Description and varieties of steel wire

Steel wire is considered one of the most common metallic materials in the industry. It is at the same time the basis for the manufacture of a wide variety of items and at the same time can be used for independent use. There are many varieties of such wire - they will be discussed in our review.

Features and properties

In its most general form, the wire is metal flexible bar of metal, as a rule, cylindrical in shape. It is used to withstand increased mechanical stress, as well as transmit TV and audio signals and electricity. Steel wire can be solid, stranded, or braided. In most cases, it is performed with a rounded cross-section, a little less often it is made in square, hexagonal, rectangular and some other shapes.

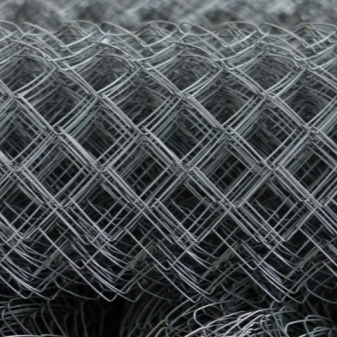

Steel wire belongs to the category of structural products, it is widely used in the production of steel cord products, steel ropes, metallized nets, springs, as well as various heating elements for electric furnaces. Hardware (nuts, bolts and rivets) are made of wire - in this case, the production is based on the cold heading technique.

The wire has rounded edges as standard. A similar tape is used in the manufacture of saws for wood and metal, as well as bushings, bicycle and motorcycle chains.

The main consumers of steel wire and goods made from it are such spheres as metalworking and mechanical engineering, the goods are purchased for the needs of the construction, chemical, petrochemical industries, ferrous and non-ferrous metallurgy. The most widespread wire is made of low-carbon steel alloy, it is a metallized long product with a low carbon content. Thanks to these technical properties, the product is obtained with increased strength in combination with good ductility.

If a zinc layer is additionally applied to a general-purpose steel wire, then it acquires resistance to corrosion. That's why galvanized wire is used in conditions of high humidity, while it retains its initial physical and operational characteristics for a long time. In accordance with the current GOST 3282-74, fired steel wire becomes softer.

This feature makes it possible to use it for carrying out reinforcing work, as well as include the product in the technological process for knitting reinforcement, packaging possible goods and producing various parts. The wire of the most general purpose is more in demand among all other types of wire.

Production

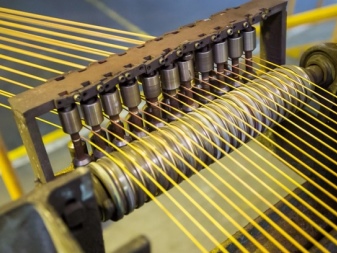

The release of steel wire is carried out by drawing wire rod on specialized equipment with further firing in a special furnace or without it.

The broaching and drawing process is not particularly difficult from a technical point of view. Compressed wire rod is used as a working raw material, all manipulations are performed on drawing machines. Compared to metal rolling, this operation has many advantages:

- automated machine operation provides increased performance;

- Drawing allows you to get products perfectly regular shape with a clean and leveled surface - due to this, the degree of subsequent processing is greatly reduced, and the wire itself acquires improved mechanical properties.

In general, the production of twisted steel wire involves several steps.

- At this stage, etching is performed, the main task is to remove the surface layer of metal and scale, which can interfere with drawing. Surface preparation is performed by degreasing, grinding, polishing and mechanical cutting of rejected areas. Since complex chemical compounds can be present in the scale, the wire rod is treated with acid solutions heated to 50 degrees. After that, the workpiece is washed and dried when heated to 75-100 degrees in special drying chambers.

- At this stage, there is heat treatment, the purpose of which is to make the metal workpiece softer, relieved of internal stresses. For this, the material is heated, kept for some time and cooled. As a result, the properties of steels change significantly and the wire drawing and firing process is facilitated.

- Further, with the help of a hammer, the steel billets are flattened and leveled. In this way, you can fix the metal on the drum of the drawing machine in order to pass it through the die.

- At this stage, directly drawing... For this, the processed and flat raw materials are drawn on the machine at the highest possible speed through a tapering channel. Depending on the amount of wire drawn, this process can be single or multi-strand.

- At the final stage, perform burning - the main task of these manipulations is to minimize the stress after drawing the metal. The steel becomes elastic, tensile-resistant and stiff, at the same time pliable to elongation and twisting, such parameters as resistivity and weight of 1 meter are improved.

There are two types of heat treatment.

- Light firing - performed in a furnace filled with inert gas. Due to this, the metal does not undergo oxidation, and scale does not form on it. Finished products acquire a light shade and a very impressive cost.

- Black firing - in this case, the simplest atmosphere is used, scale forms on the surface of the finished products, therefore it acquires a dark color. The cost of such wire is much lower than that of light wire.

Given that the steel alloy belongs to the category of metals that quickly corrodes, galvanizing is often included in the production cycle. The best and highest quality wire is produced using the hot-dip galvanizing technique, as this ensures maximum adhesion of the zinc directly to the wire.

The finished products at the exit are not afraid of rust and at the same time have an increased level of protection against such unfavorable external factors as the action of ultraviolet rays, wind and temperature fluctuations. In addition, galvanized steel wire is much more ductile than non-galvanized, and thus more durable. After that, the products are cut into pieces and marked.

In accordance with GOST 3282-74, steel wire is produced from steel in accordance with the current standard No.1050. Finished wire with a cross-section of 0.5 to 6 mm, which has not undergone heat treatment, at the exit must withstand at least 4 bends without violating the overall integrity and destruction of the metal structure. On the surface of a product not coated with zinc, technological standards allow the presence of small dents and scratches - while their depth should not be more than 1/4 of the size of the deviation of finished products in diameter. But the presence of all kinds of cracks, scales and films of any size is strictly not allowed.

Galvanized wire may have a slight whitish coating on the surface, as well as glitter - but only if they do not impair the overall quality of the coating.It is strictly forbidden to sell and use in the production process steel wire with unmetallic areas and black spots.

The coating should not crack and flake off, however, slight dust-like peeling is allowed.

Classification

By size and shape

Depending on the size and shape of the section, all finished products are conventionally divided into several groups. The first one includes the thinnest, the thickness of which is not more than 0.1 mm. Products with a cross-sectional parameter exceeding 8 mm are referred to the 9th group. All products, in accordance with the standards, are made in a round, square, as well as a multifaceted or shaped profile.

By type of finishing

Finishing the wire to a large extent provides the necessary mechanical and physicochemical parameters. That's why to give maximum strength, the wire is additionally hardened, fired and stabilized. The material that has not gone through these manipulations has a narrowly limited scope of use.

By surface type

Steel wire can be polished, etched, as well as polished or drawn as a result of preliminary turning and roughing. Wire release is allowed without any preliminary finishing. The coating can be metallic (copper-plated, brass-plated, galvanized or aluminized) or non-metallic (polymer or phosphated, in a PVC sheath).

Products without any coating are usually processed at high temperatures... Products processed in a thermal oven are produced in black or light shades, while its thickness can vary from 0.16 to 10 mm.

By chemical composition

Steel wire is made from:

- low carbon alloy with a carbon fraction of less than 0.25%, it is needed for reinforcing concrete products;

- carbon alloy with a carbon fraction of more than 0.25, it is used for the manufacture of springs, as well as wires and ropes.

Steel can be alloyed or high alloyed. Production from alloys with special physical and chemical parameters (heat-resistant, corrosion-resistant and precision) is allowed.

Certain design features impose special requirements on the alloy in terms of the content of chemical elements such as nickel and chromium.

By area of application

Depending on the field of application, the following groups of steel wire are distinguished.

- Stainless - made of special alloy with increased heat resistance parameters. This material is not susceptible to rust and oxidation, it is mainly used in the production of hardware products.

- Welding - It is produced with a cross-sectional size from 0.5 to 8 mm, mainly used for the installation of electric arc welding.

- Rebar - as the name suggests, such wire is widely used to strengthen reinforced concrete structures of all types. They can be without tension or under increased pressure. Due to the sections present in the steel material, maximum adhesion to the porous concrete base is ensured during the reinforcement process.

- Spring - comes into play when the springs are released, which are performed by the cold winding method, without subjecting them to further heat treatment.

- Cable car - relevant for the manufacture of sea, river and other ropes. Optimal for braiding cables, has found wide application in the field of their production.

- Knitting - made of low-carbon steel, characterized by increased ductility and at the same time strength. It is universally in demand in agriculture and construction.

Marking

Stalistaya has its own special marking, which includes a set of letters and numbers. So, steel black heat-treated wire with a cross-section of 0.86 mm is designated as follows: wire 0.86 - O - Ch - GOST 3281–74. A wire untreated in a thermal furnace with a cross-sectional area of 1.6 mm of the 2nd category with a galvanized coating of the 2nd class is marked: wire 1.46 - II - 2C - GOST 3281–74.

The wire is sold in spools, while the winding itself is performed without turns, laying it out in successive rows - thereby ensuring unimpeded unwinding.

One coil can contain up to 3 pieces, each coil should contain only one piece.

For information on how steel wire and steel cord are made, see the next video.

The comment was sent successfully.