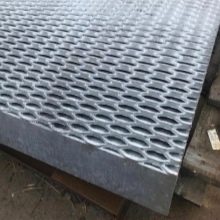

All about sheets of PVL 506

People interested in sheet steel want to know everything about sheets PVL 506. This is one of the types of rolled products - products manufactured on special equipment using variable methods. PVL 506 is used in various fields - household, construction, industrial, in the design of buildings and premises. This leads to a wide range of sizes and the use of different materials for manufacturing. Ease of use, relative ease of design, production on modern machine tools with computer programs, dimensional accuracy are the main reasons for the demand for this metal product.

Peculiarities

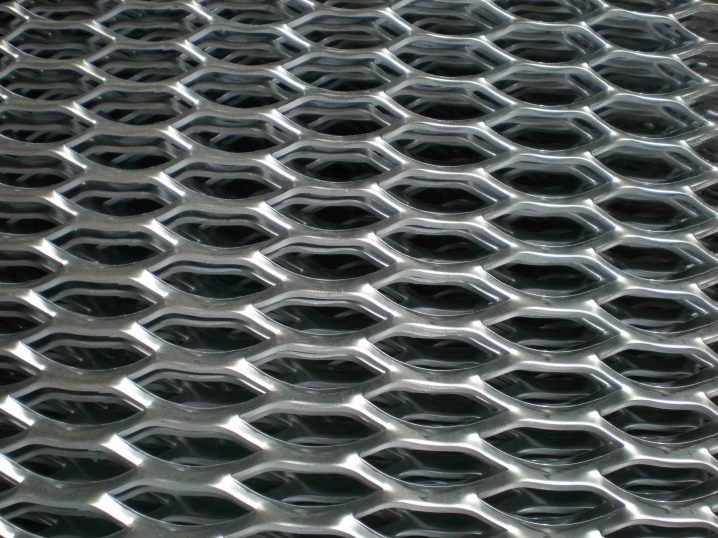

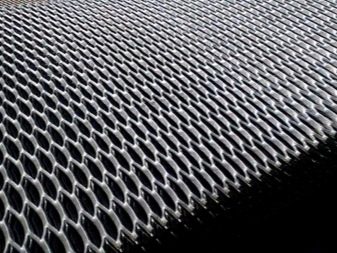

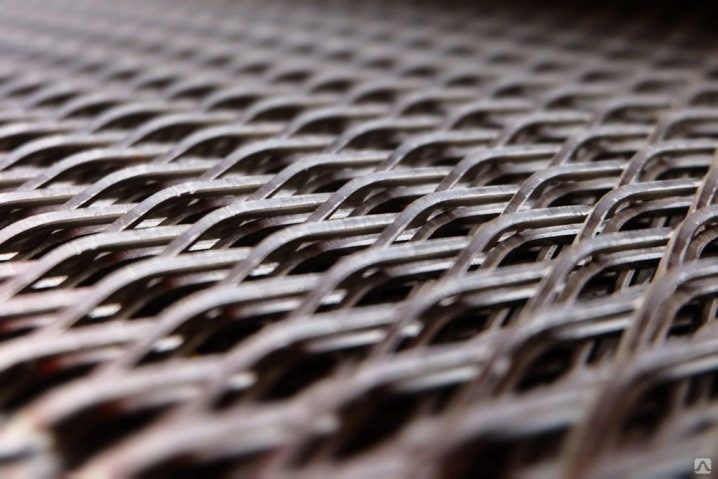

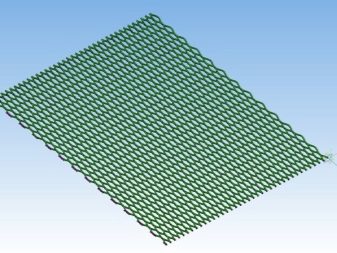

PVL sheet 506 - lightweight construction, manufactured on modern machine tools with computer programs. This is a representative of a wide range of rolled products of wide application - expanded metal sheets. They are distinguished by the presence of cross-sections on the surface, production from rolled sheets or rolls by synchronous pulling and passing through pressing rolls to fix the web, making it resistant to any deformations. Sheet steel processed in this way is distinguished by:

- high strength, but less weight (reduced weight makes installation and use easier, but does not mean that the product is less durable);

- guaranteed resistance to wear, provided by rolling along the long axis of the holes made, which makes the sheet flatter;

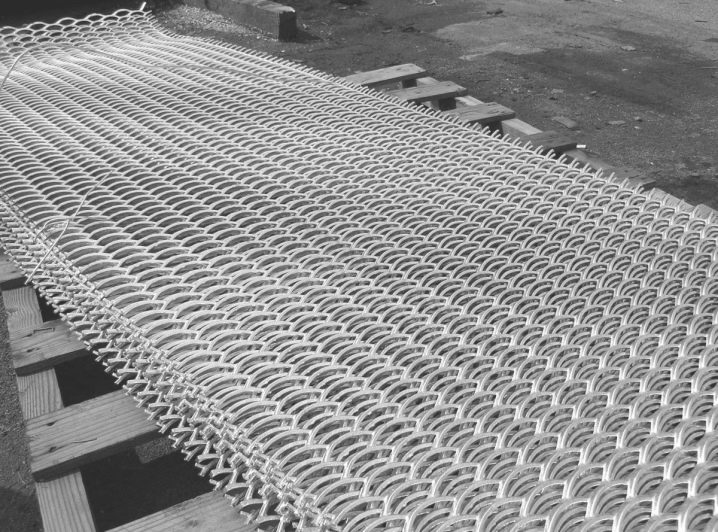

- notches made in a checkerboard pattern with a special knife, in two versions - rhombuses or scales;

- compliance with the dimensions specified in the regulatory documents.

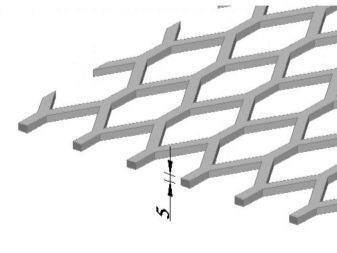

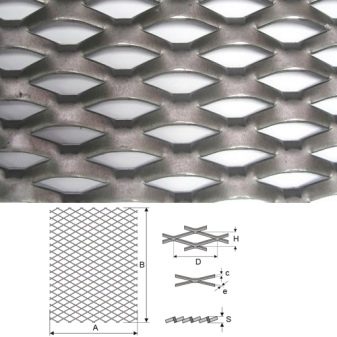

Expanded metal sheets made according to TU and GOST differ from each other by several parameters - the thickness and length of the sheet used to manufacture the product, as well as the width of the finished product. The brand of the sheet regulates its parameters in terms of feeding, the amount of extraction per 1 stroke and the mass of a square meter. The sheet of PVL 506 is made from rolled products with a thickness of 5 mm, feeding in 6 mm, with a cell pitch of 110 mm. The finished product weighs 16.4 kilograms per square meter. m.

Less material is consumed on such sheets, functionality is not inferior to perforated sheets, but the cost is lower and production takes place without toxic emissions. Their field of application is much wider, since PVL can easily withstand very low temperatures and unfavorable weather conditions (precipitation, frost, exposure to ultraviolet radiation).

Nuances of production

PVL sheet 506 Is a material with a wide range of applications, and its characteristics are determined by the consumer's intention to use it for certain purposes. The marking determines the dimensional characteristics specified in the TU and GOST, but it also indicates other parameters that must be taken into account:

- the type and number of the groove (scaly or diamond-shaped, which have slightly different purposes);

- dimensions of the material;

- steel or metal used in the manufacture.

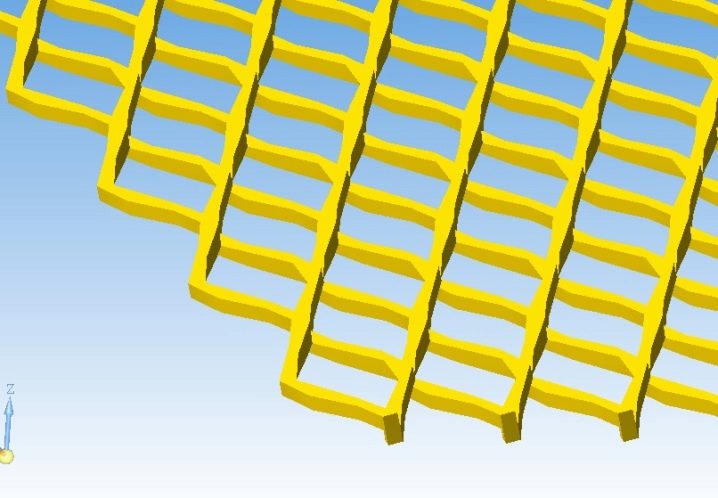

In production, professional CNC (programmed) machine tools are used, into which the terms of reference are entered. Modern equipment provides control over the application of the slots, drawing in the desired direction and degree sufficient for the cells to acquire the desired shape, passing through the rolls necessary for the final resistance to deformation.Rolling gives the finished product an aesthetic appearance and smoothness, the area of painting is calculated using a special formula or using a calculator available on construction sites.

Steel sheet PVL can be made of different materials, at the request of the client and according to technical requirements. For example, carbon or alloy steel with optimal parameters, which is recommended if welding is expected for a finished product. St3kp / Gsp - expanded steel (for steps and spans), stainless steel - for long-term operation and corrosion resistance.

Depending on the scope of application and the required decorative effect, it can be made of aluminum alloys, brass, bronze, or be galvanized.

The machines apply slots, pull the rolled stock until it acquires the desired shape, and at the final stage it is passed through the shafts. There are nuances in these processes - cold-rolled or hot-rolled, measured or off-gauge, with variable billet thickness, depending on the characteristics of the material and its use. PVL sheet weight 506 per sq. m can be within certain limits, and this is taken into account when the purpose of the purchase is already known.

Dimensions and weight

The technical characteristics of an expanded metal sheet of a certain brand differ in several parameters. Large manufacturers provide tables of expanded metal dimensions specified in GOST and TU (you can see TU36.26. 11-5-8). State standards are in GOST 8706-78.

- the mass of 1 square meter is 16.4 kg, but there are options when the product weighs up to 18 kg;

- the cell pitch is always 110 mm;

- dimension thickness - 13 mm;

- the price is considered - for 1 / m2, per ton and depending on the material of manufacture;

- length - no more than 3.5 m;

- the step of application is 1.25 cm.

In addition to the standard size of 1000x2000, expanded metal sheet made of structural carbon steel can be made in sizes 1000x3000, 1000x2400... The choice of material is made taking into account specific goals, in this regard, you can get advice from the sales managers that each modern manufacturer has.

Applications

Weight, excellent characteristics and the ability to cleanse have provided these products with widespread use, popularity among representatives of various fields of activity, industrial and individual developers. From such a sheet you can do:

- stairs, marching and street - they are perfectly cleaned of dirt;

- platforms for the convenience of servicing production lines, units and transmitting devices;

- fencing of factory territories, private estates, enclosures with animals (ventilation, illumination and lack of windage are provided to the owners);

- reflectors for variable devices - from protective grilles to viewing windows and transport barriers;

- lining in mines and reinforcement of concrete structures, a preliminary layer when applying plaster on external and internal walls;

- sieves in the processing and extractive industries;

- ramps, storm drains, gutters, decks and passages.

Recently, products made of brass, bronze, aluminum and even anti-corrosion steel are widely used in private construction for the safety and decorative component of balconies, verandas, terraces, gazebos.

Trellis for climbing plants and vegetables can be taken from a cheaper material, but for this purpose, such a sheet satisfies all the needs for which it is intended by the owner of a country or land plot.

Storage and transportation

Large consignments are transported by rail, smaller ones - in cargo vans or on-board vehicles. The open method is less beneficial, since in this case the pack has recommended weight restrictions. The advantage of using such a material is in a mass that is lower than in a solid or perforated product.

Rolling, which provides smoothness and decorativeness, contributes to additional operation and safety during storage in warehouses or even under a canopy, in the open air. However, you should not rely on general recommendations for storing a bulk batch.

It is imperative to take into account individual parameters - the steel grade, the type of alloy, its susceptibility to corrosion, the ability to deform under weight loads, the presence of a protective layer.

Each consumer, in addition to consulting with the manager about the plans for use and the choice of material of manufacture, can additionally secure their structure from the destructive effect of the atmosphere - for this, coloring compositions have been invented that give the metal additional stability.

The comment was sent successfully.