Sealer for corrugated board

Today, profiled sheet roofs are gaining more and more popularity due to their affordable cost. Moreover, this material can be seen both on simple structures and buildings, and on rich cottages. However, it must be remembered that the roof is a complex element in architecture, and many points must be taken into account when designing it. For example, you should know how to correctly select and use a corrugated board seal.

What is it and what is it for?

The corrugated board compactor is very important when assembling complex roofs. They have an element such as a ridge (ridge connection). It is understood as a line that is located at the junction of the roof slopes. Profiled sheets are made in a trapezoidal shape and need to be compacted in such critical places.

During installation, you should use a seal, since the ridge must be carefully secured. Otherwise, snow, rain or gusts of wind can penetrate through it into the roof.

It should also be understood that profiled sheets have irregularities that form cracks and gaps, which can be removed by compaction. However, there should be small ventilation holes in the ridge connection. At the same time, moisture should not penetrate through them.

You can qualitatively compact the corrugated board using the optimal type of material. This is necessary so that the roof arrangement is correct and there are no leaks. Tapes made of porous materials characterized by increased resistance to moisture are used as sealing elements.

It is necessary to seal the profiled sheets on all sides of the ridge under the profiled sheet. Usually, a material is laid under the element, which is close in its properties to that with which the roof is covered. The result is a snug fit and moisture resistance.

Skate compactors show good resistance to snow and rain even with a long service life. However, for this it is important to avoid creasing and deformation during installation. It should be noted that the seal is also breathable. This allows fresh air to enter under the roof. A variety of sealing materials in shape makes it possible to choose the right option for any profiled sheet.

Species overview

For a profiled sheet, depending on the type of its profile, a different seal is required. It is worth clarifying that any sealing materials for the ridge are moisture resistant, fireproof and noise suppressing. Each type of seal has its own characteristics.

Universal

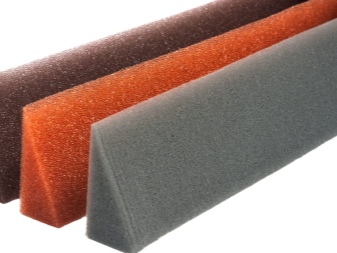

The universal option is used most often due to affordable prices and ease of use. Such a seal is produced from a synthetic substance based on polyurethane.

In shape, it can resemble a triangle or rectangle. There is adhesive tape on one side.

With the right size, the universal look is able to create low air resistance, which will be an excellent solution for insulated roofs.

Profiled

The profile version of the insulation is good only if the profile is 5 centimeters or more. Polyurethane foam is also used to create a seal, but only modified. The strength of this material is higher. The profiled appearance is distinguished by precise shapes. It also has special openings that allow air to pass through.

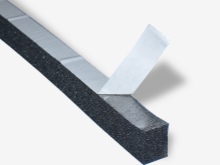

Self-expanding

Self-expanding sealing strips are not so long ago and are very expensive.Their distinctive property is that in the process of fastening under the ridge, their dimensions increase. This way, all gaps remain well filled. Self-adhesive tape applied to one of the sides makes the installation of such a seal extremely simple. This insulation is made of compressed polyurethane foam impregnated with a solution with polyacrylates.

Selection Tips

Roof sealing tape must be correctly selected, and this is not always easy to do. First of all, it is important to understand what kind of work (for a pipe, a ridge, and so on) one or another type of seal is suitable.

The sealing of the corrugated board must ensure sealing and waterproofing.

It is very important that the material from which the seal is made does not absorb moisture. For example, foam rubber does not differ in such properties.

Another parameter that should be considered when choosing is thermal insulation. The optimum heat transfer rate through the seal (thermal conductivity) is from 0.02 W / (m · ° C).

Profiled sheets are a rather loud material for roofing, so it is advisable to opt for a seal with good sound insulation properties. It is also desirable that the product tolerates exposure to various chemicals well.

The sealing gasket must necessarily have such a property as fire safety. Decking is a metal material that gets very hot when exposed to the sun. Therefore, it is very important that the ridge seal can withstand a wide range of temperatures.

It is advisable to choose the tape for sealing immediately together with the roofing, so that their shapes completely coincide. It is also important that the size of the sealing material matches the wave height on the profiled sheet. The maximum deviation allowed is 1 centimeter. Not every ridge has stiffening ribs, so if you use a too thick sealant, the appearance of the roof may deteriorate.

If possible, it is better to give preference to a triangular shape rather than a rectangular one. This is due to the fact that the tops of the triangle have thin sections, due to which natural air circulation is ensured.

If there is no ventilation, the wood on the roof can be damaged by rot.

When choosing, special attention should be paid to the expiration date of the seal. It will also be useful to find out how and in what conditions the products were stored. Indoor spaces are optimal for this. If the sealing strips are exposed to direct sunlight, their service life will be greatly reduced. It also worsens the condition of the adhesive strip.

It is worth noting that self-expanding tapes are very beneficial. Indeed, in addition to the ease of installation, work with them can be done even faster if you use a construction hairdryer.

Installation instructions

Work on installing the seal should be started with preparation. First, you need to clean the area where the fastening will be made from dust and various debris. It is important to install the sealing strips (expanding or with a self-adhesive strip) evenly so that there is no twisting or deformation. Before installation, check the joint lines for evenness.

It is important to remember that you should not completely shut off the flow. Damp air outlets must be provided.

When arranging a roof like a tent, you need to especially worry about tightness and protection from moisture.

The easiest way is to work with a universal self-adhesive seal option. It must be laid on the right side and just pressed down with a professional sheet. This option is especially suitable for insufficiently experienced craftsmen.

When installing, it is important not to forget about safety precautions, which directly affect life and health. So, it is obligatory to have and use a safety belt.

In general, the installation of the seal consists of several stages.

- Caps are placed on the end skates, which are included in the kit. It is better to do this procedure on the ground. Usually they are mounted on a pair of extreme elements and fixed with self-tapping screws. If a gap is visible after installation, then it should be sealed with silicone sealant.

- The protective coating is removed from the seal, and it is attached to the profiled sheet. If there is no self-adhesive strip, then a sealant must be applied. To speed up the work, you can use the carpenter's belt, on which it is convenient to attach work items.

- After that, the first skate is installed and screwed on. In this case, the sealing tape should only be pressed from top to bottom, evenly and without stretching.

- These operations are repeated until all the ridge seals are installed.

If necessary, connection or extension is done end-to-end. In the cold, you can also lay the sealant, but before that it must be warm for some time. The sealing layer should only be applied on a dry and preferably degreased surface.

The comment was sent successfully.