What is a shrinkage compensator and why is it needed?

Shrinkage compensators - devices used in wooden housing construction to prevent such a phenomenon as shrinkage of a bar or log... They are installed at the stage of erection of a building or structure, provide the necessary pressure on elements that change their geometric parameters as they dry out. Features of the use of an adjustable screw shrinkage jack for a bar, other types of compensators, the principles of their operation should be studied in more detail.

Operating principle

Wood is a material that undergoes certain deformations in the course of changes in the moisture content of its fibers. Under the influence of atmospheric moisture, wind, sun shrinkage occurs, changing volumes, affecting the tightness of the joints to each other. All these factors are especially important in housing construction. When using a log and a bar of natural moisture, the formation of inter-crown gaps is almost inevitable.... The shrinkage compensator helps to eliminate this unpleasant effect.

Depending on the type of materials, the annual shrinkage reaches 2-5%, and it takes up to 3 years to complete the process. This is a serious problem when arranging door and window openings, which can lose up to 6-10 cm. This leads to jamming of the shutters and other difficulties.

It is also not recommended to carry out interior decoration of the house before the shrinkage is completed. Materials can just rip.

Shrinkage compensators are introduced into the structure of a log house and allow in the future to successfully control the processes taking place in it. Depending on the presence of additional regulators, the pressure on the side of the strut remains constant or changes. For example, a jackscrew is evenly displaced monthly throughout the year, allowing shrinkage to pass without damaging the entire structure.

The basic principle of operation is as follows.

- The compensator is installed at the most vulnerable points of the structure.

- Keeps the crowns in a given position during deformation and shrinkage processes.

- Allows you to adjust the uniformity of shrinkage. When installed on vertical pillars and columns, the dimensions of the gaps are calculated in advance, and they are gradually reduced.

- Upon completion of shrinkage, removable elements are removed, non-removable ones are left in the structure of a building or structure.

The use of expansion joints helps to avoid many unpleasant consequences associated with drying out of wood, ensures the preservation of the correct geometry of all joints.

Varieties

All shrinkage expansion joints used in the construction industry are usually divided into 2 large categories: adjustable and unregulated. Depending on the choice and characteristics of the material, the observed deformation loads, the types of devices used may also vary.

Fixed spring

This type of shrinkage compensators is a metal product installed in the body of a bar or log at the stage of construction work. They are not removed from the structure after the completion of the construction process. The design itself is as simple as possible: between the steel bowls there is a spring that takes on deformation loads.

For installation non-removable expansion joints shrinkage, preliminary drilling of holes in the body of a bar or log is used. After installation, the role of such components in the structure is reduced to maintaining the downforce even when the geometry of the element itself changes. Spring expansion joints good in that they neutralize the effects of deformation resulting from temperature changes, and not only during natural shrinkage.

For their installation, a docking area is chosen, located between 2 or more walls. This is where this structural element is most useful and necessary.

Screw or jack

This type of removable shrinkage compensators consists of 2 parallel plates with a bearing pin and nuts for fixing the support. When the screw element is tightened, it is possible to regulate the pressure parameters on the part of the wooden structures. In this case, compensation for changes caused by natural shrinkage is monitored and made throughout this process. Screw or jack metal products are made of zinc-coated steel. They are characterized by the following indicators:

- 100-250 mm height adjustment of the stud;

- cross-section of the bearing element - from 15 to 30 mm;

- plate sizes from 100 × 100 mm to 250 × 250 mm.

The dimensional parameters of the screw expansion joints are determined by the dimensional grid of the load-bearing beams used in wooden housing construction. The plates are attached to the building structure elements with screws through special technological holes. Screw expansion joints they are most convenient when used with a timber, since they have high bearing capacity, provide a snug fit of the spacers to the wood surface. At the time of installation, the stud is given the maximum length, and then, using an adjusting screw, its dimensions are selected taking into account the required level of sagging of the beam.

Nageli

This type of shrinkage compensator has existed for many centuries and was one of the first to appear. Nog - a wooden element that connects the crowns. When the wood dries out, the wedge does not allow the originally set distance to change. But this method is only suitable for laminated veneer lumber or log cabins. Sawed and profiled material gives more intensive shrinkage, the force of the dowel will not be enough here.

The dowel looks like a regular, carefully turned cylindrical plank made of harder types of wood than the frame itself... This difference makes it possible to overcome deformation loads. For example, oak or birch pins are used for coniferous buildings. They replace nails when assembling the house, they are hammered into the middle part of the timber, making a step of 2000-2500 mm, the holes are pre-drilled in a checkerboard pattern. The standard diameter of the birch spacer is 18-25 mm, the length is 300-350 mm.

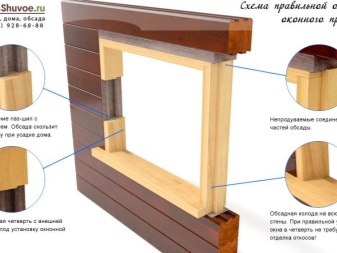

Casing

These expansion joints are designed for installation in door and window openings. A casing is assembled from dry lumber, which looks like the letter "T" laid on its side. The spacer is docked according to the thorn-groove system, a notch is cut at the ends of the opening, and a ridge is cut on the casing element. Casing structures are inserted on 2 sides, and the upper bar is already attached above them. This design prevents deformation and jamming of window and door frames in openings.

Where is it applied?

The main application of shrinkage compensators is associated with the construction of buildings and structures with a horizontal type of laying of a bar or log. In this case, when shrinking, they give the greatest deformation. The log jack is installed with an emphasis on the vertical elements, allowing you to further put it on the chosen base. This technology is fully justified in cases where designs are created for sale.

Screw compensation elements most often they are used in the presence of a vertical support connected to a horizontal base. Adjustable building shrinkage is the only real way to control changes in the moisture level of a bar or log. With help special expansion joints it is possible to avoid destruction, cracking of materials, to prevent the formation of cracks in the walls.

The types of shrinkage compensators of the timber are presented in the following video.

The comment was sent successfully.