Choosing a cyclone for a construction vacuum cleaner

Vacuum cleaners are indispensable devices for cleaning premises both in residential apartments and in offices and production workshops. Depending on the purpose, industrial and household electrical appliances are distinguished. This article will focus on construction vacuum cleaners and filters for them.

Purpose and varieties

Filters are installed in modern models of vacuum cleaners. Main varieties:

- cyclonic;

- aquafilters.

The principle of operation of the cyclone is known to everyone - the movement of the sucked-in polluted air occurs in a spiral, while litter and dirt under the influence of centrifugal forces remain on the walls of the flask.

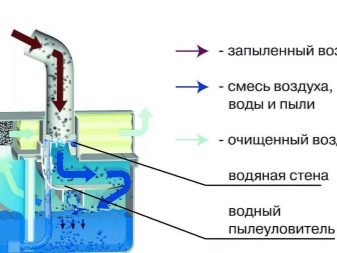

The action of aquafilters is also self-explanatory - dusty air and debris enter the aquatic environment and, when wet, remain in the lower part of the filtering device. The advantages of this type include highly efficient cleaning of the atmosphere - the cleanliness and moisture content of the air at the outlet is much higher than that of vacuum cleaners with other filters.

Due to this, vacuum cleaning devices with this type of filtration are in demand in families with small children or persons prone to allergic reactions. Among the disadvantages of such devices, one should note the high price and increased dimensions and weight. In industrial dust suction devices, a cyclonic filtration system is most often implemented. It should also be noted that these machines can be connected directly to those machines that generate a lot of litter and dust during operation.

How to choose?

When choosing a cyclone-type vacuum cleaner, you need to pay attention to the following indicators.

- The power of the device. The larger it is, the better the dust suction performance.

- The volume of the reservoir for dust and debris. Choose the best option for yourself, because with a large volume of the dust collector, the mass of the vacuum cleaner also increases significantly, as does its dimensions, and a small reservoir can overflow at the most inopportune moment.

- Suction power. These data are not always indicated in the technical characteristics of the goods, so you can focus on the total power of the electrical appliance or check with the seller.

- Additional filters. They increase the quality level of room cleaning. The best option is if the device includes HEPA carbon filter layers.

- Attachments and additional items included in the purchase kit. They increase the ease of use and the quality of cleaning various surfaces.

- Mass and method of movement of the device. Naturally, the higher the weight of the device, the more difficult it is to move it around the room. Pay attention also to the material of the wheels - it is best if they are rubber. Plastic materials can not withstand stress and break or damage an expensive coating.

Features of cyclone filters

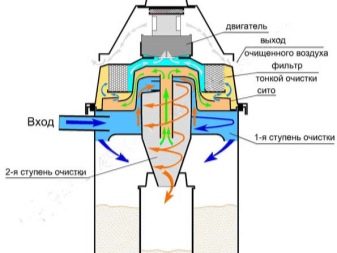

Among the advantages of using vacuum cleaning devices with cyclonic filters, it should be noted the versatility of use, durability, efficiency and reliability. In industrial vacuum cleaners, the principle of two-level filtration is implemented. When a clogged air stream is sucked in, it is separated by centrifugal forces. Most of the debris remains in the outer flask, the inner cyclone is busy filtering the smallest dust and performs the function of dust collection.

The cyclone filter does not require replacement and is not clogged with dust, which is another advantage of this design. Relevant for cleaning large areas.In industrial vacuum cleaners, tanks are provided for collecting litter and dirt.

And one more important clarification: litter particles, the diameter of which is less than 5 microns (plant pollen, bacteria, dust mites, etc.), do not stay in dust collectors of this type. To filter this type of debris, additional filter attachments (sponges) are provided.

How to do it yourself?

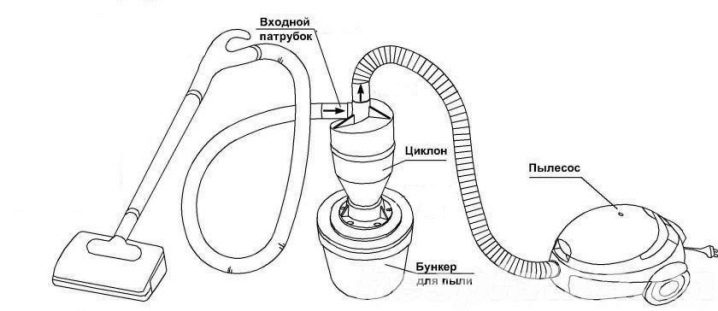

Industrial vacuum cleaners with cyclonic filtration are not available to everyone - they are profitable only for large areas with constantly accumulating volumes of debris. If you have your own small workshop, and during work, wood or metal debris is constantly formed, which you are already tired of removing by hand, assemble a homemade cyclone-dust collector, and you will greatly facilitate your work.

The first step is to decide if your cyclone is designed for wet or dry cleaning. In general, the assembly technology is the same, just for cleaning the moistened litter there are some small nuances. As a cyclone flask, you can take an ordinary bucket of oil paint or alabaster.

When choosing a capacity by volume, be guided by the power of the vacuum cleaner: 80-100 W should have 1 liter of volume, that is, if you have a 1000 W device, you will need 10-12 liter dishes.

There should be no chips or cracks on the lid of the container; it should ensure the tightness of the closed bucket. Of course, for a cyclone, it will be necessary to drill holes in it that are diametrically opposite in location. The diameter of the future channels is 54 mm, at least 4 cm should separate them from the edge of the cover. Next, you will need several sewer corners at 45 and 90 degrees. The position of the knees should follow the air flow vectors.

Insert the corner into the socket all the way. Before that, do not forget to grease the side with a hermetic silicone compound. On the other side, slide the rubber O-ring over the flare. The inlet channel must be placed with a narrow beveled part inside the container, its opening (bell) from the outside should hardly stand out at the level of the lid. Position the exhaust duct the other way around: its opening should point towards the inside of the bucket.

Insert one or two sewer elbows into this socket - for air outlet from the wall or from the center of the tank. Secure the joints with rubber rings or fix with tape (plumbing). A weighty plus of using sewer pipes when designing a cyclone is that their sizes are compatible with the diameter of most vacuum hoses.

If you plan to use the vacuum cleaner in parallel - both for cleaning living quarters and for the workshop, purchase an additional hose. Divide this corrugated pipe into sections of approximately 1/3 and 2/3 of the total length. Leave a short piece of hose attached to the vacuum cleaner. Insert the second piece into the opening of the cyclone inlet.

If you wish, you can strengthen the fixation of the joint with a hermetic compound or tape.

How to make a cyclone filter for a construction vacuum cleaner with your own hands, see the video below.

The comment was sent successfully.