Choosing a galvanized knitting wire

A wire is a long thread made of metal, more precisely, a long product in the form of a cord or thread. The section is not necessarily round, it can be trapezoidal, square, triangular, oval, and even hexagonal. Thickness varies from a few microns to several centimeters.

Various metals are used in the manufacture, as well as alloys from several types of metals. It can be cast iron, titanium, zinc, steel, aluminum, copper. As wide as the field of application of wire in industry is, so varied are the types of wire products.

Peculiarities

Knitting wire is a general purpose wire. In addition to construction, the scope of its application is unusually wide. These are household needs and rural industry. Summer cottages, personal subsidiary plots, estates on the ground, landscape design - knitting wire is required everywhere.

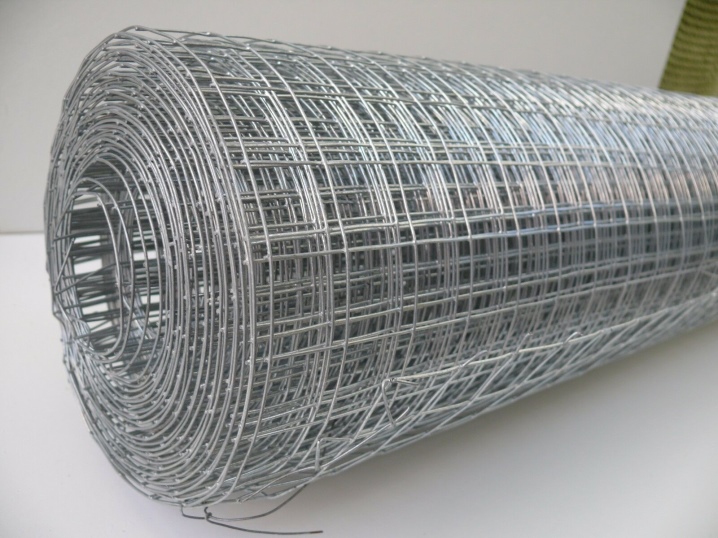

They make a netting, metal ropes, barbed wire from it.

A "bundle" is made of low-carbon steel, and wire rod is obtained by cold drawing. The next step in the technological process is heat treatment: annealing. The wire rod is heated and then slowly cooled in special ovens. This method restores the crystal lattice of steel damaged during drawing, the product becomes flexible, strong and loses residual stress in the metal.

Views

After annealing, the tying wire becomes convenient for knitting knots while fastening reinforcement and other parts. For fittings, 2 types of annealing are used: light and dark. Despite the external differences, there are no differences in technical properties between the types of annealing.

Such a wire has a low cost, but it does not differ in durability.

The galvanized type has excellent anti-corrosion properties, it is not afraid of precipitation, and its long service life allows it to be used in open areas. There is a kind of knitting wire produced specifically for fastening fittings: "Kazachka". It is sold in ready-made pieces, which allows you to significantly save time on blanks for tying.

All types of knitting wire, its sizes, types, nomenclature specifics are regulated by GOST 3282-74:

- products that have undergone heat treatment are marked with the letter "O" and are divided according to their resistance to rupture into subgroups I and II;

- the smooth surface is marked "B", the changing profile - "BP";

- marking "C" means bright annealing, "Ch" - dark annealing;

- the galvanized type is divided into classes: "1C" - a thinner layer of zinc coating, "2C" - a thicker layer;

- "P" marking means increased manufacturing accuracy.

Knitting wires 2 and 3 mm are used in agriculture and for fastening large diameter reinforcement bars.

Which one to choose?

For construction, types are chosen, guided by the diameter of the bar: the thicker the reinforcement, the larger the diameter of the section will be needed. For bars of the most demanded reinforcement of 8–12 mm, product thicknesses of 1.2 mm and 2.4 mm are used. The optimum size is characterized by suitable load strength and good knot elasticity.

For frames that are to be subjected to increased mechanical and atmospheric stress, choose a product made of low-alloy steel with light or dark galvanized with a diameter of 3 millimeters or more. If it is intended to be used in open areas, then a galvanized or polymer coating should be chosen. For tying grapes and installing trellises, knitting wires of 2 and 3 mm are also used.

Usage Tips

To calculate the required amount of knitting wire for tying reinforcement, you can carry out simple calculations using the formula F = 2 x 3.14 x D / 2, where F is the length of the wire and D is the diameter of the reinforcement. By calculating the length of the required segment and multiplying the result by the number of nodes in the frame, you can get the required number.

It is estimated that 10 to 20 kg of wire are required per ton of reinforcing bars. To calculate the weight, you need to multiply the received footage by the specific gravity (mass of 1 m) of the wire.

The knitting pattern also affects the consumption: if in the center of the structure it is possible to knit knots through one (in a checkerboard pattern), then all the joints are tied around the edges. The diameter of the wire matters: the thinner it is, the more turns in the knot will be required.

For tying the reinforcement, special hooks are used: simple, screw and semi-automatic. Knitting pliers are not much different from a hook, but they have nippers in their design. The reversible pliers allow you to use the wire directly from the coil. The professional knotting gun has a high working speed: tying a knot takes less than one second, but it is a very expensive tool, and its use is justified in large-scale construction.

An overview of LIHTAR galvanized knitting wire in the video below.

The comment was sent successfully.