All about wire bending

Wire bending is a demanded technological process, with the help of which it is possible to give the product the required shape. The procedure involves changing the configuration by compressing the inner metal fibers and stretching the outer layers. It is worth considering in more detail what the process is, and with the help of what equipment it is carried out.

Basic bending rules

Wire bending is easy. However, to achieve the best result, there are a few rules to keep in mind.

- Gloves made of thick fabric should be worn when performing the task and working with the tool to prevent injury.

- Only serviceable tools or automatic machines are suitable for work. Before you start bending metal, you should check the equipment for damage or deformation.

- If a vise is required for the operation, you should first make sure that the workpiece is securely fixed.

- Before starting work, it is necessary to align the position of the workpiece.

- If the actions with the tool are carried out with one hand, the other should be kept away from the place where you plan to make the fold. This is explained by the fact that pliers or other tool can break loose and injure the hand.

- It is not recommended to place heavy instruments on the edge of the working table during the procedure. Otherwise, when performing bending, they can be touched and dropped on their feet, which will result in injury.

Taking these rules into account will allow you to achieve a reliable result and avoid product defects or injuries if a sudden release of material occurs.

In addition, during the bending process, it is recommended to pay attention to the integrity of the wiring and the organization of grounding when it comes to the use of electrical machines. It should be noted that manual bending allows you to work with small amounts of materials. This is explained by the fact that the procedure has a high labor intensity, which adversely affects the state of the human body.

Equipment overview

For large volumes of work, various automatic metal bending machines are used. It is not necessary to apply only the manual method of reshaping the material. You can use machines or other machines that can increase productivity indicators. It is worth taking a closer look at the range of tools and techniques for bending wire.

For manual bending

Metal wire is in demand in everyday life. Mostly hand-held locksmith equipment is used to change the configuration. This allows you to achieve the following elements:

- clamps;

- brackets;

- hangers.

To achieve the desired result, you should use soft and flexible types of wire.

This will reduce the effort required for manual bending and will significantly speed up the process.

It is customary to use houses to change the shape of metal elements:

- round nose pliers;

- pliers;

- locksmith vice.

If the wire needs to be cut, you can use wire cutters or purchase special side cutters. Such a tool is sufficient to provide the required result for shaping the wire into the required shape. Difficulties arise when it becomes necessary to fold products of large diameters. To do this, you will need to purchase special devices. You can also make them yourself.

Machine tools

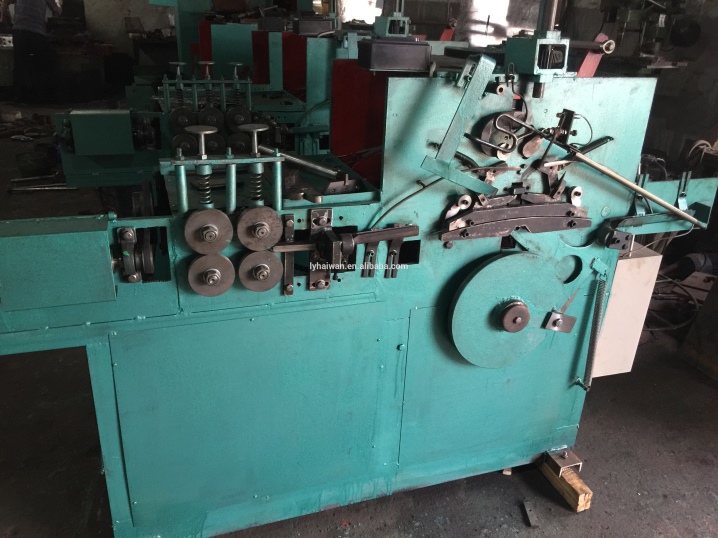

When it becomes necessary to make a large number of metal products from wire of different diameters, manual bending is out of the question. For the implementation of the operation, special equipment and special techniques are used. The bay method of changing the configuration of the metal is considered in demand. When using this technology, the following steps are performed.

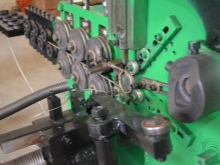

- The wire is wound on special coils and fed to a machine with rollers, in which two planes are additionally provided. They will ensure the alignment of the product.

- After that, the material is fed to the machine, which will form the required configuration of the product.

- The formed wire is cut off to begin the first step again.

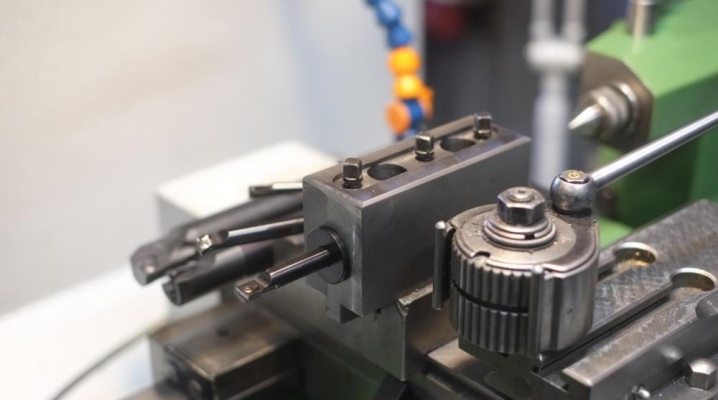

This process automates the bending procedure, which increases productivity. The wire bending machine is a static template. The design of the machine is provided with pressure rollers, which ensure the winding of the wire around the template. With the help of such devices, it is possible to achieve any configuration, as well as to ensure a bend of even the smallest radius. The latter cannot be provided by manual bending.

In some machines, special rollers are installed to facilitate the bending of products.

In such equipment, the principle of pushing the processed material is used to further change the shape. The end of the wire is connected to the wire before the operation. He pulls it through the rollers, which give the material the desired shape, set by the program. A separate machine is also used for wire alignment. The role of working bodies ensuring the achievement of the desired result can be:

- frames of the correct form;

- blocks with two planes.

The first ones are highly effective, therefore they are in demand in production, where a smooth and high-quality procedure is required. Modern technologies in the field of machine tool construction have made it possible to start the production of machines equipped with several bending consoles. This type of equipment is called CNC machine tools. They are designed for the production of flat and 3D products.

Wire bending with the use of such a figured technique allows increasing the productivity of factory capacities, as well as organizing the production of products of various shapes. To carry out the procedure, it is enough to set the necessary parameters in the program, the machine will independently cope with the task.

How to bend?

To bend small-diameter wire at home, you will need to find and prepare a vise, hammer, or pliers. but the use of the listed instruments requires a lot of time and effort to carry out the procedure.

If you want to speed up the process, you should think about making a more reliable device.

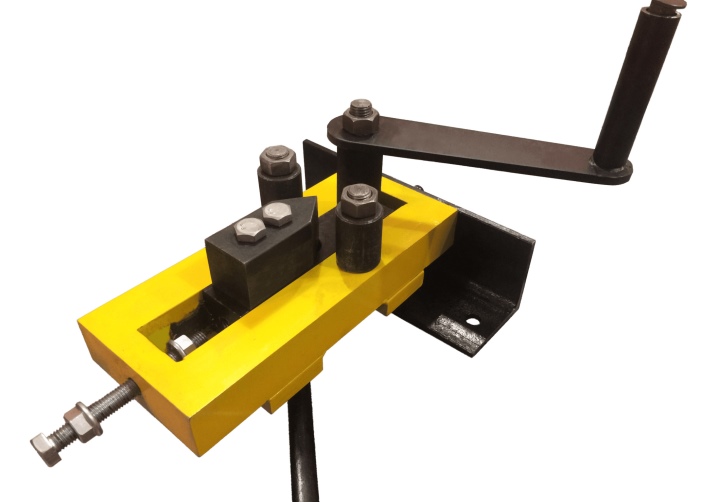

Such a tool is a manual rod bend, which will allow you to bend the wire. To make it you will need to take:

- two sections of a shaped pipe;

- grinder;

- welding machine.

The design of the rod bend includes a handle and a working part. To collect it, you will need to do the following.

- Cut the edge of a long piece at a 45 degree angle with a grinder.

- Cut a U-shaped part from the short part.

- Weld both elements together at a certain angle.

- Knock off the slag and clean the surface with a brush.

- Grind the tool.

When all the steps have been completed, the tool is ready to use. It can be painted if necessary. Working with a rod bend is not difficult. The device acts like a lever. To bend, insert the wire into the working part and press down on the handle.

The most popular question is how to make a ring out of wire with your own hands. To do this, you need to use a piece of wood of the required diameter or use a small piece of steel pipe.

In the case of a pipe, you will also need to select the required product diameter in advance.

When the required materials and workpieces are found or made, it is necessary to wind at least two turns of wire onto the template and make marks. After the performed techniques, it remains to remove the wire from the pipe or blank and weld an even ring according to the finished marks.

An overview of the wire bending machine in the video below.

The comment was sent successfully.