Choosing and caring for paint brushes

To carry out work using paintwork materials, paint brushes are required. These are cheap and easy to use tools, but they have poor performance, the paint layer is not evenly applied. To achieve a high-quality finish, you need a set of several brushes designed for different types of paint work, types of surfaces and paint composition.

Peculiarities

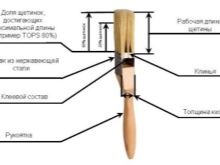

The making of paint brushes is subject to GOST 10597-87, according to KOSGU, these products are tangible assets. According to these technical standards, the paintbrush contains several elements.

The main functional component is the bristle. It is fixed in the clip by means of an adhesive, and the clip, together with the pile, is attached to the handle. The bristles of the brush in the holder are divided by several inserts, they form the working chamber space for varnishes and paints.

The number of inserts and their size directly depend on the dimensions of the tool and have a significant impact on the overall quality of painting. For example, if the number of liners is disproportionate to the size of the brush itself, then the density of the pile packing will be low. Accordingly, the applied coating will not adhere well to the substrate, and the paint exchange parameters of the tool will be significantly underestimated. The inserts are made of plastic or wood. Paints often come into contact with water, wood deforms under such conditions, so professional workers choose the first type of tools.

The bristles, inserts and the clip are planted in an adhesive solution. The pile is attached to the entire height of the liner. The period of operation of the painting tool directly depends on the characteristics of the glue used: in budget models, cheap adhesive solutions are used, in expensive ones - epoxy glue.

If the adhesive characteristics of the composition are not enough for a firm hold in the holder, the pile will begin to fall out, and this will significantly reduce the quality of processing.

Views

There are many varieties of paint brushes. They differ in pile length, base size and design. All these differences are of key importance when choosing a working tool for a particular type of repair and finishing work. That's why it is very important to be able to understand the features of brushes and their functional purpose... This will allow you to choose the right toolkit in accordance with the upcoming work.

Handbrake

This is a large brush, the length of the working part is 20-30 cm. The pile is held on to the shortened handle with a thick metal rim. A similar tool is in demand when tinting small surfaces or when priming.

Handbrake brushes are used when working with slowly drying paintwork materials, which do not contain a caustic solvent. The main advantage of such models is their high resistance to aggressive solutions.

Facing brushes

Such brushes are used when decorating a surface treated with enamel with a slight roughness effect. For this, the coating is applied to the prepared surface with sweeping strokes.

To achieve the desired texture, such a brush requires high-quality care - it should be kept perfectly clean.

Maklovitsa

The tool is rounded, the diameter of the working part is up to 17 cm. Some models can have a rectangular or square shape with a block width of up to 20 cm. The products are distinguished by exceptional performance and do not need additional leveling of the tinted surface after applying the enamel.

This instrument is indispensable for water-based LCI.

Flight feathers

Brushes of this type are suitable for tinting, but they were most widespread when performing whitewashing... The tool is in demand for working on large areas. Brushes are made from natural bristles with the addition of 20-30% synthetics.

The main advantage of such a tool is its resistance to water and the preservation of its functional characteristics when working with solvents and other aggressive components of paintwork materials.

Flutter

These brushes have found their way when leveling the applied paint. With the help of such products, gross defects are smoothed out.

They are usually used as an independent tool in a situation where there is a need for a finishing glossy layer.

Paneled

Relatively compact brushes, the diameter of the functional part is no more than 2 cm. Used when you need to draw a straight, thin line.

Fillet models are most widespread when decorating surfaces using the ombre technique to design a gradient transition.

Flat

Flat brushes are used for priming and wall painting. The tool is produced in a wide range of sizes, the width varies from 30 to 100 cm. The bristles of these products are tapered.

Varieties of bristles

Modern paintbrush manufacturers use a wide variety of materials to create bristles.

- Natural bristles... It quickly absorbs and gives off well all types of coloring compounds, with the exception of water-based paints and varnishes. In most cases, pork backbone bristles up to 7-9 cm long are used for manufacturing. To assess the quality of such a pile, the parameters of elasticity and strength are used. They can be black, white, yellowish and light gray in color. White is considered the highest quality and strongest; it is obtained by bleaching.

- Natural hair. This bristle is characterized by low elasticity, therefore it is rarely used in its pure form for painting work. It has a scaly layer, due to which it perfectly absorbs and gives off the coloring composition. It can be tough and thin. Coarse hair is made of hard horse hair, soft hair is made from hairs of fur-bearing animals. In the painting industry, only the first option is used.

- Synthetic bristles. It is made from fine nylon fibers, slightly less often from polyester and polyester. It is characterized by increased resistance to abrasion, elasticity and softness, but demonstrates a weak LCI fence. This problem is eliminated by artificially splitting the tips of the bristles and forming additional channels in the cavity. It can be used for all types of paints and varnishes, including water-based formulations. Thanks to the development of technology, the quality of synthetic threads is growing every year, so brushes with synthetic bristles are becoming more widespread.

- Mixed... Two-component pile includes both natural and polymer fibers. Thanks to this composition, a combination of the best operational types of pile is achieved: resistance to wear and retention.

With the help of various types of synthetic fibers, you can adjust the parameters of softness, elasticity and other characteristics of the dyeing.

Dimensions (edit)

Separately, you should dwell on the size of the paint brushes. The tool should be chosen not only by the external characteristics and the type of bristles, but also by the dimensions of the functional part. The overall quality of finishing works directly depends on the correctness of the selection according to this criterion.

- Tool diameter up to 25 mm it is used when applying LCI to narrow surfaces (rods, glazing beads, small-sized elements).

- 38 mm - suitable for painting round surfaces, narrow skirting boards, window frame edges and ceiling cornices.

- 50 mm - found their application in the tinting of stair railings, window frames and baseboards of standard sizes.

- 63-75 mm - universal models, in demand when painting wall surfaces and wide structural blocks.

How to choose?

For painting work, several types of products are usually required. For example, a flange model is needed for a finishing coating, a manual model is suitable for preliminary calibration, and a panel tool is used for processing corners.

In addition to the quality and bristles, the material of the handle should be assessed. The most budgetary option is a wooden handle. But it is better to refuse products coated with varnish - they will not give a strong grip. Such instruments in the course of work will constantly express from the palms of your hands. The most expensive option is plastic, brushes with such handles are expensive, but the plastic does not get wet, does not dry out, it is quickly cleaned of dirt and paints and varnishes, and lasts more than one year. Depending on the height of the surface to be painted, the handle is short, long or has a special extension.

Other factors are also considered quality parameters.

- Frame... The most widespread is a steel bandage - it is durable and resistant to any organic solvents. However, brass belts are more reliable, they are less susceptible to corrosion and deformation. The plastic clip does not rust, although it loses its shape upon contact with some solvents.

- Beam density, the so-called "tops" number. This indicator should be high - such brushes are not cheap, but at the same time they hold varnishes and paints with high quality. The paint exchange characteristics of the tool are at a high level.

- Adhesive composition. Reliable, practical and durable brushes, the bristles are attached with epoxy glue. It holds all the lint in place, thus ensuring a high quality surface finish.

Do a little test in the store - tug at the nap. If the bristles fall out, then such a purchase should be discarded immediately.

Manufacturers

Most often in stores sellingBrushes from several manufacturers are available.

- "AKOR" - the largest manufacturer of finishing tools in Russia, the assortment list includes paint brushes of all types.

- "Master" - the enterprise specializes in the manufacture of hand-held painting tools (brushes and rollers of a wide range, intended for both single use and professional use).

- "BrashTech" - produces paint brushes for all types of painting works.

- "Cote d'Azur" - is engaged in the production of paint brushes, technical brushes and spatulas. All products are manufactured on the most modern equipment using advanced technologies.

The list of domestic companies engaged in the production of paint brushes also includes:

- "Comfort";

- Inmaxo-Lacra;

- "RaDeliv";

- Brush-brush factory;

- Vema;

- "Yarvil";

- "Zubr OVK" and others.

Care rules

In order to extend the life of the brush, you should adhere to several rules for caring for it.

For a new instrument

A new or unused instrument must be washed with soapy water before use. This will remove all dust and broken bristles. After cleaning, the product must be wrung out and dried.

Before painting

- Soak the tool... The fiber should absorb moisture and increase in volume - only in this case the brush will apply paintwork smoothly and evenly.

- Develop... The functional part must take a precise conical shape. To do this, paint is covered with a small area of concrete or brick.

After painting

- Clear... The painting tool is cleaned with kerosene and then with soapy water.Alternate these treatments until the water is clear and clear. Soda helps to remove paint residues - for this, a soiled brush is immersed in soda gruel for 2-3 hours, then washed in cool water.

Important: after any wash, hang up and dry the instrument thoroughly. It is advisable to store the brush in a special container.

The comment was sent successfully.