All about nichrome wire

Nichrome can be called a specific material, it is not as common as copper and iron, but it is no less important. This type of alloy was obtained back in 1905 by the works of the American scientist Marshal.

Features and properties

The main components of nichrome wire are chrome and nickel. It also contains additives such as silicon, iron, aluminum, manganese.

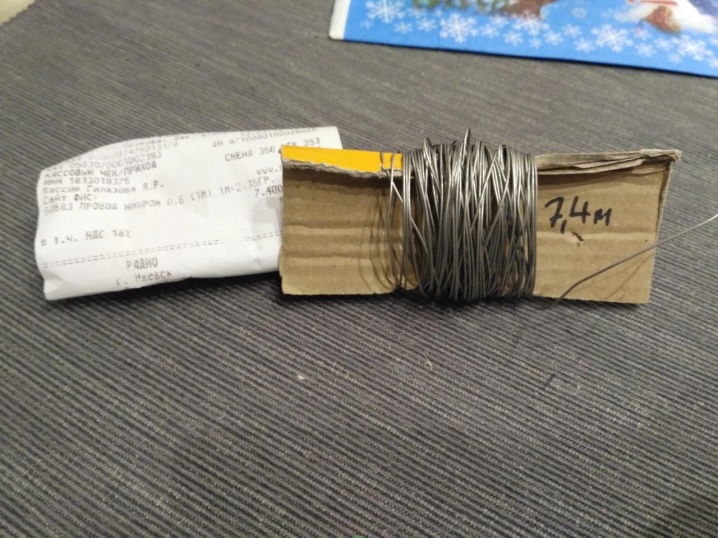

Various industries use nichrome wire in their work. It has the appearance of a silvery thread, the diameter of which can be from 0.1 to 7 millimeters.

Usually this type of product is sold in skeins, reels, if necessary, it is measured and cut off.

The main properties of nichrome can be found in the following table.

Options | Indicators |

Heating, melting temperature | 850 - 110 degrees Celsius |

Strength | 650 - 700 MPa |

Resistivity coefficient per meter | 1100-1140 ohm |

Density | Less than 8500 kg / m3 |

Nichrome has a low weight, due to this, the material is often used for the production of all kinds of electrical appliances. Wire does not suffer from loss of performance in liquids and corrosive environments. Thanks to chromium, a film forms on the material, which keeps it isolated from the negative effects of external factors. The properties of this alloy are described in detail in GOST 10994-74, GOST 8803-89, GOST 12766.1-90.

Let us mention the features due to which nichrome is considered a valuable metal.

- Does not rust, which distinguishes it from other similar materials.

- Has significant resistance to specific current. Due to this, nichrome wire is required much less than steel wire for the manufacture of any device. In addition, this feature contributes to the fact that objects made of nichrome are small in size and weigh little.

- Does not deform, does not burn under the influence of high temperature.

- It is characterized by elasticity, which allows you to easily change the shape of the wire.

Flaw the nichrome alloy has one - this is a high price, but it does not in any way reduce the demand for this refractory material.

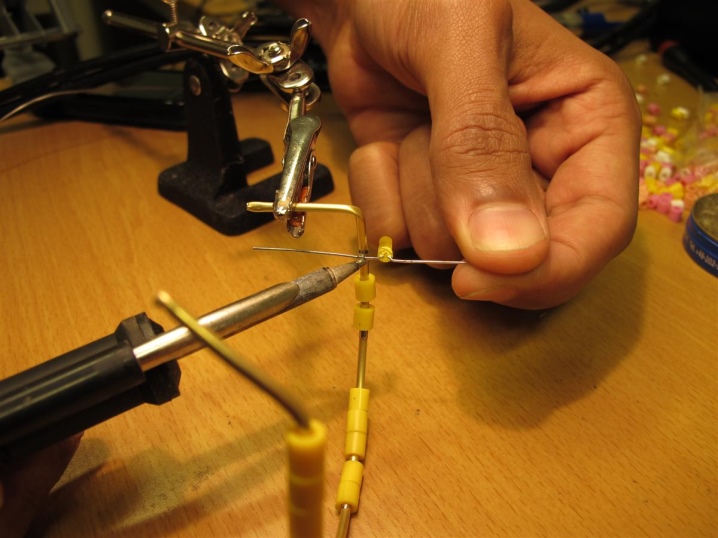

It is unable to create connections while applying the flux.... To carry out this procedure, you will need to follow a certain sequence of using soldering tools. Solder in this case can be a tin-lead alloy.

It is also worthwhile to separately prepare a flux, the component composition of which must be dosed in severity. The main components of the substance are petroleum jelly of technical origin, glycerin and zinc chloride. In order for the mixture to get the perfect consistency, you will need to thoroughly mix all of the above components. Sandpaper will need to eliminate the remnants of dirt and oxidized formations. After that, the area should be wiped with cotton wool, apply flux and solder.

Where is it used?

The use of nichrome thread is observed in many areas of life and production. For example, many people know that a spiral of an electric stove and heaters in a boiler are made of it. Also, without nichrome, it is difficult to imagine burning, cutting wood and the tool itself - a burner.

In the industrial field

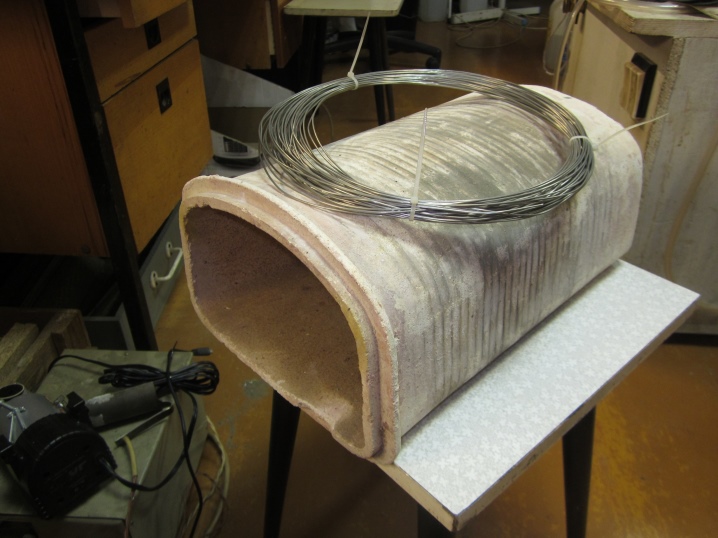

The metal industry is one of the leading places in the life of mankind.Its products are widely applicable in the direction that uses electric heating furnaces, kilns for roasting, drying, as well as units that are heated to a high temperature regime, devices that are exposed to heat.

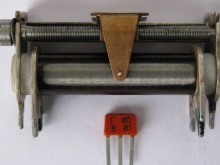

Nichrome wire is an integral part of an apparatus for welding, a household heater, a glass heating system, as well as a resistor, a resistance unit, and a rheostat.

Due to the high resistance of the alloy, it is used in the following areas:

- thermocouple heating plate in metallurgy;

- industrial type ventilation dryer;

- parts of the boiler, heat exchanger;

- electrodes for welding;

- wires.

In the household sphere

In domestic conditions, nichrome is used for foam and polystyrene foam cutting. As you know, at home, cutting these materials is rather difficult, since the foam can crumble from the use of an ordinary knife. The wire is used to make a special machine that works on the basis of a heated string. Using this device, you can independently make various blanks from expanded polystyrene and polystyrene foam. Nichrome is a structural element in most household appliances:

- Heating elements for kettles, boilers, boilers;

- elements of hair dryers, flatware, irons;

- car candles, as well as their heating system;

- electronic cigars.

In medicine

Nichrome threads are necessary in the medical field, because they are not capable of causing an allergic reaction in the body. Studies have shown that cuts that have been sutured with nichrome threads heal faster than others.

In addition, such elements have found their application in the plastic direction of surgery during intracavitary surgery.

In institutes of pharmacology, the alloy is part of the heating device for the heating mantle.

Marking

Nichrome wire has more than one brand, therefore each type of product has certain quality characteristics. The main groups of nichrome are as follows.

- Resistor.

- The material is found in the construction of household and industrial heating elements. The group has high heat-resistant capabilities.

- A group of nichrome, designed to work with high temperatures up to 9 hundred degrees.

The wire of the resistor group is characterized by a diameter of 0.009-0.4 millimeters.

This indicator for the second group of metal can be from 0.2 to 7.5 millimeters. The "relatives" of the alloy wire include kanthal and fechrali, which look like a chrome alloy with iron and aluminum.

These materials are characterized by high electrical resistance, resistance to temperature conditions up to 1400 degrees Celsius. Despite all of the above advantages, kanthal and fehrali are not as reliable as nichrome, but they are much cheaper.

Nichrome products have a different percentage of the constituent parts. The most common are the following.

- X20N73YUM melted by vacuum-induction method and as constituent elements contains the following proportions of substances: 20% chromium, 73% nickel, 3% aluminum, 1.5% molybdenum.

- KhN70Yu-N consists of 20% chromium, 70% nickel, 3% aluminum, less than 0.3% manganese, less than 1.5% iron. This alloy is often used for the production of elements that are an integral part of heating devices.

- KhN20YUS used in industrial furnaces with a heating function. The alloy contains 20% chromium and nickel, 1% aluminum, and 50% iron.

When buying nichrome, you should take into account the marking:

- H - category of heating elements;

- C - used in elements of resistance;

- Heating element - for boilers with a tubular type of construction.

How to determine?

Outwardly, nichrome wire looks like many other products, so it is important for each consumer to learn how to distinguish it from another. The main distinguishing features of corrosion-resistant nichrome:

- the new metal is white, and the used metal darkens;

- the magnetism of the wire is minimal or completely absent;

- nichrome is a rather tough material;

- acids can destroy this metal;

- products do not oxidize if exposed to high temperatures.

To select a nichrome alloy wire, you will need to properly analyze its rated performance.

For this count specific resistance of the working element according to the formula R = ρ l / S, where length, cross-sectional area is taken into account.

Where to get?

Many are interested in how and where to get nichrome at home. There are methods to find metal.

- Place an order for nichrome products in the company that manufactures them.

- Buy from a hardware store or hardware store. This can be the point of implementation of radio components, various materials and constructors.

- Buy from people who are engaged in the implementation of radio components and small things made of metal.

- In my house. Nichrome is found in some devices, for example, in the spiral of an electric stove.

For a large order, it is better to use the first option, all the rest are suitable if the consumer needs a little nichrome alloy.

What can be replaced?

Failure of the heating element of various household appliances is currently not uncommon. Often, equipment needs to change the working spiral, which is considered an integral part of an electric stove, iron, kettle. In this case, stainless steel is considered a worthy alternative to nichrome wire.

These materials have almost the same resistance. However, it is worth remembering that stainless steel has low resistance to the oxidation process. To replace the nichrome alloy, you can use the braid from the old hose, where there are reinforced stainless fibers. Nichrome is a unique high performance metal, so it is quite in demand nowadays.

Where you can get nichrome wire, see below.

The comment was sent successfully.