. Additionally, a magnetic material is deposited. The slots in screwdrivers must not be sharpened to a high sharpness - only a blunt end will allow you to keep the screw heads intact.

It is appropriate to complete the review on screwdrivers used in electrical engineering. The terminal type is used if you need to remove or reinstall the terminals of various devices. Using such a tool, it is possible to install conductors in connectors and terminals. A regular insulated screwdriver helps:

- screw and remove the wires;

- install and remove electrical outlets;

- install switches and other rigidly fixed devices.

Important: the highest level of protection is limited to 1,000 volts. If it is necessary to work with installations under a higher voltage, it is strongly recommended to use a highly specialized tool.

It is not permissible to replace an insulated screwdriver with a conventional screwdriver, even if it has a rubber-coated handle of an impeccable quality. Normally, the handle is made of polyethylene or polycarbonate, and in both cases a layer of formaldehyde is applied. Devices that are impermeable to current are almost always equipped with a flat or cruciform sting; other forms of tips are extremely rare.

Rating of the best models

In order to choose the right screwdriver, it is important not only to determine the appropriate type, but also to take into account the features of a particular brand, model. Among the instruments made in Germany, noteworthy Bosch Ixo 5 set... This product has been designed with a number of innovations. The cordless screwdriver is equipped with a lithium-ion battery. The developers paid attention to the constant illumination of the working area with LED lamps.

Other advantages are:

- automated spindle lock;

- high quality corner bit;

- handle of increased ergonomics.

Another high-end German-made battery device is Hammer ACD3.6LE... Consumers note that it is possible to screw and unscrew the screws with this screwdriver in the shortest possible time.Even heavy contamination or a significant amount of rust will not hurt. The designers took care of transferring the handle to the position that is most convenient for confined spaces. The nickel-cadmium battery is frost-resistant.

Among the Japanese screwdrivers, it stands out Vessel megadora... The 900 series is considered standard, while the 910 has a relatively thin tip. The Model 930 Power Tool may have a shorter shank than usual. The 970 product is a hybrid of a simple screwdriver and a chisel. It is worth considering that the Japanese approach implies a preference for outdated splines over modern options.

Accessories

In practice, special accessories are of great importance. Changeable bits allow you to flexibly tune the tool to certain operating parameters. So, with the help of bits made of chrome vanadium steel, you can cope with even the tightest fasteners. Holders help to securely fix and work even where you cannot hold a screwdriver with your hands. Covers and organizers greatly simplify storage and movement of the device in any conditions.

How to choose?

Having become familiar with the instrument, it is not difficult to understand that its choice must be very careful. A set, which includes a rod, an end part and a handle, is much more practical and convenient than a monolithic product. The ability to change bits allows you to flexibly adjust to certain manipulations. It is recommended to pay attention to the material from which the handle is made. Rubber inserts will help prevent calluses.

The optimum tool shank is made from tough steel grades that contain a lot of alloying additives. This part is the most resistant to corrosion processes. Even contact with technical oils and exposure to high humidity do not affect its condition in any way.

When making up a set of screwdrivers, one must also take into account the mechanical strength of the tips, their geometry, length and external section. An overly weak or too hard blade is very easily damaged.

When you plan to work constantly, you should give preference to cordless screwdrivers. Basically, these models are needed for car services and furniture workshops. Assembly operations are best performed with dynamometric devices. This screwdriver helps to achieve the highest precision. Versions with flexible shafts are recommended for tightening self-tapping screws in hard-to-reach areas.

Subtleties of operation

A screwdriver for any job must have a profile that matches the profile of the fastener. Even if they are outwardly similar, but not interchangeable, this circumstance must be strictly taken into account. Attention should also be paid to the consistency in size. It is often helpful to magnetize the tip of a screwdriver. It is categorically unacceptable to use it as other tools.

A chisel, a lever, a wedge, a knife, and so on - all these functions require specialized tools. The shank of the screwdriver must not be tilted in relation to the axis of the screw. Do not use the tool if the tip is worn out, the handle is deformed. And also the use of electrical screwdrivers with broken insulation falls under the ban. It is forbidden to heat the rod and handle to more than 70 degrees.

Operation of the tool at negative temperatures above 40 degrees is undesirable. Store it only in dry places. After finishing work, be sure to remove all the dirt and shavings. To unscrew a screw with torn off edges, you must use not an ordinary, but an electric screwdriver. Attempts to simply push harder on the hand tool can destroy the structure.

For information on how to choose the right screwdriver, see the next video.

The comment was sent successfully.