What is the difference between a chisel and a chisel?

Many people mistakenly think that a chisel and a chisel are one and the same tool. Both tools are used to treat a variety of wood surfaces. Popularly, both names usually mean the same thing. Yes, outwardly they are similar, but their application is different.

What are the differences?

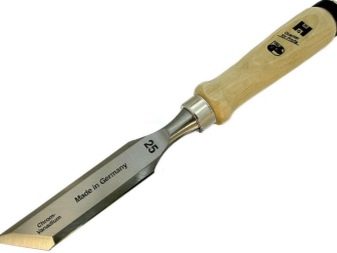

The main differences between the tools are in the use of different kinds of steel in their manufacture. Also, chisels and chisels have different purposes. For chisels, thinner metals are used, so this tool is used for delicate and delicate work. Nevertheless, the steel in the mixtures is extremely strong and well sharpened. A dull chisel blade will leave ragged edges when cutting wood.

The chisel, on the other hand, is a rougher tool and is used to apply strong blows with a mallet to it. There is also a metal ring on the wooden handle of the chisel, which enhances the reliability of the wooden handle. Many chisels have plastic handles, because they do not have such a heavy load.

What is a chisel?

The chisel is one of the most popular tools for manual woodworking. The tool has a wooden (less often plastic) handle and a metal cutter. The chisel has several varieties, each of which is designed for a specific type of work. The varieties are as follows:

- Flat view. This is a standard tool model that is very common among professional carpenters and in the household. The flat chisel has high strength, as it is used in work where it is necessary to apply large forces. The cutting blade is rectangular or square.

- Oblique view. From the name it follows that the blades of such a model of the joinery are beveled and have a trapezoidal shape. It is convenient to use this tool to make grooves with straight edges or to process material corners. The sharpening angle of the fixture can be from 25 to 30 degrees.

- Mini chisel. Such a tool is often used by professional carpenters. It is convenient for them to perform delicate work that requires a lot of painstaking work.

- L-shaped. With this type of joinery it is convenient to form a right angle on the material, as well as choose rectangular and square grooves.

- Big type. Such a device is unlikely to come in handy in a household. It is usually used for surface treatment of large workpieces. The large chisel has a long and wide blade and a thick and long handle. It is convenient to use this tool to remove bark from large workpieces. This chisel is used by professional carpenters.

What is a chisel?

A chisel is a carpentry tool with which workpieces of small thickness are processed. When working with a chisel, no other tools are used, while when working with a chisel, a percussion tool is used - a mallet. The chisel can cut small grooves, grooves, chamfers, etc. Also, many chisels have a slight thinning on the blade closer to the handle. The chisel usually does not have such thinning. The width of the chisel blade is also different from the chisel. At the chisel, the blade is wider, and at the chisel it is narrow and can start from 6 mm.

GOST

For the production of joinery tools, there is a special GOST, which indicates the main standards and characteristics that the manufacturer must adhere to.According to GOST, chisels are divided into flat and semicircular. Specified types of steel from which the blades should be made - 9ХФ, 9ХС, ХВГ. Tool handles should be made of oak, beech, hornbeam, maple, acacia, ash or birch.

Manufacturers

When choosing a carpentry tool, it is important to pay attention to the manufacturer's brand. There are several brands that have proven themselves from the best sides. Among them are the following.

- "Anchor". This manufacturer produces chisel sets that are perfect for beginners. The handle of the tool is wooden, the blade is made of durable alloy steel, which increases the service life of the chisel. The sets have tools of different sizes, among which you can choose a chisel for any type of work. Also, this manufacturer has a very attractive price for its product.

- Stanley. Chisels of this manufacturer are designed for delicate woodwork. This tool has a two-piece handle and the blade is made of durable high carbon steel. Therefore, such a tool can be used to process even the most durable types of wood.

- Matrix. This manufacturer produces chisels and chisels for deep processing of wood, thanks to the long blades. The handle of these tools is usually rubber, but extremely durable, which allows you to hit the chisel with a mallet without fear of damaging it.

- Narex. The tools of this manufacturer are used by experienced carpenters. The cost of such chisels is higher than that of other brands, but these tools are highly reliable. The chisel blade does not dull even with daily use.

Work rules

Working with any carpentry tools is a rather delicate and demanding business. Both the chisel and the chisel must be well sharpened so that the edges of the grooves are even. The shape of the future grooves should be marked on the workpiece. To work with a chisel, use the effort of the hands, carefully cutting out grooves and other grooves. But if the material is quite strong and does not lend itself to pressure, then a chisel and mallet are used. It is a wooden hammer that hits the handle of the chisel.

In such work, it is extremely important to calculate the impact force so as not to damage the workpiece. And you should not forget about personal safety - negligence can damage not only the material, but also the hands. The blows should be short and light so that the mallet does not jump off or knock out the tool. So, although the chisel and chisel are similar, the main difference lies in their purpose and the use of different materials in the manufacture.

For more on how a chisel differs from a chisel, see the video below.

The comment was sent successfully.