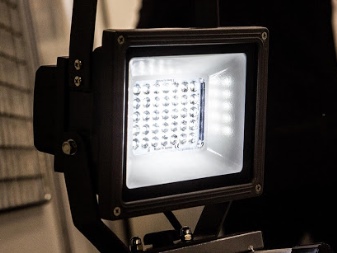

Repair of LED spotlights

A floodlight with LED components differs from other lighting devices in reliability. However, no one is immune from its failure. A timely repair can correct a large number of defects and achieve the main goal - to restore the device to work. It is worth carrying out repairs in cases where the spotlight does not have enough bright light, as well as when it completely refuses to work.

Breakage signs

Incorrect work of a searchlight, as a rule, will manifest itself with the following signs:

- when the power is activated, the led lamp is heated;

- the LED is flashing;

- the operation of the lamp manifests itself in a weak and dim glow;

- the luminous flux takes on an unnatural shade.

This list of features is basic. The following defects are also distinguished, which indicate the malfunctioning of the searchlight. This includes mechanical damage, deformation on the diode, overheating of the electrical wiring.

The reasons for their occurrence can be caused by the following factors:

- the unstable nature of the electrical network, namely the presence of voltage drops that go beyond the operating current value;

- incorrect connection of equipment;

- overvoltage in the network;

- application of overcurrents;

- short circuits on the device.

Such malfunctions in the operation of the floodlight occur when the elements on which the driver or converter components are installed, which provide power supply to the matrix, are lost. The conversion element may have damage to the internal crystals in the amount of 3-5 units. This will allow him to continue working in the same mode.

However, if the number of damaged crystals increases, then the equipment will lose its ability to function properly, which will lead to the need to replace the matrix part.

Diagnostics

Before starting the repair work, establish the reason that caused the malfunction of the searchlight. For this, it is worthwhile to carry out a number of diagnostic measures. For example, we can take a searchlight, whose matrix includes nine diodes, to test the operability of a rectangular shape. This equipment has a total luminaire power of 10W, and the luminous flux reaches 750 LM. In such cases, the diagnosis should be carried out in a specific order.

- Examine the integrity of the wiring by visual inspection. The presence of possible breaks or damaged insulation is checked. Also look at the cable for kinks. This helps to ensure the integrity of the conductive cable.

- Carefully examine the body of the searchlight device and examine the matrix where the LEDs are located for integrity, determine the presence of deformation, chips or cracks.

- The input voltage is checked. Be sure to open the rear panel of the case. The input indicator should be within 220 volts in alternating current. The absence of such a level may indicate the integrity of the floodlight and the malfunction of the electrical network. A standard multimeter is used for measurement. The voltage output of this equipment must be 12 volts DC.

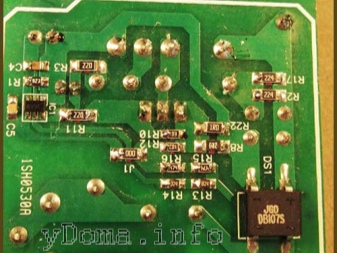

- If there is an output voltage, it is worth carefully examining the condition of the converter board, where, most likely, a breakdown lies. Defects can be found in contacts that oxidize and in tin plating that is cracked or burnt.

- If the diagnostics carried out did not give results, then it is necessary to perform a test for the operability of the matrix parts.

How to disassemble?

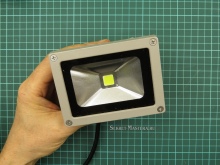

After carrying out diagnostic procedures and identifying the cause of the breakdown, you can start disassembling the floodlight. Do-it-yourself work can be done by a person who has basic knowledge of electrical engineering, and also has the skills to handle a soldering iron and a multimeter. The ability to read the circuits of the floodlight device will not interfere.

Disassembling an LED floodlight with glued glass should start directly from removing the glass, since the main parts are hidden behind it. More expensive models of floodlight structures are equipped with glass, which is fixed with bolts. Removing such a detail is not difficult.

Cheaper counterparts are equipped with glass, which is glued with a sealing compound to the reflex compartment. Dismantling the structure should begin with a careful cleaning of the sealant. This requires a sharp knife or small screwdriver. If the first method did not help to achieve the result, it is worthwhile to warm up the frame around the entire perimeter using a construction hair dryer. After that, the frame is pry off with an object that has a sharp edge.

Another way to remove glass in such models is to depressurize the luminaire using a screw located on the back of the floodlight. This part most often takes the form of a plug, which seals the space inside the structure. By unscrewing the screw, the pressure located inside the structure is almost equal to atmospheric pressure, and therefore methods with heating and prying the edges can give results.

After the glass has been removed, you can proceed with further repairs.

Replacing parts

If a broken wire fault is detected, no qualifications are required. The difficulty will be the need to troubleshoot the drivers, voltage converters, matrix or printed circuit board. Working with these parts requires highly specialized skills, as well as knowledge of diagnostic tools and a blowtorch.

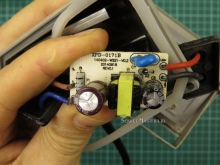

Current limiting capacitor

A breakdown in the current limiting capacitor manifests itself in uneven burning and flickering of the spotlight. The defect can be caused by the manufacturer's economy and the installation of a current limiter, which does not match the driver parts in its operational properties.

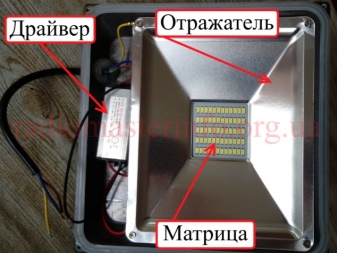

Power Supply

Failure of this element is a popular problem. Here you will need to find a similar part that can be purchased in a store or picked up in another device. Often, the power supply unit of the spotlight is changed to a similar part from the printer. If you want to purchase a new item, you should visit the store along with the old power supply unit so that the consultants can choose a model that is identical in technical characteristics. To remove the block, you will need to disassemble the searchlight.

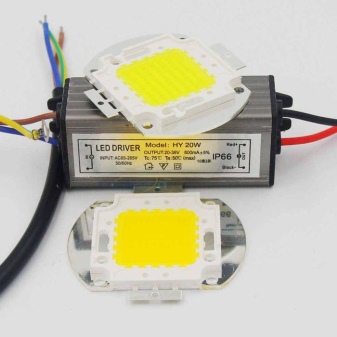

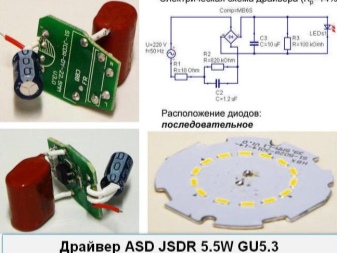

Driver

Low-power versions of floodlights often do not contain this element. They have a driver with LED characteristics installed. This element does not have the ability to draw power directly from the mains. It needs an alternating current, which is different from the mains supply. Therefore, a driver is used here. The driver carries out its activity taking into account the parameters of the operating temperature, as well as the time. The output current going to the LED elements is changed by the required value.

The driver is also repaired by disassembling the floodlight, since here it is also necessary to select an identical model.

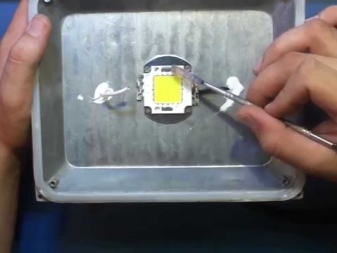

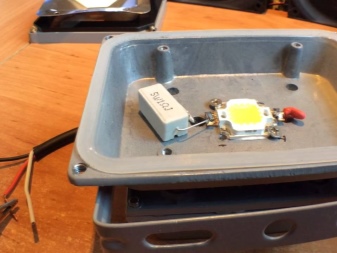

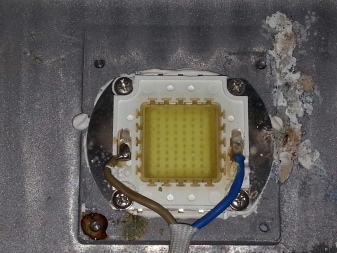

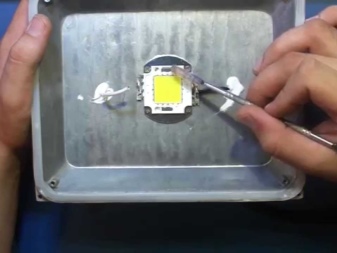

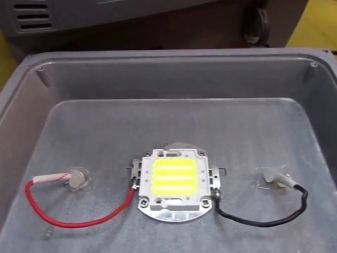

Matrix

Failure of matrix elements are also among the most common causes of malfunctioning of floodlight equipment. The defect appears when there is excessive heating of the matrix structure, after which the fuses blow out... In such cases, the searchlight is also disassembled and the faulty matrix is removed. To remove the part, it is necessary to unscrew the 4 screws and unsolder the conductive parts. After that, it is worth applying a small layer of thermal grease to the LED parts and soldering back the parts that conduct the current. After completing this work, you can screw the matrix part back.

It is not uncommon for the matrix wiring to be located in the substrate, passing through the hole. In this case, it is a matrix radiator. The transition between the links is covered with a layer of insulating material, which helps prevent short circuits on the case.

By replacing the die, the substrate and the place where the part will be installed are cleaned.

When working with a matrix, you should remember to maintain its shape and use native screws. This will allow not to violate the structure and significantly extend its service life.

It is better to repair matrix parts in the presence of several burned-out diodes, without waiting for the element to burn out in full. With the timely replacement of the matrix part, it is possible to preserve the operability of the driver and the conversion element.

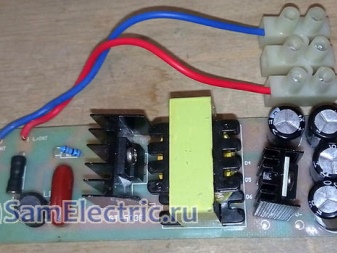

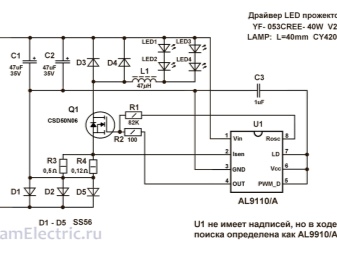

Voltage converter PCB

When diagnosing a printed circuit board, you can also find burned out elements, which will require repair work. Learning to read circuits on a printed circuit board will greatly simplify the process. Before starting work, the LED elements are ringing. Also, one of the legs of the board is unsoldered in order to get the correct result when making a call. If a malfunction is found, the burned-out parts are replaced with new elements.

Features of repairing models of different power

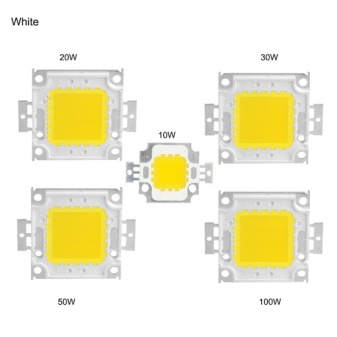

Equipment with a low power characteristic, for example, 10 watts, can be repaired after an external inspection. The same principle can be applied to floodlights rated at 30W, 50W or 100W. A close examination of the LED spotlight will help you to see the detachment in the protective coating, as well as the dark spots on the matrix responsible for the emission of light. It is possible to repair the matrix, where there is a diode emitter, but it will take a painstaking search for a similar element, which has a high price. The matrix most often has a cost that is up to 50% of the cost of the entire LED floodlight. It is also quite difficult to find an identical new matrix, since the LEDs are not characterized by the presence of markings.

To simplify this task, you can install the driver of a floodlight device with burned out parts on a structure that has a working matrix. If a burnt-out protective resistor is detected on the old driver, one can judge about a breakdown in the diode bridge, which is installed at the place of the transition between the key and control resistors. There are times when a replacement driver does not restore the functionality of the floodlight. Then you should conduct a more thorough check and identify possible breaks in the optical pair of feedback. Installing new parts can be effective.

Repair work on powerful floodlights, which are used for outdoor space or industrial premises, require more painstaking diagnostics. This includes equipment of 100 or 200 watts. To detect problems, remove the back panel and perform a visual inspection. He pays special attention to radio components located on the printed circuit board. They are looking for items with carbon deposits, deformation or other damage. After that, the analysis of the printed circuit board, previously pulled out of the floodlight installation, is performed.

Often the problem lies in burnt resistors, which occurs due to the passage of a high current of 220 volts and holes in semiconductors and capacitor installations. The dialing procedure can also identify a fault in the FET. To repair these elements, you should solder the damaged parts and replace them with new ones.

Repair work on various types of floodlights requires special attention and basic electrical engineering skills. Any master who knows how to work with a soldering iron and a multimeter can cope with this task.

If you find it difficult to perform these works, it is better to seek help from specialists.

How to repair LED spotlights, see the video below.

The comment was sent successfully.