All About Stainless Welding Wire

Welding is a convenient and high-quality way of joining surfaces and products made of various metals and their alloys. However, this difficult procedure requires special equipment and materials. A welder, in addition to a welding unit, wires with a holder or a torch, electrodes and protective equipment, during work cannot do without a filler wire, for example, stainless, which has proven itself well in carrying out particularly complex and demanding welding work.

Features and purpose

Stainless welding wire is a consumable filler material. It is widespread not so much in the domestic sphere as in construction and industry. Chemical, oil and food production cannot do without this consumable. Stainless steel wire for welding is necessary when creating all kinds of industrial structures, parts, as well as when repairing old equipment and structures.

It is made in accordance with GOST, which guarantees the high quality of the product, as well as a good result of its use. This wire is used as a consumable during automatic and semi-automatic welding. It can be continuous, requiring, when used in the welding process, gas protection by means of CO2, argon or their combinations.

In gas-free protection, flux-cored stainless wire has found its application, which has the form of a tube with a flux and a gas composition inside. Internal filling of the wire is necessary to protect the resulting weld.

This product has found its application as a surfacing consumable. As a result of its use, a protective film is formed on the surface, which protects the weld from corrosion. And also stainless wire is the basis for the preparation of electrodes. The welding process using this material is carried out by artificially raising the temperature to the value required for melting.

The filler material is melted due to the presence of unique components in it. During welding, the wire, having melted, does not spray, but evenly fills the seams, making them strong and neat. Nowadays, it is rare to find a welding process that does not use this type of wire.

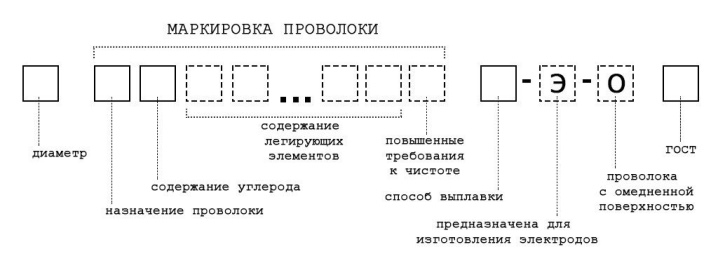

Decoding of marking

Stainless welding wire is designated in the same way as alloyed. The only difference can be called the presence of chrome and nickel in large quantities in stainless steel. Solid stainless wire is marked in accordance with GOST 2246-70.

The designation may contain the following letters:

- A - the wire contains a standard amount of phosphorus and sulfur;

- AA - the above substances are contained in a reduced amount;

- NS - the product was produced by electroslag remelting;

- NS - the wire is used to prepare the electrodes;

- O - there is a copper coating on the surface of the product, therefore the wire is used in the case of making critical connections with a stable arc.

According to GOST standards, the marking of steel wire may contain the following designations:

- NS - cold rolled product;

- T - thermally processed;

- NS - increased production accuracy;

- TS - metal of light color, in which there are no oxides.

Depending on the diameter, 100 m of stainless steel wire for welding has the following weights:

- 0.5 mm - 0.31 kg;

- 1 mm - 0.62 kg;

- 1.5 mm - 1.4 kg;

- 2 mm - 2, 48 kg.

Popular brands

There is a wide range of grades of stainless welding wire on the market today. Therefore, when choosing this product, you should pay attention to the composition. It often contains combustion and oxidation stabilizers. A manganese-containing product is characterized by density, and a carbon-containing one - by low plasticity. The choice of wire should be based on the characteristics of the future application.

Among the most popular brands of wire for stainless steel are the following:

- 12X18H10T;

- Sv 07x25n13;

- Sv 06x19n9t;

- Sv 04h19n11m3.

Top manufacturers

The cost of stainless welding wire is directly influenced not only by the quality of the material, the presence of impurities, but also by the specifics of production. This filler consumable is made in many European countries, including Ukraine and Russia. Currently on the market you can buy a product from the following manufacturers:

- "SpetsElektrod";

- Ecom Plus;

- Sychevsky Electrode Plant;

- "Vadis-M";

- Frunze - Electrode;

- Lincoln Electric;

- "Oliver";

- ESAB.

Usage Tips

To get a good connection, many welders use semi-automatic when working with stainless wire. This equipment protects the seams from extraneous influences, automatically feeds the filler wire to the welding place, forcibly cools, and can be used in hard-to-reach places.

Before doing the work, it is worth doing the preparatory stage, that is, to perform a number of activities.

- Eliminate contamination from the treated surface.

- Degrease the weld on the workpieces.

- Remove excess moisture from surfaces by heating them to 100 degrees.

In order to obtain a small transitional seam thickness between the parts to be welded, you can use several welding methods:

- short arc method;

- inkjet transfer;

- universal impulse method.

To achieve a high-quality result of working with a stainless additive, the welder will need to fulfill the following requirements:

- position the burner at a negative angle;

- drive the head at a distance of 1.2 cm from the metal surface;

- melting the wire should be done in small portions; large drops should not be used here.

Defects can sometimes be observed after welding. To eliminate them, it is necessary to warm up the parts with a burner and tap them with a hammer.

Welding stainless wire is an important attribute, without which it is difficult to imagine the welding process. Consumers can purchase this product in a skein, reel or coil. This universal type of raw material has high technological properties and therefore is used in many industries and construction.

For tips on choosing a wire for welding, see the following video.

The comment was sent successfully.