Types of skates for corrugated board and their installation

Among all the works performed during the installation of the roof, a special place is occupied by the installation of ridge for corrugated board. Despite the apparent simplicity, it requires taking into account many nuances, determined by the type and size of the planks used. Seals are also noteworthy - without their use, it is impossible to achieve an optimal level of insulation.

Description and purpose

First of all, it is worth noting that two completely different elements of the roof structure can be called skates. The first is a joint formed by a pair of adjacent slopes and located at the highest point of the roof. The second element, to which the presented material is devoted, is additional and looks like a bar for overlapping the above connection.

Usually, ridge linings are made from the same material as the roof covering. To achieve the best possible appearance, their shade should match the tone of the profiled sheet, ideally blending in with it.

As for the procedure for installing the ridge, it is necessary for all roofing structures, except for flat ones.

Due to the fact that the considered additional element closes the gap between the slopes, it performs 3 main functions.

- Protective. The use of roof ridge minimizes corrosion processes, rafter wear and damage to the battens. The absence of overhead strips reduces the service life of the roof and reduces its thermal insulation qualities.

- Ventilation. Upon completion of the installation, a small space is formed between the ridge and the roof, allowing air circulation. In addition, the presence of full ventilation prevents the formation of condensation - the main enemy of most heaters.

- Decorative. Cover strips cover the gap between the slopes for the best visual effect. If the shade of the ridge is chosen correctly, it looks like an organic continuation of the laid roof.

The combination of the above qualities guarantees trouble-free operation of the roof for 3-4 decades.

Types and sizes

As mentioned above, roof skates are most often made from the same material as the corrugated board. This is galvanized steel, often coated with a polymer layer for better wear resistance. In most cases, ridge linings are produced at the factory, but some craftsmen prefer to make them with their own hands - using a bending machine.

Practice shows that the first option is not much more expensive than the second, and therefore it is not very popular. For most planks, the average section length is 2-3 m, and in the case of a triangular version, this value can reach 6 m. Special attention should be paid to the types of skates, determined by the shape of the product.

There are 3 traditional options - corner, U-shaped and rounded.

Corner

The second name is triangular. They are lining in the form of a reverse groove, the opening angle of which slightly exceeds the straight line. To make the corner skates more durable, their edges are rolled. Such products do not differ in originality, and their main advantage is a reasonable price.

The dimensions of the shelves of the corner plates range from 140-145 mm to 190-200 mm. The first option is suitable for standard roofs, while the second is for longest slopes.As for the edge, its width varies in the range of 10-15 mm (this value is relevant for any type of skate).

U-shaped

One of the most original solutions from a design point of view. These skates, often referred to as rectangular skates, have a “P” top that acts as a ventilated pocket. This feature provides full air circulation, which is essential for any room. Such pads are more expensive than corner pads, which is explained by the complexity of their manufacture and a large amount of consumable material. The standard width of rectangular ridge skates is 115-120 mm, the size of the stiffener is in the range of 30-40 mm.

Rounded

These onlays, also called semi-circular, have one characteristic feature. They are installed in situations where a corrugated corrugated sheet is used. Such elements not only resist the formation of condensation, but also have an excellent appearance.

Their only drawback is their high cost.

The average rounding diameter of the considered linings is 210 mm, the size of the side shelves is 85 mm.

How to improve protection?

Although the skates cover the gap at the junction of the two ramps, they cannot guarantee a complete seal. To solve this problem, a sealant is used - an element of the roof that is invisible from the outside, which increases the efficiency of using overhead strips. In particular, he:

- ensures the tightness of all joints, filling any gaps;

- acts as a barrier, preventing debris, dust and insects from entering the space under the roof;

- protects from all types of precipitation, including those accompanied by a strong crosswind.

At the same time, the structure of the seal allows it to freely pass air, so that its use does not interfere with ventilation.

There are 3 main types of materials considered.

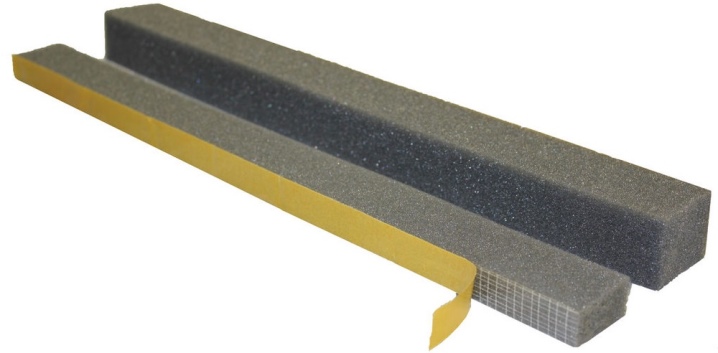

- Universal. It is made in the form of a tape made of foamed polyurethane foam. A characteristic feature is open porosity. Often, one of the sides of such products is made sticky, which has a positive effect on the convenience of work. The air permeability of the material is sufficient, but not optimal.

- Profile. Such seals are characterized by greater rigidity and closed pores. Unlike the previous variety, they are made from polyethylene foam. They are able to repeat the profile of the sheet, due to which they completely close the gaps between the overhead strips and the roof. In order to avoid a decrease in the level of air circulation, special holes are provided in such a seal. The latter can be left closed - subject to the availability of pitched or ridge aerators.

- Self-expanding. It is made of polyurethane foam impregnated with acrylic and equipped with a self-adhesive strip. After installation, such material can be increased 5 times, effectively filling any gaps. Requires the installation of aerators.

The first option can boast of the lowest cost, while the third guarantees the maximum degree of compaction.

Preparation

Before proceeding with the installation of ridge linings with your own hands, you should pay attention to the following points.

- Determination of the type and number of assembled products. When calculating the latter, it must be borne in mind that the installation of the skates is overlapped. Special attention should be paid to the dimensions of the overhead strips - making mistakes can affect the appearance and functionality of the finished structure.

- Installation of the lathing. It should consist of a pair of boards placed next to each other, be solid and located under the upper edges of the roof. This condition is explained by the fact that the fastening of the skates is carried out precisely in the crate.

- Checking the distance between opposite profiled sheets. The optimal value is from 45 to 60 mm. A smaller distance between the upper edges makes it difficult for steam to escape from under the roof, and a large distance prevents the correct installation of the linings.

- Inspection of the junction line of two slopes. It is desirable that it be perfectly flat, and the maximum permissible deviation is 2% of the width of the shelf.

In a situation where the last condition is not met, there is a risk of roof leakage. To avoid this problem, you should choose a skate with a wider shelf.

There is an alternative solution - re-installation of roofing materials, however, in comparison with the previous method, it is less rational.

Mounting

It is advisable to start work on installing skates for corrugated board from the leeward side of the roof, in accordance with the following algorithm.

- Installation of the seal. If the selected material is equipped with a self-adhesive strip, the work is greatly simplified. In other cases, the fixation of the insulation is carried out using improvised means. The material can be attached both to the back of the skates and to the profiled sheets.

- Installation of overhead strips. For most types of products, it is performed with an overlap of 15-20 cm. The exception is rounded roof ridge, which has a stamping line. If you need to cut a bar, it is advisable to use metal scissors rather than an angle grinder. This recommendation is especially relevant for polymer-coated patches.

- Final fixation. After making sure that the ridge for the corrugated board is located exactly, it remains to fasten it using the roofing screws. They should be driven into the crate, passing through the metal layer and maintaining a distance of 25 cm between adjacent points. It is equally important that the self-tapping screws are at a distance of 3-5 cm from the bottom edge of the cover strip.

To simplify the installation procedure, experts advise you to first fasten the skates at the edges, and then screw in all the other screws. The most suitable tool for this task is a screwdriver. As for the nails, it is permissible to use them for installation, but undesirable: in the event of a hurricane wind, such fasteners may not cope with the load and break out.

Summing up, it remains to state that correctly installed skates for corrugated board protect the roof from many negative factors, guaranteeing its reliability and durability. The validity of this thesis is regularly confirmed by practice, and everyone can be convinced of this from their own experience.

The comment was sent successfully.