How to crochet an armature?

The quality of the foundation determines how many years or decades the building will stand on it. Foundations have long ceased to be laid out using only stone, brick and cement. The best solution is reinforced concrete. In this case, a reinforcing cage is placed in the formwork, where the concrete solution will be poured, which is a lattice structure of reinforcing rods tied with a knitting wire.

Peculiarities

It is better to knit the reinforcement in the frame, rather than weld it. The fact is that welded seams break at temperature fluctuations of concrete, and the wire has flexibility and toughness, therefore it easily tolerates several dozen seasonal cycles of freezing and heating. Welding, if performed, is done by a highly qualified specialist. but welding of fittings for such products is prohibited by the rules of SNiP, especially when erecting multi-storey new buildings.

No matter how high-quality and durable the welding is, several welds that have burst from overload can crack in the concrete.

As a result, the foundation will lead a little, and the floors will tilt after it. A modern new building is not the Leaning Tower of Pisa. The walls here should always correspond to the sheer vertical, and the interfloor floors and the subfloor of the foundation should always correspond to the earth's horizon.

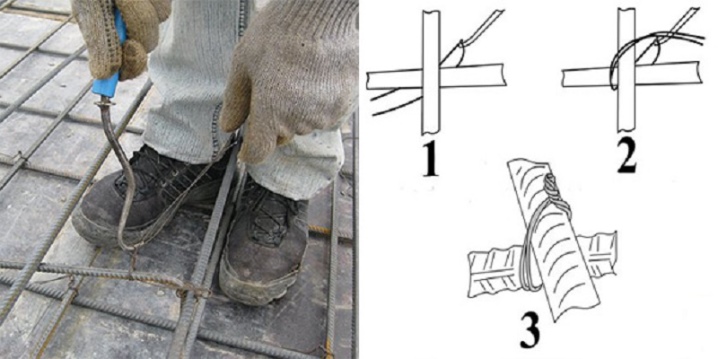

Hand knitting reinforcement with a hook is a tedious task. The tying of the reinforcement is mechanized using a knitting gun, screwdriver or drill, as well as changing the crochet hook. Alternative solutions: plastic clamps, ready-made metal brackets. But the latter methods are not suitable for complex (not only cruciform) connections. For example, plastic lengthens and stretches when overheated, and this leads to the fact that it tears easily in the cold.

Use reinforcement with a ribbed surface - the rods catch each other with protrusions even with the slightest tightening.

It is important that the joint can withstand the weight of the rod, multiplied several times.

Reliability of the connection is required only when pouring concrete. When the finished foundation finally hardens and gains strength, the rods will be held in the concrete due to its mechanical resistance, as well as due to the existing bulges and depressions at the joining points.

The ways

It is possible to tie the reinforcement with wire using a number of well-known tools and devices. Let's list them.

- Special pistol. He gets the job done quickly. However, this tool is quite expensive: it costs about $ 1,000. But with him it is impossible to approach the inner pins of the wide and high frame of the foundation. It is convenient to work with this device only at the extreme points of the frame.

- Crochet hook. It is used as a hand tool, in the handle of which a ball bearing is installed for ease of rotation, and a semi-automatic tool inserted into the chuck of a drill or screwdriver.

- Pliers or pliers. When using them, no additional tools are required. But they are not very convenient in the process of securing the wire.

- Nail. It is better to bend it into a crochet hook. This device is threaded between the double bent wire and the armature and twisted until the wire is tightened like a tourniquet to stop bleeding. If there is no suitable nail, you can use a Phillips screwdriver or a piece of thin smooth reinforcement (up to 5 mm thick).

Whichever tool is used, the properties of the wire should be the same - low-carbon steel is used, which is close in softness to ordinary metal without any additives.

You can soften any steel by calcining it red hot and then letting it cool under normal conditions.

If there is no opportunity or desire to purchase a ready-made knitting wire, then you can burn any old tire, after which only steel wire of the required softness will remain. But the burned-out steel partially turns into scale, becomes thinner and more brittle, so this solution is an extreme option.

Hook selection

The following factors influence the choice of a crochet hook for knitting reinforcement.

- The remoteness of construction shops and household markets, where you can buy a ready-made industrial hook. In many cases, it is made from a large nail (with a working pin diameter of up to 5 and a length of 100 mm). The hook should be long enough for the knitting wire to twist more easily. The longer the lever, the easier it is to wind it.

- Unwillingness or inability to incur unnecessary expenses. There is no need to purchase a tool made of low-quality steel, which breaks in several tens or a couple of hundred uses, if a high-quality analogue is not found. This does not only apply to hooks.

- The desire and ability to get out of numerous small difficulties on their own. If you don't want to stretch the construction for extra hours and days, buying a ready-made device is considered a quick option.

- Product performance. If the construction process, for example, the arrangement of foundations, is a permanent duty of the master (and not a rarely solved matter), then it is recommended to purchase a high-quality knitting crochet hook. Such a tool will last ten years, or even more. The best material is hardened tool steel or stainless steel. A slightly worse option is considered to be tool steel with the addition of chromium, molybdenum, cobalt and other additives. It is not recommended to purchase products from low carbon alloy steel.

Having purchased or made a knitting tool and the wire itself, you can start tying the reinforcement for the frame.

Step-by-step instruction

You can quickly and correctly fix the reinforcement using a thin (0.8-1.2 mm diameter) wire. A beginner master can do this in one of three possible ways.

Method one

- Bend a piece of wire in half.

- Measure a third of the length from the fold and fold it in half again.

- Throw the wire so that there is a loop on one side and two ends on the other.

- Insert the hook into the loop, hold it with your other hand, and pull the loose ends slightly.

- Rotate the hook. Hook it onto the risers and twist it a few turns.

- Fold over the excess.

Method two

- Bend a piece of wire in half, wrap with it the reinforcement connections from the bottom side.

- Hook the loop, insert the free ends into the hook.

- Twist until the armature is firmly secured in place.

Method three

- Bend a piece of wire in half, circle it at the joint along an oblique line.

- Thread the hook through the loop and pull the wire.

- Bend the other end at the bend point of the hook.

- Pull and rotate the hook.

The last of these methods can significantly increase the speed and quality of the binding of the reinforcement. This skill is developed quickly and easily.

The knitting wire must be twisted twice, or better - four times. Do not skimp on it: a reliable and high-strength connection of reinforcing rods and a high-strength foundation is worth it.

How to crochet reinforcement, see below.

The comment was sent successfully.