Nippers: what is it, types and application

In the huge variety of construction tools used in the household field, special attention should be paid to wire cutters. Thanks to this common tool, everyone will be able to cut through many types of materials without disturbing the structure. In addition to maintaining structural integrity, high-quality and fairly neat cuts are obtained.

In any market for construction tools, consumers are offered a variety of cutting pliers., each of which differs in its properties. For a more detailed understanding of the importance of this tool, you should familiarize yourself with its characteristics and features.

What it is?

Nippers are a unique tool. Possessing an uncomplicated system, it easily cuts not only plastic, but also metal materials. The principle of operation operates on the basis of a lever system. Despite the simplicity of appearance and the usual way of operation, the wire cutters have unique abilities. They can cut the wire, easily cut through electrical wires, effortlessly divide the power cable into several parts with a maximum thickness of 7 mm. Any dismantling work, installation of other equipment is carried out using nippers. Even the smallest electrical tasks cannot be accomplished without the use of this tool.

The main thing is to remember that each separate type of work requires the use of a certain type of wire cutter.

Types and characteristics

Nippers are designed for separating many types of materials. Accordingly, the tool should be chosen for the forthcoming work based on the basic requirements. Despite the peculiarities of each individual model, all nippers are made according to the same design principle. They have a comfortable grip, thanks to which they are comfortable to hold in the hand, and cutting edges, which have the second name - sponges. Each individual variety can be determined by design parameters, more precisely, by the shape of the edges, their location and dimensions.

- End cutters. In this design, the jaws are folded perpendicular to the handle.

- Side cutters. A simpler name is side cutters. The jaws of this variety are located at the smallest angle relative to the handle. In some cases, on the same line. Due to its enhanced function, the tool is mainly used in the construction industry.

- Power cutters. Another name is bolt cutters. They are used in work with metal rods.

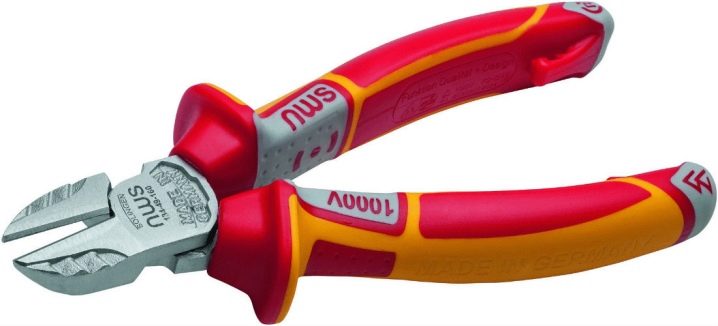

Quite often, wire cutters are used in work with electrical networks. To ensure the safety of the master, the tool handle is made with the addition of special insulating materials. In simple terms, electrical cutting pliers are equipped with an increased level of insulation and are able to protect hands from a strong electric shock.

In this case, the handle design is divided into two types - insulating and insulated tools. The difference lies in the coverage. Insulated models are made of dielectric filling, but tools with insulating materials are equipped with cutting inserts. The handles themselves are presented in the form of lever guides.Their surface does not wrinkle and, which is very important, does not slip out of your hands. Easily tolerates wet environments, grease and chemicals.

Among other things, wire cutters are divided according to the area of use.

- Screw cutters and reinforcing cutters. Designed for work with metal.

- Electrical. Manufactured to separate thick cables into several parts.

- Professional. Used for cosmetic procedures.

Rebar nippers are used for working with hot wires. Strong steel is used in their production. The comfortable handle is standard 21 cm in length. It is made of PVC material and has overlays on which powder paint is applied.

Electrical cutters are designed for separating insulated cables. The maximum permissible thickness for a male dog for separation is 35 mm. Knives made of alloy steel that have undergone preliminary heat treatment are used as a cutting edge.

Professional hand cutting pliers are used in many beauty salons, as well as at home. With their help, both manicure and pedicure are done. The only difference is in the connection design. It can be soldering, crossing each other, or a spring. The dimensions of the instrument are small and fit comfortably in the hand. It is mainly used to remove cuticles. Stainless steel is used as the material for creating the tool.

Hydraulic

In appearance, hydraulic cutters resemble ordinary shears, only of a large size. This tool has an increased spectrum of action. It can be used to divide strong joints of various types of metal into several parts. The maximum pressure force of the hydraulic cutter is 250 tons. Basically, this tool is used by rescuers to evacuate people from crumpled cars.

Diagonal

Made to separate wires of different thicknesses, made of aluminum and steel materials. The design of the diagonal side cutters is equipped with tilted heads relative to the lever and a hinge with an axis that can withstand constant monophonic loads.

Dielectric

This type of cutter is made for carrying out repair work with live wires and wires. The handle of the dielectric model is made of a special material that does not conduct electricity and can protect the master from electric shock. It should be understood that the use of electric cutters is possible with a maximum electrical voltage of 1000 V.

Pneumatic

This type of wire cutter is distinguished by an increased level of reliability. It is the most necessary tool for working with metal products, surfaces made of plastic, steel structures. Pneumatic cutting pliers are mainly used in workshops and garages. The main function of this tool is the ability to cut through strong material in a curved line.

Precision

This type of wire cutter is designed for the most delicate and jewelry work, for example, for separating the finest wires of electronic equipment. During the manufacture of the cutting edge, the metal used was additionally quenched with a high frequency current. In weight ratio, the tool is 20% lighter than its counterparts. The design of the precision cutters is equipped with a double spring, which is responsible for an easy stroke and smooth, uniform opening.

Roller

Nippers of this type are designed for cutting materials such as tiles and glass. With their help, the basis of the decorative mosaic is prepared. Despite their small size, they can separate large sheets of ceramic tiles into small particles.The design of the tool is quite simple: a durable and comfortable handle, the surface of which does not slip in the hand, a connecting spring that allows you to make a smooth pressure. The main structural element is the rollers themselves, they are made of durable steel, very sharp. The main purpose of the roller cutters is to cut the base material for finishing work.

Victory

Victory-tipped pliers are mainly used in the construction industry. They enable the master to carry out work with more powerful wires and cables, while not putting in huge efforts. It should be noted that victorious nippers have a higher working life than conventional models. And all thanks to durable victorious pads located on the surface of the biting edges.

How to choose?

To purchase high-quality nippers for repair work, you should pay special attention to the tightness of the edge contact. When compressed, there should be no irregularities, notches or cracks. It is very important that the edges are on the same level, do not overlap each other when they touch.

To find the most suitable model, you should experiment with the tool handle itself. It should fit comfortably in the palm of your hand when you pinch your fingers, which creates a comfortable working environment.

It is important to make sure that the material from which the nippers are made has moisture-resistant properties, does not come into contact with various lubricants, does not slip in the hand and has a rather massive body.

Application

After reviewing the information presented above, it becomes clear that each separate type of wire cutter plays an important role in different areas of activity. Painters and decorators of massive structures use roller side cutters to create mosaic patterns. The same tool helps tiles when cutting non-standard sizes of ceramic tiles and tiles. That is why the device has a second common name - tile cutter.

Hydraulic models in various modifications are used in metal work. This particular tool is used in many rescue operations. They can cut through steel cables and chains of various thicknesses.

Pneumatic cutters are generally used in the manufacture of plastic structures. They cut material easily and simply, leaving a neat cut. Due to the evenness of the cut, the maximum compaction of the individual elements is created.

Diagonal cutters will help cut the wire into multiple pieces. And the victorious ones will allow you to remove the caps from the nails with a single press. In addition, victorious pads have a beneficial effect on the process of biting knitting needles and screws, while leaving an even cut.

Operating rules

There is an opinion among the people that any nippers are the simplest tool in the construction business, they assure that there are no difficulties in its operation, and any person can use them. In fact, each separate type of wire cutter requires compliance with certain rules proposed by the manufacturer.

- The nippers should be positioned directly at right angles to the item being cut.

- Do not press the handle very hard. Powerful impact may break the tool.

- It is important to closely monitor the process of the tool. Quite often, the surface to be treated begins to crumble, and small fragments fly off in different directions. Therefore, the presence of strangers during cutting is undesirable.

- In order to bite off a piece of wire, it is necessary to use the special indentations of the nippers, and not their tip.

- When separating the material, pay attention to the edges. They must completely close together. If the sponge begins to diverge, the work will have to be stopped, otherwise the cutting elements of the tool will break.

- Using a heavy-duty wire cutter involves a double workforce, where one person has to hold the piece to be cut and the other to cut accordingly.

- Despite the scope of activity, each master must have certain ammunition in order to protect himself in the process of work.

Quite often, with prolonged use, the edges of the device begin to dull. Accordingly, they need to be sharpened. If you have the required equipment, you can carry out this procedure at home, but it is best to give it to a workshop.

An overview of the side cutters can be seen in the video below.

The comment was sent successfully.