How to bring the pipe through the corrugated board and how to seal it up?

The roofs of houses, which are made of corrugated board, have long earned prestige among home owners due to their small mass, attractive appearance, and also their durability. Decking is a thin, but rather strong metal that is resistant to corrosion. For heating houses with such a roof, wood stoves or gas boilers are usually installed, as well as solid fuel stoves. In this article, we will try to figure out how to cut a hole in the profiled sheet in order to ensure the passage of the sandwich pipe with our own hands, bring it out and seal everything.

Place for withdrawal

The selection of a good place for making a hole in the roof from corrugated board under the chimney pipe is an extremely important aspect of the whole process. Of course, a lot will depend on where the oven is located. It is recommended, of course, to place the chimney as vertically as possible, but there are a number of other nuances that need to be taken into account.

- It would be better to place the chimney hole at the highest point of the roof, that is, as close to the ridge as possible. The distance between the ridge and the chimney should be in the range of 500-800 mm.

- It is optimal that the hole in the roof of the type in question does not fall on the parts of the rafter mechanism. To bypass it, you can use bends, as well as corner elements of the chimney. Their use allows you to set turns at 45-90 degrees.

- The length of the parts of the chimney system is calculated so that the joints are located above or below the transition points of the floors and the roof itself... Otherwise, it will be very difficult to make a strong connection.

- To ensure high-quality traction, the height of the chimney mechanism should be somewhere 100-150 cm above the roof ridge.... If the output is too high, then as the smoke passes through it, it will cool down, due to which condensation will form.

To be sure that the chimney exit point is determined correctly, you can apply a marker or pencil on the roof with a mark and check the temperature in the evening.

It is required to install the pipe in the "cold area", that is, it must be in the shade all day long.

How to display correctly?

Before starting to withdraw the pipe through the roof, it is necessary to carry out a number of preparatory works.

- Define dimensions pipes.

- On corrugated board circle holeswhere the iron pipe will be installed.

- Now, according to the applied marks, cut the sheet. It is best to do this with a grinder with a thin circle for working with metal. You should act as carefully as possible so as not to make burrs.

- When cutting a hole, retreat a couple of centimeters from the applied contour.

- Cuts made at the corners of the perimeter, will make it possible to bend the edges of the sheet to the roofing plane.

- Between the chimney and the rafter, you need put a box that has about a 15 centimeter gap... It is usually located in the attic.

- Hole with the same size must be done in the ceiling.

- The layer of insulation and waterproofing should be removed. It is not required to make holes in them, but it is enough just to make a slot according to the envelope principle and bend the edges, which are fixed with self-tapping screws or staples.As a result of the manipulations done, a through-type hole should be obtained.

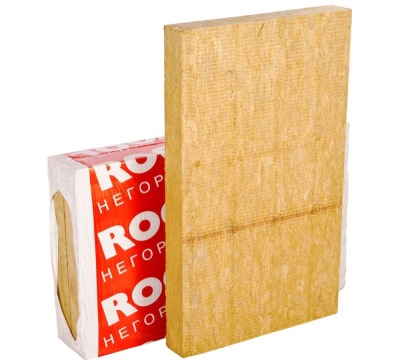

In addition, thermal insulation and insulation of the corrugated board should be provided before the pipe is removed. This moment will protect the building from the possibility of fire due to overheating. The best way to do this is to use stone wool. It has excellent hygroscopic characteristics and will be a good insulation.

When the iron pipe has been insulated, you can install it in a box. The tape with an adhesive base will provide protection of the edges of the vapor and waterproofing tapes from condensation.

Note that the woodwork and piping are assumed to have a 5cm gap.

Also, it will not be superfluous to use steel clamps to fix the pipeline at the joints with the rafter system and the crate made of profiled sheet. They will not allow the structure to skew or collapse. It will not be superfluous to use asbestos here. If the pipeline is made of bricks, then the gaps can be sealed with bricks placed on the clay mortar.

Finishing features

Now it is required to finish the space around the pipe from the outside. It is important to close the gaps correctly between the corrugated board so that various kinds of precipitation do not get there. To do this, sheathe the space using galvanized metal or stainless steel.

This structure is a flat sheet base to which a cone with a cut off top is attached. It is put on the chimney, after which it is sealed, and the base is fixed on the roof covering. This allows you to get a high-quality and reliable unit that will be reliably protected for decades.

It should be added that there are alternative solutions for finishing this area using a steel apron or aprons that are made of rubber. Also, lately a new word has been used in this matter - self-adhesive foil tape made of modified bitumen... This material is equipped with a self-adhesive bitumen layer. In turn, it has a silicone film that must be removed before gluing. And the top layer of the foil type perfectly protects the tape from heating and the harmful effects of ultraviolet radiation.

How and how to seal?

Now it is required to close the gap between the pipe and the corrugated roof. This can be achieved by sealing the area. Let's try to figure out how to do this in different cases. If there is an abutment to a brick pipe, then the whole process is divided into 2 stages:

- installation of an apron;

- ensuring its tight fit to the roof.

The roof is prepared first... For this, the waterproofing should be placed on the pipe and secured. This is often done in a bathhouse. There should be no slots here so that condensation does not get inside.

Sheathing boards must be installed above and below the pipe. This prevents the apron from hanging. Now everything needs to be cleaned and degreased.

After that either an apron is mounted with the subsequent sealing of the joints of parts of the additional type, or folding is carried out... In the first version, the installation begins with the fitting of the lower adjoining strip to the pipe. Chimney corners are marked here, after which it is necessary to retreat from them 20-30 millimeters and cut off a piece of the upper shoulder of the part of the extension. Where the corner is bent, an incision is made and the bar is bent to grip. Now along the length of the roof self-adhesive butyl-based tape is applied, and a sealant is placed on topso that dirt does not accumulate under the apron and sealing is carried out.

The joint located between the pipe and the roof is closed with an abutment bar. Since the work takes place with corrugated board, the fixing is carried out using roof-type self-tapping screws with a gasket made of EPDM rubber. Self-tapping screws are screwed perpendicular to the sheet on top of all the waves. From the sides, the strips are attached in about the same way.They are cut to fit the dimensions of the pipe, bent, but mounted only on a sealant and butyl-based tape. And the sealant is applied only to the bottom of the apron so that it covers only the line of the strip joint. The step between the self-tapping screws when attaching these strips cannot be more than 150 millimeters.

The width of the lower part of a solid element should be at least 450 millimeters with a 15-degree roof slope. On roofs with a large slope, the upper apron should be wider. It is required to coat the entire plank joint with the roof with sealant, including the bottom and sides.

Where the abutment support sheet is located under the top sheet of the corrugated board, a plank, which is fastened with self-tapping screws with flat-type hats. So the fasteners will not interfere with the laying of the roof covering. Where the part will be open, the bar can be attached using ordinary self-tapping screws.

A sheet of corrugated board can be laid on the upper abutment bar, which should be brought under the ridge.

Before laying on the flat surface of the lower shoulder, it is required to stick a self-adhesive tape, and then a sealant is glued to it and a sealing compound is applied. The roofing material will be attached here in the same way as in other places.

How to close the pipe?

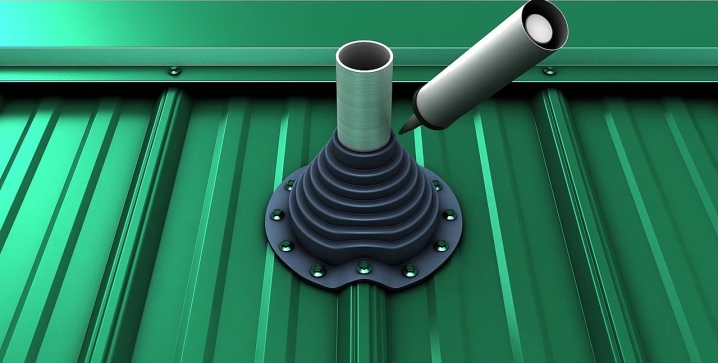

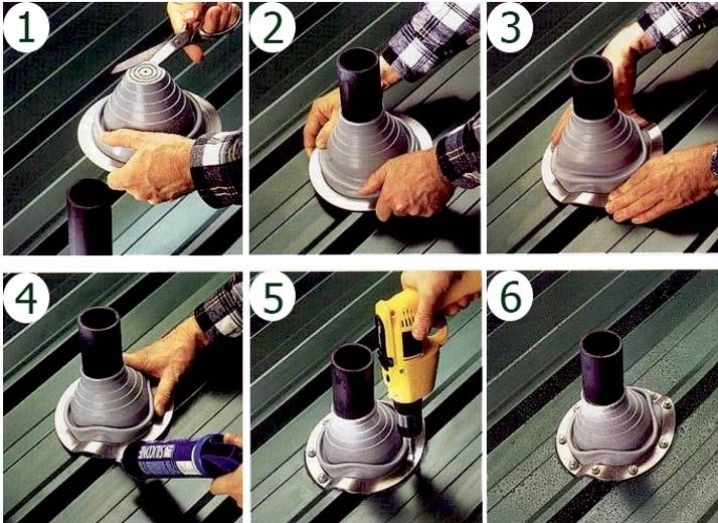

If you need to close a round-type pipe on a roof made of corrugated board, you can use an adapter called "master-flash". Its installation on a roof made of corrugated board will be carried out taking into account the following features.

- If the roof is high, then the adapter must be installed with a diamond.

- If possible, then fastening of the adapter to the corrugated board should be carried out both to the bottom and to the top of the wave.

- The master flush must be sealed twice... First when gluing, and then at the folds. The reason is that it is simply impossible to give the base a shape that will accurately copy the corrugation of the sheet roof.

With the use of an elastic-type adapter, it is possible to seal only heat-insulated oven-type pipes and ventilation. But for non-insulated alternatives, it would be better to use a sealant and steel clamps. The joints of the clamp and pipes with steel sheets are coated with a sealed compound.

Recommendations

If we talk about the recommendations for the withdrawal of the pipe through the corrugated board, then the first point that should be said is that there is no need to make attempts to violate the technology. Saving any material will be extremely doubtful, but problems with cracks and a roof can be for sure.

It is not necessary to make the pipe too large to be taken out of the house. Otherwise, the smoke will cool down quickly and condensation will form in the pipe.

The joint must be repaired. Otherwise, the roof of the house will not last even half of the expected period. In addition, it will be very uncomfortable in the attic of the house in the winter season.

Below you will find a useful video on sealing the joint between pipes and corrugated board.

An excellent option, just what I need. Thanks to the master.

The comment was sent successfully.