Features and purpose of brass wire

Sheets, plates and other large blocks of metal are not suitable everywhere. Often, for example, wire is made on its basis. All consumers definitely need to understand what are the features of brass wire, as well as know its intended purpose.

Description

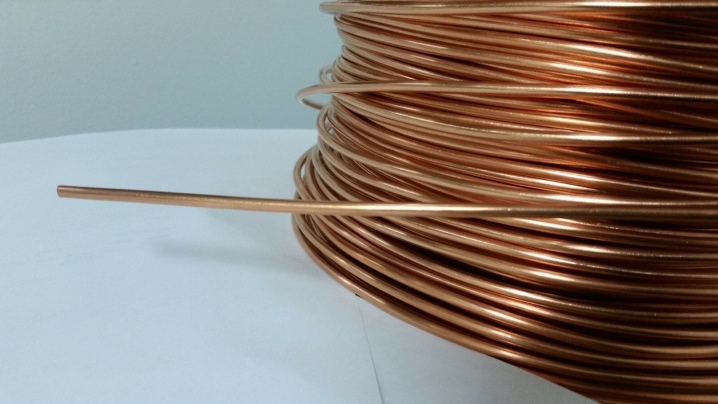

The wide popularity of brass wire can be explained very simply: it is a truly excellent material that satisfies even the most stringent consumer needs. Well-made brass has impressive corrosion resistance and is relatively mechanically strong.

To obtain it, a wide variety of alloys can be used.

The ductility of brass allows excellent transfer of deforming loads. The characteristic features of brass wire are:

- section constancy;

- increased physical and mechanical characteristics (in comparison with the copper analogue);

- the possibility of using a wide variety of additives that increase the overall performance.

Features of production

There are clear requirements of GOST, which must be met by any brass wire produced or sold in our country. This product must have a stable circular cross-section of 0.1 to 12 mm. In the production process, the following can be used:

- pressing;

- rental;

- drawing.

Brass wire of the general category is made in accordance with GOST 1066-90. Alloys L63 and Ls59-1 are used for it. The list of tests and the procedure for obtaining test samples is subject to GOST 24231, which appeared back in 1980. Finished products have unmeasured lengths and an etched surface. Delivery can be in the form of coils, coils or spools.

It is customary to distinguish semi-hard, soft and hard wire. There is also a distinction in terms of normal accuracy in relation to the diameter of the cross sections. At the end of the treatment, the residual surface tension is removed. For this purpose, either low-temperature processing (special firing mode) or mechanical processing is used.

Contamination and other defect that could interfere with the inspection of the surface are not allowed.

There should also not be:

- redness after etching;

- large layers of technological lubricant;

- severe blackouts;

- significant signs of discoloration.

The brass wire is marked with the alloy percentage and alloy grade. This product can be processed without problems in a hot and cold state. It is easy to bend and solder. Brass wire is not damaged under the influence of atmospheric factors and caustic substances. In addition, the workflow is also focused on enhancing its aesthetic properties.

Views

Universal brass wire of the LS-59 brand is created on the basis of zinc and copper. Lead is used as an alloying addition. Alloy type L63 is formed by 64% copper and 37% zinc. It is actively used as a solder in welding. Alloy L80, due to the increased concentration of copper, has excellent conductivity, and therefore it is widely used for the production of electrical equipment.

Wire made of L-OK alloy contains silicon and tin additives. This round thread is highly resistant to corrosion. With its help, it is easy to prevent the appearance of corrosion foci in the places of welded joints. Copper-zinc combination is used in LS-58 wire; lead is also added to it. Such a product is needed to produce contact pairs for electrical installations and automotive electronics.

Existing technological standards prescribe to produce only round cross-section welding wire. It is marked with the letter combination "KR". You can get wire for welding by cold drawing (designation "D") or hot pressing (designation "D"). When supplying a welding wire, other designations may also be used:

- low and high hardness (M and T, respectively);

- cuts on spools - CT;

- off-gauge length - ND;

- cores - CP;

- BR - delivery in drums;

- BT - shipment in coils and coils.

For semi-automatic welding, brass threads with a diameter of 0.3 to 12 mm are used. It is customary to divide the entire assortment into 17 standard sections. Mechanized welding is usually done with 2 mm wire. If the cross-section is 3 mm, 5 mm, then this is already an excellent option for working on automatic installations. But, of course, they also take into account the thickness of the metal and its properties.

Application

Brass wire is widely used in the production of electrical parts and decorative fixtures. With its help, contact pairs are formed in a variety of technological installations. But brass wire is also needed in filters used in the oil refining industry.

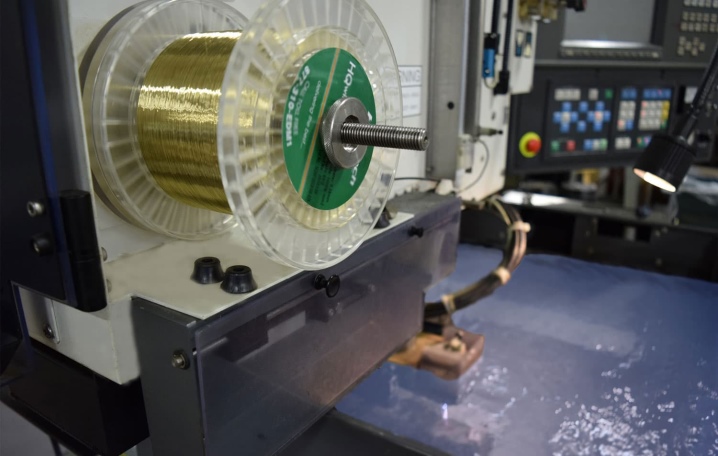

The basic version of this product is actively used for EDM machines in the process of highly accurate wire cutting.

Usually, such a material contains a strictly normalized amount of copper and zinc, otherwise it is impossible to maintain stable properties.

But the use of brass wire does not end there. It is often used as the basis for special filters in the food industry. Such blanks are also used to produce fine mesh nets, various parts and mechanisms for the shoe industry. Brass winding can be found in transformer cores. Also, a thread from this material is used in:

- sifting crushed substances;

- receiving fountain pens and brushes;

- making jewelry.

but the most popular product has been and remains filler wire for welding... Sometimes only its application provides a decent quality of the welded seam. Welding wire for semi-automatic, manual or fully automatic welding is different, but one thing remains unchanged - it actually replaces the electrodes.

The physical and chemical properties of the finished weld depend on the grade of the alloy used and on the correctness of its application. Professionals urge not to confuse the wire that replaces the electrodes and the one that goes into their production.

You can see a detailed overview of the types of wire for creativity in the next video.

The comment was sent successfully.