All about wire rods 6 mm

Wire rod (wire) is a metal rod with a round cross-section, made by hot rolling on a wire mill.

Description and characteristics

Wire rod 6 mm can be used as an independent material, this size is popular due to its technical properties and ease of processing. Used in construction and metalworking.

According to GOST standards, carbon steel grades St0, St1, St2, St3 can be used for manufacturing. If non-ferrous metals or their alloys are used for production, then the standards are set in accordance with TU.

The tolerance of deviations in the size of the diameter should not exceed –5% or + 5%, the amount of vasculature should not exceed 50%.

Continuous wire rod is packed into coils, the weight of which varies from 100 to 150 kilograms, but not more than one ton. Also, in various small-scale retail chains, it is possible to sell pieces of rolled metal or coils of less weight. The weight of 1 meter in kilograms is 0.222, this mass is an approximate reference value, it also depends on the material.

How is it produced?

Material processing, depending on what kind of raw material is used, can take place in several ways:

- hot rolled - carbon or alloy steel;

- cold rolling and pressing - to obtain a high-precision section;

- combined rolling with continuous casting - for non-ferrous metals and their alloys.

Wire production takes place on linear continuous or semi-continuous machines.

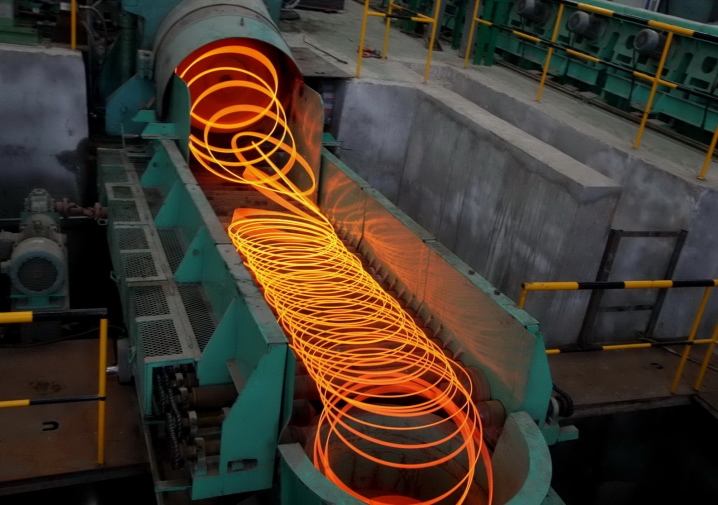

By the method of hot drawing, square-shaped metal billets with a section of 10x10 centimeters are driven through the shafts of the rolling mill. The bloom (metal) heats up during this process, and the shafts give it a circular cross-sectional shape. At the exit of the rolling mill there is a winding machine - it lays the still uncooled wire rod in rings.

The next process is cooling. It can take place in two ways.

- Cooling naturally (with the help of air). It happens slowly, but the wire rod is softer and more ductile as a result. Marked as BO.

- Accelerated cooling. For this, water or special fans are used, the material gets a harder and more durable surface. Marked with UO1 or UO2.

When buying, be sure to pay attention to which cooling method is indicated in the specifications.

After the metal has cooled, it is laid in bays.

The wire rod, from which the wire will be made in the future, undergoes an additional descaling process. This can be mechanical cleaning (with a descaling agent) or dry cleaning (etching in a special acid).

The quality of the material must meet increased requirements - no defects (burrs, sunsets, etc.) are allowed on the surface, as they reduce strength and other properties.

In terms of quality, wire rod can be of two types:

- class B - average accuracy;

- class B - increased accuracy.

Rolled 6 millimeters can also differ in hardness:

- soft - designed for flexible products such as wires, cables, etc .;

- semi-soft - for the manufacture of elastic products: springs, welding materials, ropes;

- solid - for materials with increased strength: drills, fasteners of massive structures, etc.

Species overview

Copper Rod made from molten copper by continuous casting, then rolled in mills. Has the designation MM. Divided into three classes: A, B, C.

Used for wires and cables capable of withstanding high loads.

Aluminum rolled metal Is a rod with a circular cross-section, which can have a diameter of 1 to 16 millimeters. It is used for the production of various cables and power wires. Production of wire rod from aluminum at a price will cost about 3 times cheaper than rolled metal from copper. Production takes place in two ways:

- from molten metal;

- using blank rollers.

Stainless wire rod is the most popular option with a section size of 8 millimeters.

It is used for grounding structures and for lightning rods.

Steel wire rod manufactured using hot rolled products. This type can be of two strength classes: C - standard, B - increased. Which of them the finished product will have is determined by the materials used and by the cooling method. Along the length of the entire rolled metal, deviations in the size of the diameter are unacceptable, and the coil must be twisted from a solid rod.

Steel wire rod is used for reinforcing concrete structures, as well as for the construction of load-bearing inter-apartment walls or walls.

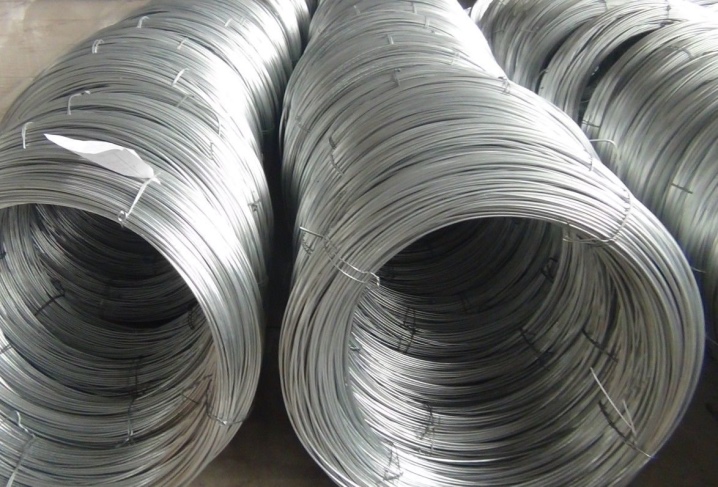

Galvanized wire rod - a fairly common type obtained by hot rolling. The size of the diameter varies from 5 to 10 millimeters. Carbon steels are used for manufacturing. The main feature of such rolled products is zinc coating.

Advantages:

- corrosion resistance;

- reliable and durable product;

- resistance to many loads: linear, dynamic and static;

- easy to process in a variety of ways (cut, stamp or bend);

- in comparison with other varieties it has a more aesthetic appearance.

Applications

Often people do not think about how much wire rod is in demand in life. So, by means of a steel billet, cargoes with large dimensions and weight are packed. Reinforcing frames are made from it, it is this element that strengthens the bearing parts of buildings and structures. Wire rod with diameters of 6 and 6.5 millimeters is used for the production of gratings for bundling brickwork.

The most commonly used sizes are 6 and 8 millimeters. This product size is best suited for grounding and lightning protection. It is also used as a raw material for the production of nails, springs, wires, welding machine diodes, cables and ropes.

It is actively used in the furniture industry, for the manufacture of various fasteners, furniture fittings or decor items. Wire rod is also widely used in automobile and machine tool manufacturing, shipbuilding, aviation and agriculture.

On the network you can find many tables where the mass, length, diameter of products and their ratio to each other are indicated.

When buying rolled metal products, it is imperative to look at the documents where all the necessary parameters and markings are indicated.

How to make a chain from 6 mm wire rod, see the video.

The comment was sent successfully.