Classification and selection of welding wire

Welding works can be both automatic and semi-automatic and carried out with a variety of materials. In order for the result of the process to be successful, it makes sense to use a special welding wire.

What is it and what is it for?

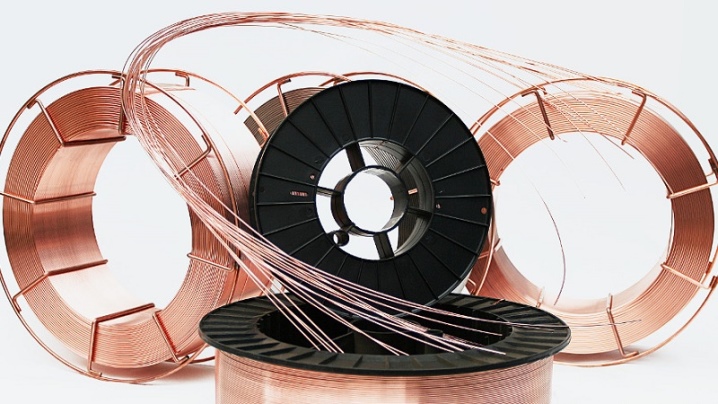

A filler wire is a metal filament, usually wound on a spool. The definition of this element indicates that it mainly contributes to the creation of stronger seams, free from pores and unevenness. The use of filament ensures production with a minimum amount of scrap, as well as with a low level of slag formation.

The device is fixed in the feeder, after which the wire is delivered to the welding area either in automatic or semi-automatic mode. In principle, it can also be fed manually by simply rolling out the coil.

The requirements for the filler material are not only related to quality, but also the suitability of the parts to be processed.

Species overview

The classification of welding wire is carried out depending on the characteristics, properties and tasks to be performed.

By appointment

In addition to general-purpose wires, there are also varieties for special welding conditions. As an option, the metal thread can be designed for a procedure with a forced formation of a weld, for work under water or with the use of bath technology. In these cases, the wire must have either a special coating or a special chemical composition.

By structure

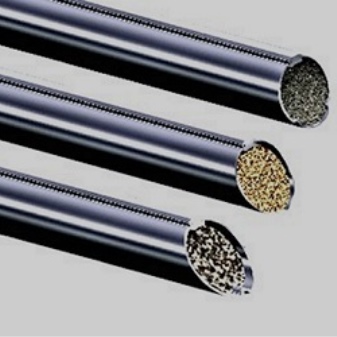

According to the structure of the wire, it is customary to distinguish solid, powder and activated varieties. Solid wire looks like a calibrated core fixed to spools or cassettes. Laying in rows in coils is also possible. Sometimes rods and strips are an alternative to such wire. This type is used for automatic and semi-automatic welding.

The flux cored wire looks like a hollow tube filled with flux. On the contrary, it should not be used on semiautomatic machines, since the thread pulling turns out to be difficult. Moreover, the action of the rollers should not transform the round tube into an oval one. The activated film is also a calibrated core, but with the addition of components used for flux-cored wires. For example, it may turn out to be a thin layer.

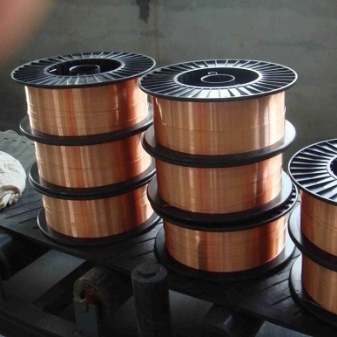

By surface type

The welding film can be copper-plated and non-copper-plated. Copper coated filaments improve arc stability. This happens because the properties of copper contribute to a better supply of current to the welding zone. In addition, the feed resistance is reduced. Non-copper-plated wire is cheaper, which is its main advantage.

However, the uncoated thread can have a polished surface, which makes it a kind of intermediate link between the two main varieties.

By composition

It is important that the chemical composition of the wire matches the composition of the materials to be processed. That's why in this classification, there are a large number of types of filler filament: steel, bronze, titanium or even alloyed, consisting of several elements.

By the number of alloying elements

Again, depending on the amount of alloying elements, the welding wire can be:

- low alloy - less than 2.5%;

- medium alloyed - from 2.5% to 10%;

- highly alloyed - more than 10%.

The more alloyed elements are in the composition, the better the characteristics of the wire are. Heat resistance, corrosion resistance and other indicators are improved.

By diameter

The wire diameter is selected depending on the thickness of the elements to be welded. The smaller the thickness, the smaller, respectively, the diameter should be. Depending on the diameter, the parameter for the magnitude of the welding current is also determined. Thus, with a given indicator of less than 200 amperes, it is necessary to prepare a welding wire with a diameter of 0.6, 0.8 or 1 millimeter. For a current that does not go beyond 200-350 amperes, a wire with a diameter of 1 or 1.2 millimeters is suitable. For currents from 400 to 500 amperes, diameters equal to 1.2 and 1.6 millimeters are required.

There is also a rule that a diameter of 0.3 to 1.6 millimeters is suitable for a partially automatic process carried out in a protective environment. A diameter ranging from 1.6 to 12 millimeters is suitable for creating a welding electrode. If the wire diameter is 2, 3, 4, 5 or 6 mm, then the filler material can be used for fluxing.

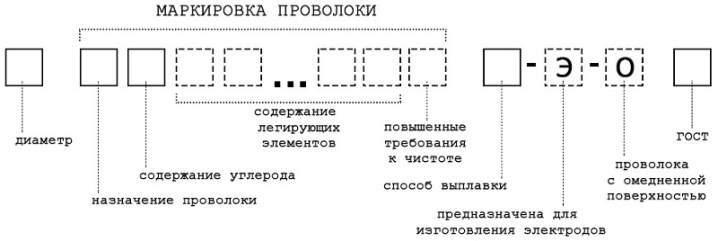

Marking

The marking of the welding wire is determined depending on the grade of the material that requires welding, as well as on the working conditions. It is designated in accordance with GOST and TU. For to understand how the decoding is carried out, you can consider an example of the wire brand Sv-06X19N9T, which is often used in electric welding, and therefore is very popular. The letter combination "Sv" indicates that the metal thread is intended only for welding.

The letters are followed by a number indicating the carbon content. The numbers "06" indicate that the carbon content is 0.06% of the total weight of the filler material. Further you can see what materials are included in the wire and in what quantity. In this case, it is "X19" - 19% chromium, "H9" - 9% nickel and "T" - titanium. Since there is no figure next to the titanium designation, this means that its amount is less than 1%.

Popular manufacturers

More than 70 brands of filler wire are produced in Russia. Bars trademark products are manufactured by Barsweld, which has been operating since 2008. The range includes stainless, copper, flux-cored, copper-plated and aluminum wires. The filler material is manufactured using innovative technologies. Another Russian manufacturer of metal threads is InterPro LLC. Production is carried out on Italian equipment using special imported lubricants.

Welding wire can also be manufactured at Russian enterprises:

- LLC SvarStroyMontazh;

- Sudislavl welding materials plant.

Chinese enterprises are widely represented in the filler material market. Their main advantage is the combination of average prices and good quality. For example, we are talking about the Chinese company Farina, which produces wires for working with carbon and low alloy steels. Other Chinese manufacturers include:

- Deka;

- Bizon;

- AlfaMag;

- Yichen.

How to choose?

When making the choice of filler material, it is necessary to take into account two basic rules. As already mentioned, it is important that the composition of the wire is as similar as possible to the composition of the parts to be welded. For example, for ferrous metals and copper alloys, different variations will be used. It is recommended to ensure that the composition is, if possible, free of sulfur and phosphorus, as well as rust, paint and any contamination.

The second rule is related to the melting point: for the filler material, it should be slightly lower than for the processed products. If the melting point of the wire turns out to be higher, then the parts will burn out. It is also worth making sure that the wire extends evenly and will be able to fill the seam completely.The diameter of the filler must correspond to the thickness of the metal to be welded.

By the way, the wire material must match the liner material.

Usage Tips

The storage of the filler wire cannot take place under high humidity conditions. The filler material in its original packaging can be stored at temperatures between 17 and 27 degrees, subject to a humidity level of 60%. If the temperature range rises to 27-37 degrees, then the maximum relative humidity, on the contrary, drops to 50%. Unpacked yarns can be used in a workshop for 14 days. However, the wire will need to be protected from dirt, dust and oil products. If welding is interrupted for more than 8 hours, the cassettes and reels will need to be protected with a plastic bag.

In addition, the use of filler material requires a preliminary calculation of the consumption rate. It is most convenient to plan the wire consumption per meter of the connection to be filled. This is done according to the formula N = G * K, where:

- N is the norm;

- G is the mass of the surfacing on the finished seam, one meter long;

- K is the correction factor, which is determined depending on the mass of the deposited material to the metal consumption required for welding.

To calculate G, you need to multiply F, y and L:

- F - means the cross-sectional area of the connection per one square meter;

- y - is responsible for the density of the material used to make the wire;

- instead of L, the number 1 is used, since the consumption rate is calculated per 1 meter.

Having calculated N, the indicator must be multiplied by K:

- for bottom welding, K equals 1;

- with vertical - 1.1;

- with partially vertical - 1.05;

- with the ceiling - 1.2.

It is worth mentioning, not wanting to carry out calculations according to the formula, on the Internet you can find a special calculator for the consumption of welding materials. The wire feeder usually consists of an electric motor, a gearbox and a system of feed and pressure rollers. You can do it yourself or buy a ready-made device. This mechanism is responsible for transporting the filler material to the welding zone.

It should also be noted that the wire for gas welding with acetylene must be free of rust or oil. The melting point must be either equal to or lower than the melting point of the material to be processed.

If it is impossible to find a welding wire of a suitable composition, in some cases it can be replaced with strips of material of the same grade as the material being processed. The requirements for metal filament for carbon dioxide welding are similar.

In the next video, you will find a comparative test of 0.8mm welding wire.

The comment was sent successfully.