Chisel: what is it, types and characteristics

Chisel is a term that combines a slotting tool widely used in joinery and carpentry practice, as well as in drilling wells for the production of gas, oil and artesian water.

What it is?

During the excavation of ancient burial mounds and cities, archaeologists quite often find the remains of ancient wooden dishes, which directly indicates that our ancient ancestors were fluent in the art of woodworking. In Russia, all buildings and the entire arsenal of household utensils, from the simplest furniture to tools, were originally made of wood. With the development of technology, the manufactured objects of labor and everyday life were updated more and more elegantly, and all because the craftsmen were able to create various effective tools, among which the chisel played the most important role. This tool is relevant in our time, including the one that has practically remained in its original form.

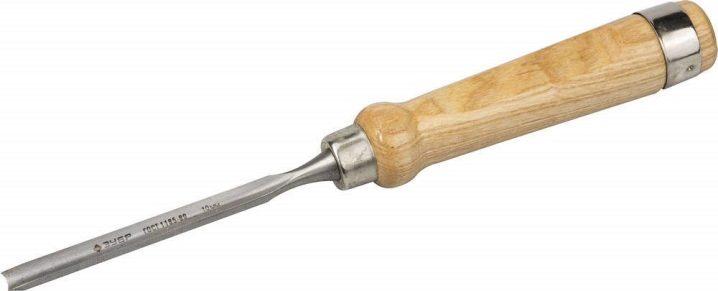

The chisel is a simple device that is indispensable for gouging small holes, spikes and sockets during rough wood processing, as well as for cutting wooden blanks to the desired shape. This is a steel bar of square or rectangular shape, tapering slightly towards the sharpened end. Tool sharpening is usually one-sided.

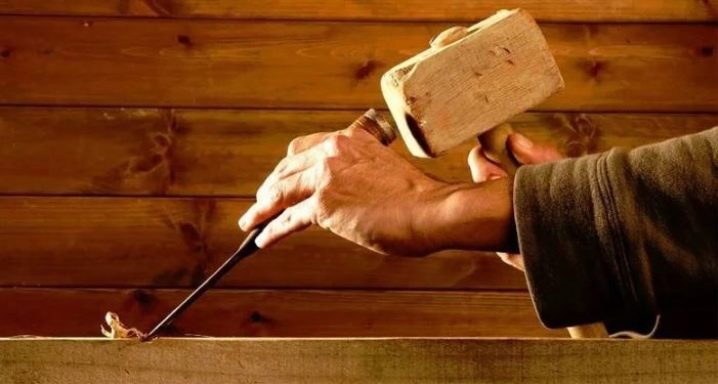

The bit is distinguished by a fairly tight fixation of the shank of the cutting part in the handle. The strength of such an attachment is due to the cap with a sealed neck, which allows a rather large force to be transmitted. When processing wood, the chisel is exposed to high loads, since the gouging of grooves in hard bases is accompanied by sharp blows from the mallet on the handle, which is why the handle is made either from hard wood or from polymers with high hardness. If the handle is made of wood, it is additionally reinforced with a metal ring, which increases the strength of the part and prevents the material from cracking.

Less common is a chisel with a semicircular base - such a tool is indispensable for cutting grooves, as well as cleaning the corners of the workpiece. And also on sale you can find U-shaped canvases, which are optimal for the formation of recesses for door hinges.

Types and characteristics

Depending on the size of the tool and the shape of the cutting blade, the chisel can be used for a wide variety of woodworking tasks. The chisel blade can be square, semicircular with different diameters, pointed, sharp and even similar to a drill. According to the features of operation, the classification includes milling, electrical, pneumatic and manual models used in construction and carpentry.

Thus, a beveled chisel has a trapezoidal blade, an elongated blade, and a beveled edge. Such a tool is indispensable for knocking out grooves with right angles and smooth edges, it is used for processing corner parts. The blade has a long bevel, so that the tool can penetrate the most difficult to reach places where any other type of tool cannot get through. With the help of a semicircular chisel, fibers are sampled from the inside of the log; such tools in appearance and functionality are very similar to a chisel.

A tapered chisel is unlike any other - its blade is longer and thinner, and the cutting edge is much more beveled. The shape is generally rectangular and is ideal for deburring after chiseling. The mini chisel, as the name suggests, is the smallest model that is suitable for delicate and delicate work. The L-shaped chisel is widespread - it is used to knock out grooves, as well as square holes for mounting fittings and forming straight edges in wooden blanks.

The long chisel has found application when carrying out work related to the need to penetrate into the material., its distinctive feature is its flexible and long blade. The slick belongs to the hand-type tools - this is a rather large chisel, the blade of which reaches 60 cm in length, and the width approaches 10 cm. Such models are rather heavy, therefore physical efforts are required to work with it. Slik is used in rough carpentry and shipbuilding.

The wide blade tool is good for general construction and renovation work, it is used for removing parquet boards, dismantling screeds and paint coatings. Varieties of beveled bits have a sharpened oblique edge, usually sharpened at an angle of 45-60 degrees, while the blade can be sharpened in any direction. The most popular types of chisels are considered carpentry and joinery.

Plotnitskoe

Carpentry is also called flat and thick, it has become widespread among craftsmen whose activities are related to wood processing. Such a tool has a fairly dense working blade, and the blade has a rectangular or square profile. The blade is characterized by increased strength, therefore, they are popular when carrying out work that requires the application of significant physical effort.

Joiner

A carpenter's chisel is a hand-held tool. It is performed with plastic or wooden handles, while the holders can be both removable and non-removable - the change is usually made in order to change the nature of the blow - with a mallet, hammer, hand. The cutter in most models is rectangular - it is quite convenient for them to carry out the most simple manipulations to create grooves and small nests in a tree. Slightly less common are models with a semicircle cloth - they are suitable for grooving small grooves and cleaning corners.

The working edge has a special sharpening, due to which the degree of mechanical stress is determined. The blade is made of tool steel, the most expensive models are additionally hardened and anti-corrosive.

The drill bit deserves special attention, which differs significantly from the joinery. To begin with, the borehole lance is a rather complicated packing, which is completed with a set of spherical and cylindrical segments made of high strength alloys. The most technologically advanced models include bearing mechanisms, due to which, when colliding with rocks, the segments continue to move. Such a device is compatible with drilling rigs, rotary percussion machines and units for vertical soil development. The drilling tool has a rather complex device and large dimensions than the carpentry tool - it is used to break hard and soft rocks, as well as dense soil.

Comparison with other tools

Many novice craftsmen confuse a chisel with some other tools - most often a chisel. The product is a hand-held device with a grooved or flat cutting blade. The length of the blade varies from 4 to 40 mm, most often in their work joiners and carpenters use several chisels in turn.

The chisel and chisel are similar, but the main difference here is the steel used - a thinner one is chosen for the chisel, since this tool is designed to perform delicate operations. While the chisel is used for slotting operations. The steel in the chisels is denser - this is the only way to ensure accurate cutting of the material. If the tool turns out to be blunt, then it will break the wood fibers and the surface of the workpiece will turn out to be rough and uneven, requiring improvement.

The chisel handle features an easy-to-press dome shape. It cannot be used to strike - otherwise the handle will simply fly into small pieces.

The bit works as a result of the application of a mechanical force of the percussion type - in other words, they hit it with a hammer or a mallet, which is why the handle is equipped with a crimp ring. The chisel is used exclusively by hand. The chisel looks very similar to a chisel, the principle of operation is similar, but the chisel is used for woodworking, and with the help of a chisel they work with concrete, metal and stone - this causes some design differences between the tools.

Features of choice

The chisel is an indispensable tool for cutting corner cuts, as well as for creating a wide variety of grooves. And since physical efforts are applied to it, then the design of a quality tool must be appropriate - the width of the blade should not be less than 35–40 mm.

Keep in mind that the chisel is a tool with a wooden handle, a high impact force is applied to it, therefore, despite the presence of a ring, the handle often has a tendency to crack and as the material wears out, the risk of the handle splitting and injuring the worker increases. That is why it is better to give preference to those tools in which this part is made of the most durable types of wood - oak, hornbeam or maple.

Pay special attention to the metal from which the blade is made. The steel should be tool steel that has undergone additional hardening, as well as coated with anti-corrosion compounds. Otherwise, the tool quickly becomes dull and breaks. If possible, try the instrument at the time of purchase. For example, choose the one that is "on the hand" - remember that you will have to hold it under a hail of blows, so it must be securely fixed in your hand.

Be sure to find out how the blade is attached to the handle. The cheapest models are shank-based - they are comfortable to grip, but the shank of the handle acts like a wedge, which loosens the fasteners. Over time, the handle may split or fly off the shank during work. In addition, purchase the tool from a reputable retail outlet and ensure that the chisel meets all GOST requirements.

For information on how the chisel differs from the chisel, see the next video.

The comment was sent successfully.