Wire rod: what happens and how to choose?

Wire rod is required in many areas of industry and construction. The demand is explained by the properties of the product. It is often used as a finished product, and also serves as a raw material for making thinner wire. You should know what types of wire rod are, and what to look for when choosing.

What it is?

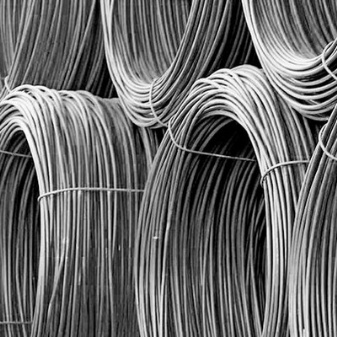

Wire rod is a type of rolled metal. This is a wire that has a circular cross-section. It is sold in coils and can be made from different grades of carbon steel, namely: St0, St1, St2, St3.

And also, according to GOSTs, it can be based on a non-ferrous metal or its alloy, provided that the TU is observed. Depending on the material of manufacture, this product may have a different specific weight and diameter.

Steel wire is sold with a diameter of 5 to 9 mm, and a non-ferrous metal product can have a value of 1–16 mm. And also a technology is possible when wire rod is made with a large diameter, but this happens exclusively on order and in limited quantities.

The production of this type of rolled metal is carried out on special equipment by rolling or drawing. Cubic blanks go to workshops, where they are divided into smaller ones. The next step in the manufacture of wire rod is to pass through several successively installed rows of shafts. As a result, all-round crimping of the material takes place, and the wire takes on the required shape. After that, the wire is directed to the winding machine, where it is wrapped in rings.

In some cases, the wire rod is galvanized, which adds certain properties to the product. Coated metals are corrosion resistant, shiny and do not need painting. The consumer can buy wire rod in a coil, the weight of which is more than 160 kg. In it, the wire looks like a continuous section. According to the requirements, the product must have good weldability, and also be free from cracks, dirt, captivity.

The wire must be flexible and also withstand bends up to 180 °. Storage of products is carried out in coils in a specially equipped warehouse. Often, this type of material is made round in cross section, but for decorative and technical purposes it can be made oval, semicircular, square, hexagonal, rectangular, or another type of cross section.

Scope of application

Hot-rolled wire has a circular cross-section, so it is often used in construction to reinforce reinforced concrete structures. And also the wire rod is used for artistic forging.

By subjecting the product to various types of mechanical stress, you can make an openwork beautiful structure, which in the future will decorate the gate, the facade of the building or become part of the decor in the interior.

Wire rod is considered an excellent basis for the preparation of a welding cable, electrodes, rope, telegraph wire. And also wire of a smaller diameter is produced from it, without which it is difficult to imagine the supply of electricity and the construction process. Copper rolled products are quite common in telecommunications, automotive and electrical engineering. Steel wire rod is used in the manufacture of nails, mesh, screws and fasteners. Aluminum products are indispensable for creating electrodes for welding and steel deoxidation.

Galvanized wire is used at construction sites, in industrial plants.

It comes in different types:

- for welding;

- reinforcement;

- spring;

- cable car;

- cable;

- knitting.

Comparison with fittings

Due to its unique properties, wire rod has high performance characteristics, for this reason it is used in the following areas:

- for grounding the loop;

- for reinforcing concrete structures;

- manufacture of products of their reinforced concrete and metal;

- in the production of nets, cables, fasteners;

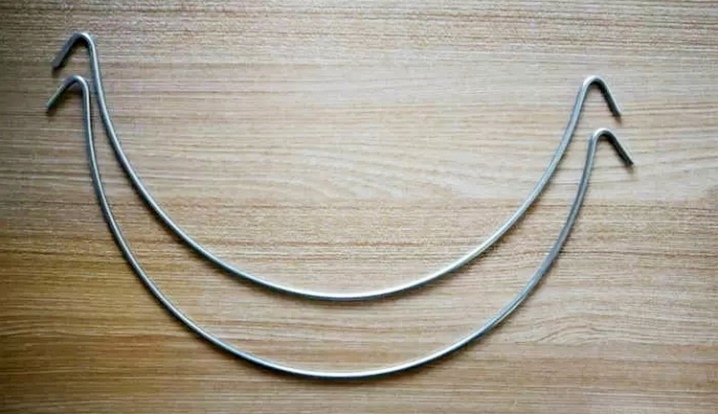

- for the manufacture of some household appliances, for example, bucket handles, clothes hangers, box fasteners.

The appearance of wire rod and reinforcement of A1 class is practically identical, so it is difficult for the consumer to find differences. Both types of products are produced at metallurgical enterprises and sold in bays. Despite the fact that wire rod and reinforcement A1 have a similar externally description, they differ in mechanical properties, which are determined by the characteristics of rolled metal:

- technology and manufacturing standard;

- steel grade;

- the use or absence of heat treatment.

General purpose wire rod is manufactured in accordance with GOST 30136-95 or other specifications. Heat treatment is possible during manufacture.

In contrast to wire rod, rebar is characterized by a diameter of 6 to 40 mm, which is significantly larger than that of the described product.

The production of class A1 rolled metal is regulated by GOST 5781-82, and its use is popular in reinforcing structures and elements made of reinforced concrete.

Species overview

There are several types of metal wire rod in coils.

- Copper. Rolled metal of this type is produced by continuous casting of molten copper, after which it is subjected to rolling on the shafts of special machines in accordance with GOST 546-200. This product is of 3 classes: A, B, C. Often, copper wire is used for the manufacture of electrical cables and wires that can withstand high loads. Copper wire rod is designated as MM. Copper wire obtained by continuous casting and rolling of refined waste - Kmor, oxygen-free copper wire - KMB.

- Aluminum wire rod looks like a rod that has a circular cross-section. The product is characterized by a diameter of 1–16 mm. The production of rolled metal can take place in several ways: from molten metal or through blank rollers. The production of aluminum wire is carried out in accordance with GOST 13843-78. According to experts, making wire rod from aluminum will cost at least 3 times cheaper than from copper. This type of wire has found its application in power supply, for example, in the production of cables, power wire shields.

- Stainless wire rod most often sold with a diameter of 8 mm. It is necessary for earthing systems as well as for lightning protection.

- Steel wire rod is divided into 2 classes in terms of strength: C - normal and B - increased. This characteristic is determined by the materials used, as well as the cooling option. GOST 380 indicates that the coil of the product should be twisted from solid cores. And also, along the entire length of the wire, there should be no deviations in the diameter. The hot-rolled product is widely used for reinforcing concrete structures. With the help of GK, monolithic columns, girders, belts, foundations are formed. Often, steel wire is used during the laying of load-bearing walls or a brick, cinder block, foam block wall.

A common type of wire rod can be called galvanized. It has a rounded cross-section, the diameter indicator ranges from 5 to 10 mm. This type of product is made from carbon steels by using a hot rolling drawing mechanism. A feature of this type of rolled metal is zinc coating.

Such wire rod is appreciated by consumers due to the following points:

- anti-corrosion resistance;

- strength and reliability;

- resistance to dynamic, static, linear load;

- it lends itself easily to various types of processing, namely: cutting, bending, stamping.

In addition, galvanized metal products have a more aesthetic appearance, which is not typical for other options.

Manufacturers

Wire rod manufacturers strictly monitor the quality of their products, so it is produced in accordance with GOSTs. Currently, a large number of brands of this rolled metal are known.

There are many popular wire rod manufacturers:

- Liepajas Metalurgs - Latvia;

- TECRUBE - Azerbaijan;

- "Absolute" - Russia;

- Alkor Trading Company - Russia;

- Amurstal - Russia;

- Areal - Russia;

- "Balkom" - Russia;

- Belarusian Ministry of Health;

- VISMA - Belarus;

- Danko - Ukraine;

- Dnepropetrovsk MZ;

- Dneprospetsstal - Ukraine.

This list of companies that are engaged in the production and sale of wire rod made of copper, steel, aluminum cannot be called complete, there are much more of them in Russia and the CIS countries.

Selection Tips

Typically, factories and large industrial enterprises buy wire rod from non-ferrous metals. For construction or installation, a steel type of wire is purchased. When buying, you need to know that the product should be sold in skeins. Hanks, as a rule, include 1 or 2 strands. And also it is worth knowing that with a two-core skein, 2 labels should be present on the product.

The correct marking of steel wire can be called the following: "Wire rod V-5.0 mm St3kp UO1 GOST 30136-94".

From these designations, it can be concluded that the product has normal strength and a diameter of 5 mm. The product was produced using accelerated cooling. This product fully complies with GOST.

In addition to studying information from the manufacturer, you need to conduct a visual inspection of the cores. The product should be free of scale, cracks, burrs. A defective product is one that has voids, bubbles and a lack of carbon. And also do not ignore the general color of the wire rod. If the color is uniform, then you can be sure that the wire will be strong and flexible along its entire length.

For various works in which wire rod can be used, specific requirements are imposed on its properties. When buying a wire, it is imperative to evaluate the length and size of its cross-section, the cost of wire rod per 1000 kg directly depends on these characteristics. And also the cost of the goods is influenced by the material from which it is made.

Copper wire is considered the most expensive, aluminum is 2 times cheaper, steel is the cheapest, the cost of which does not exceed 30 rubles. for 1000 g. On request, the consumer will be able to buy a coil of wire rod, in which from 160 to 500 kg. And also in small retail trade you can find skeins with less weight.

The transportation and storage of wire rod coils takes place lying down.

For more information on wire rod production, see the video below.

The comment was sent successfully.