The choice of wire for welding aluminum

Aluminum welding is a complex technological process. Metal is difficult to weld, which is why it is necessary to choose consumables for work with special care. From the material of this article you will learn how to choose a wire for welding aluminum, what it is, what features it has.

Peculiarities

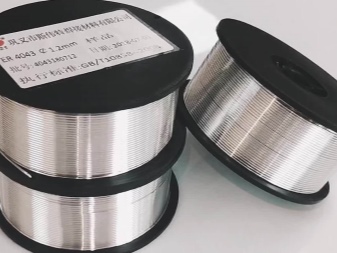

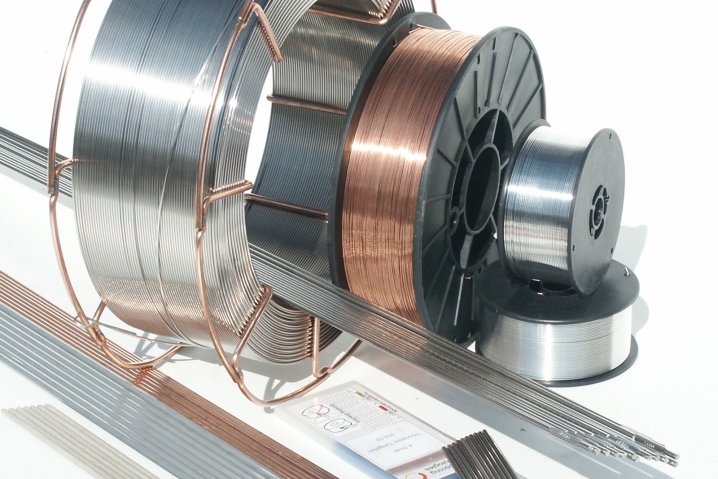

Aluminum welding wire - small section aluminum filler wire, supplied in the form of rods or in spools. Its weight is measured in kilograms, it is used for welding aluminum, which only experienced welders can do. This consumable is used for welding on semi-automatic machines.

There is a refractory oxide film on the surface of aluminum, which interferes with high-quality welding. High alloyed welding wire needs additional protection.

Because of this, argon arc welding is used to reduce the negative effects associated with environmental influences due to insulation.

During welding, you have to monitor the filler material. During the manipulations of the master, the consumable needs protection. Therefore, it is necessary to use a specialized material that is automatically fed into the welding zone at the same speed. Moreover, the speed of its supply is higher than, for example, copper.

Aluminum is a soft metal with a low melting point. The filler material for its welding transfers its characteristics to the weld seam. The stronger it is, the stronger the seam itself. In this case, the welded material can be different, so that it can be selected for a specific alloy with aluminum (products from it usually have different additives that increase its strength).

Typically, such a wire does not change its properties when the temperature changes. It does not rust, it has a wide range of nomenclature... This makes it possible to select the filler material of the required diameter as accurately as possible. At the same time, the wire is suitable for both manual and automatic welding.

However, it has several disadvantages. For example, an oxide film is also formed on it, which is why it needs preliminary processing.

Failure to do this will affect the quality of the welds. It is also bad that a large assortment complicates the choice, when it is not known exactly what material will have to be welded.

The filler wire derives its main properties from aluminum. Due to the high speed of its melting, it is important to monitor the accuracy of adjusting the speed of wire feed to the welding working area. When working with it, there is no need for high temperatures. Moreover, during operation, the wire does not change color, which can complicate heating control. It does not reduce the electrical conductivity of aluminum.

Views

The welding wire has a diameter ranging from 0.8 to 12.5 mm. In addition to coils, it is sold in the form of coils and bundles. It is often packed in sealed polyethylene bags along with silica gel. The diameter of the drawn variety does not exceed 4 mm. Pressed varies from 4.5 to 12.5 mm.

The chemical properties of a wire for welding aluminum steels with a semiautomatic device without gas are determined by its composition. Based on this, several types of consumable welding consumables can be distinguished. In this case, the marking indicates the content of aluminum or other additives in the wire:

- for work with pure aluminum (metal with a minimum amount of additives), filler wire of the grade SV A 99which consists of almost pure aluminum;

- when it is planned to work with aluminum with a small proportion of additives, use a wire of the brand SV A 85T, which, in addition to 85% aluminum, includes 1% titanium;

- in work with aluminum-magnesium alloy, welding wire of the brand is used SV AMg3which contains 3% magnesium;

- when it is planned to work with a metal in which magnesium predominates, a specially designed wire with markings is used in the work SV AMg 63;

- for metal containing silicon, a welding wire has been developed SV AK 5consisting of aluminum and 5% silicon;

- SV AK 10 differs from the previous type of consumable wire raw material in a large percentage of silicon additives;

- variety SV 1201 designed to work with aluminum alloy containing copper.

Filler wire for aluminum welding is produced with an orientation to 2 main standards.

GOST 14838-78 indicates that this product is designed for cold heading from aluminum and its alloys, in which it dominates. GOST 7871-75 - standard for wire used exclusively for welding aluminum and its alloys.

In addition to aluminum / silicon combinations, aluminum / magnesium, manganese-doped aluminum wires are also commercially available. In most cases, universal-purpose consumable raw materials are purchased for work. While versatility is considered relative, this wire provides high quality weld seams. It does not magnetise, it is a unique electrode of a special type.

How to choose?

The choice of aluminum wire for welding must be correct. The quality and reliability of the formed welds depend on this, and in addition, the stability of their mechanical characteristics. To purchase a really high-quality consumable, you need to consider the following parameters:

- tensile strength of the seam;

- ductility of the welded joint;

- rust resistance;

- resistance to cracking.

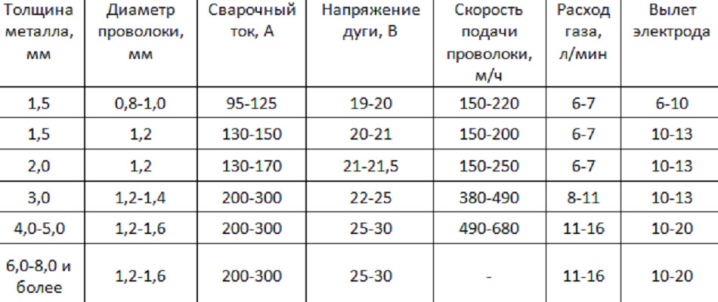

Select a welding wire taking into account the object to be welded. The diameter of the consumable should be slightly less than the thickness of the metal... For example, for sheet aluminum with a thickness of 2 mm, a rod with a diameter of 2-3 mm is suitable.

In addition, you need to know the composition of the object for which the consumable is being purchased. Ideally, its composition should be identical to that of the metal.

A component such as silicon gives the wire strength. In other modifications, it may contain nickel and chromium. These consumable raw materials are used not only in mechanical engineering, food, oil and light industries, but also in shipbuilding. High quality aluminum welding wire is an indispensable element for arc welding.

If you do not know exactly what is included in the available material for welding, it is better to buy a universal filler wire for working with aluminum with the SV 08GA marking. In this case, it is necessary to take into account the volume of consumable raw materials. If a small amount of work is planned, it makes no sense to buy large coils of wire.

If a long and similar work is planned, you cannot do without a large stock of material. In this case, it is more profitable to buy coils that differ in the maximum length of the wire consumable. In order not to be mistaken in the choice, you should pay attention to the melting temperature of the metal and the wire itself. You will have to work quickly so as not to burn through the metal. Therefore, it is necessary that it be identical.

It differs mainly due to the presence of impurities in the composition. The more the composition of the wire and metal differs, the worse the quality of the weld.

Auxiliary additives in the composition of alloys can cause the metal to overheat, and the wire does not reach the required state for welding.

To be sure, you can pay attention to the brand. Ideally, the grade of wire and metal to be welded should be identical. If it does not match, it can affect the quality of the welds.

You can buy quality wire material from trusted manufacturers. These brands include ESAB, Aisi, Redbo and Iskra.

When choosing an overlooked option, one must not forget the key rule. The use of the material must be timely... After opening the package, the storage time must be reduced to a minimum value. The longer the wire is stored, the faster it will deteriorate. The utmost care should be taken when storing material in high humidity conditions.

When buying, it is worth considering that small coils with wound wire for welding aluminum are not suitable for all machines. If in the selection of this or that option there are doubts, you can consult with a sales assistant.

Better yet, go to the manufacturer's website and ask him what kind of wire is suitable for working with a specific metal.

Nuances of use

Using a consumable for aluminum welding is not so easy. The filler material is prone to warping and has a high coefficient of linear expansion. The metal is not elastic, which can complicate welding. In view of this it is necessary to ensure the rigidity of fixation of the welded object, for which different weights can be used.

Directly before the welding process itself, a preliminary preparation of the metal is carried out. The surface of the object itself and the wire is cleaned of the film by means of a chemical solvent. This will minimize the likelihood of crystalline cracking. Pre-heating the workpieces to a temperature of 110 degrees will help to simplify the work and avoid the appearance of cracks.

See below for how to select a filler rod.

The comment was sent successfully.