Varieties and purpose of barbed wire

Not all inventions of human genius are equally enjoyable. But even the most "harsh" of them are sometimes necessary. For example, barbed wire is used in security, which is indispensable for warehouses, military facilities, and industrial production. Consider the varieties, options and methods of using this popular wire product.

Description

Any serially produced product is subject to special GOST. There is a state standard for barbed wire. It was approved back in 1969 to replace the hopelessly outdated standards of the 1941 edition. Barbed wire is classified by coating use and manufacturing accuracy. The largest dimensions of individual elements and permissible deviations for these indicators are strictly normalized.

The list of technical requirements established:

base material;

spike material;

the location of the thorns;

unacceptable metal defects;

features of various coatings;

surface density of coatings.

The state standard even says how long the barbed wire should be in one coil. According to GOST 285-69, one coil contains 380 running meters of clarified or galvanized barbed wire, and its weight is 35 kg (with a deviation of 2 kg up or down). But it's not that simple. Some sources indicate that more than 400 linear meters of wire can be in the bay.

A coil with a length of 100 m weighs about 9.1 kg, but the weight of one coil varies between 35-45 kg.

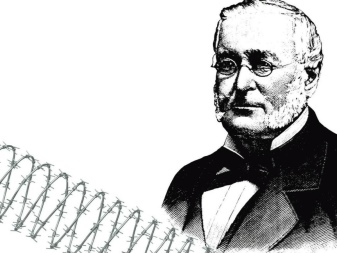

History of creation

It is impossible to name just one name of the person who invented the barbed defense. But it is quite obvious that the weak holding ability of ordinary flat wire pushed to its creation. It can hardly be seen as a serious barrier for animals in pastures or for criminals in prisons. In 1872, an American farmer G. Rose I came up with the idea of attaching boards with sharpened wires to a simple wire fence. The patent was received about six months later.

But the modern look of barbed wire was created Joseph Glidden. He realized that fastening sharp elements on the boards was irrational, so he created a metal structure, which, without additional devices, became a serious obstacle. Wrapping them with metal wire without sharpness helped to prevent the displacement of the spikes. Important: Glidden did not create his design from scratch, but proceeded from the already known samples, including those proposed in France.

One way or another, but the production of "egoza" grew rapidly: in the USA alone in 1875 it was made 270 tons, and a quarter of a century later production exceeded 150 thousand tons.

Barbed wire owes much to J. Gates. For the first time in the United States, he widely used advanced methods of metal melting, which made it possible to reduce the cost of production. And it was also Gates who ran an advertising campaign showing that dozens of cows are securely held by a wire fence. The cheapening of the finished product and bright marketing did their job - soon the "thorn" was bought not only by those who were looking for an effective replacement for the wooden fence around their home. They began to use it where the abundance of forests made it possible to build traditional corrals, because it turned out to be easier and more profitable.

Main types

There are two main types of barbed wire. Let's consider them in more detail.

Galvanized

For all the external similarity, modern barbed wire is not exactly the one that was patented at the end of the 19th century. By now, about 450 patents have been issued for it. Collectors of wire fences (there are, it turns out, there are some) count up to 2 thousand different types and samples. In the catalogs of manufacturers, only 2 dozen main varieties are often mentioned. The simplest option is a single-core corrugated construction with spikes throughout.

The thickness of such a product is most often 2.8 mm. It is this option that is usually used in summer cottages and fences around private houses.

Reinforced wire tape is also quite widespread. Its edges are almost as sharp as quality razor blades. The tape is available in straight or twisted versions.

Reinforced

Coating with a protective zinc layer does not always help to solve the assigned tasks. Sometimes a more significant strengthening of the enclosing structure is required. Such options are known:

- Bruno's spiral (turns of different diameters);

- flat corrugated tape with a pointed edge;

- "Chain-link" with diamond-shaped cells;

- spikes that complement the main fence.

A biaxial (more precisely, two-base) barbed barrier is also in demand. For the most part, it is made of galvanized metal.

The cross-section of each core reaches 1.6 mm. The veins are intertwined. Leading suppliers can deliver such wire in coils up to 100 running meters.

A typical barbed wire texture looks like this.

Products operating under voltage must be rated for a current of 2-10 kV. They are mainly produced for cattle breeding and penitentiary institutions. Returning to tape structures, it is worth pointing out that they can damage significant areas of soft tissue. They are used to protect structures, including those mounted on frames and supports. And the classic type of barbed wire is used mainly on its own.

The traditional version is often referred to as "thread"... It is always a galvanized material with a thickness of 2.5 to 2.8 mm. Going beyond these limits is strongly discouraged. There are threads both from one wire and from two strands, braided into a "pigtail". This distinction is also made between the thorns. Stamped studs are mainly used where the maximum degree of protection is needed.

The elastic "thread" is relatively strong and has a small cross section. Such material is more resistant to the negative effects of temperature extremes. Resistance to mechanical stress is also increased. As a result, "threads" with increased elasticity are used for the construction of large spans. As for the "soft" wire, it is much more convenient when fastening.

However, over time, such a fence weakens and begins to sag intensively. This disadvantage is especially pronounced with a significant length of spans. The problem is not too significant if you mount the wire in small areas. In addition, technologists distinguish piercing-cutting tape and reinforced "twist" in a special category. All the rest, experts consider them to be only subspecies of the three main types of barbed wire.

Popular manufacturers

The "thorn" is in demand brand "Egoza". This enterprise manufactures its products in the city of Miass in the immediate vicinity of the Ural federal highway. This location immediately creates an impressive logistical advantage. The main workshop was equipped with two automated lines, and the products are painted with a powder-polymer composition. Hot zinc coating is available upon customer's request; the thickness of its layer can vary from 70 to 120 microns.

It is worth paying attention to the production in the city of Lyudinovo, Kaluga region. From there you can order barbed wire in the versions SBB, AKL, PKLZ. "Mesh and Wire Plant" has been engaged in the production of AKL since 2006. The assortment also includes:

- Bruno's spiral;

- SCL;

- galvanized sharp wire with a diameter of 2.8 mm;

- flat "Gyurza";

- flattened barbed tape "Acacia" (and a number of other options).

You can also take a closer look at the products:

- PAO TNMK;

- MMK-Metiz;

- Atlant-Media LLC;

- ROL-MET-BUD;

- Eurobarb Concertina;

- SE "Soyuz";

- Granza.

Where is it installed?

Barbed wire can often be seen on top of fences around summer cottages, a country house or even a city house. But it is still actively used for fences around pastures, corrals. And also the barbed wire is mounted:

- around prisons;

- at military facilities;

- at train stations and stations;

- at airports;

- at service aerodromes;

- in warehouses;

- at retail outlets;

- at industrial enterprises;

- in ports.

Installation rules

Fastening of vertical supports, dug into the ground, is carried out in increments of no more than 3 m. These supports are quite enough for mounting the wire itself, nothing else is required. But an increase in the degree of protection is possible only with additional tension of the wire in the transverse plane with respect to the main strip. The barbed thread can be used in addition to the already created protective structures. In this case, it is mounted on top of fences and gates.

Reinforced tape is much more difficult to assemble. To install it you will need:

- scissors for cutting metal reinforcement;

- Grinder;

- some other tools, depending on how the wire is attached to the anchor points.

Egoza wire installation will be simplified by using special brackets. For flat and spiral models, the same type of brackets can be used. It is permissible to mount them in a variety of places. Now they sell crumbs of different formats:

- direct;

- L-shaped;

- Y-shaped.

The fence should be prepared independently with a step between the brackets of no more than 2.5-3 m. You need to work not only in protective gloves, but also in tight clothing. Sometimes it makes sense to even wear safety glasses. The shape of the bracket is selected taking into account the ease of installation. Before starting work, the area should be marked out.

Anchor points are fixed using bolts or by welding. Then a spiral is mounted on top of the crumbs using special brackets. The next step is to pull the double string along the entire length of the spiral. The spiral itself is aligned, and it is fixed using twists of a special pattern.

Finally, the individual parts of the wire fence are connected using mounting brackets. If the fence will be energized, you must warn about this by hanging special signs around the perimeter with clear warning text.

For the production of barbed wire, see the video below.

The comment was sent successfully.