The thickness of the profile for the fence

Temporary or permanent fencing of private plots, as well as industrial areas, is often made of corrugated board. Depending on the purpose of the fence being erected, it is necessary to accurately select the parameters of this material. After all, if the corrugated board is too thin, then such a barrier will not last long. Therefore, it is worth considering the entire set of characteristics of such a material and barrage structures erected from it.

What does it affect?

There are different types of corrugated board. They differ in the materials used for production and the spray applied, as well as the thickness of the sheet itself, which gives a certain flexibility. Differing characteristics provide different parameters of the fencing being erected. Therefore, it is initially necessary to understand the features of this material.

The simplest and most short-lived, from the point of view of use, is the so-called rough corrugated board. It breaks down quickly enough, as it becomes covered with corrosion.

This is due to the fact that ordinary steel is used for the production of such sheets, on which no coatings or sprays are applied. Due to the fact that such sheets quickly deteriorate, they are used less and less.

It is more rational to use profiled sheets with galvanized or polymer layer. This prevents the corrosion process and allows the use of corrugated sheets for 20 years without changing their appearance. It should be borne in mind that the thickness of the layer directly affects the quality of such a material. And if with galvanizing everything is more or less clear, since galvanized steel is a fairly familiar material that has long been used for the construction of fences and for other purposes, then it is worth understanding in more detail with the polymer coating.

These are the types that are present on the construction market.

- Polyester coated profiled sheets can be either glossy or matte. This is a fairly simple option, but at the same time it provides a high level of resistance to corrosion. True, the polymer layer cannot withstand mechanical damage.

- The application of plastisol to a steel sheet 200 micrometers thick forms a relief embossing. A kind of notch in the form of strokes is formed on the surface. Profiled sheeting with a plastisol layer can be used even in the most unfavorable conditions.

- There is also a kind of protective layer, which includes polyamide and polyurethane. This is the so-called pural, which is applied to a steel sheet with a thickness of 50 microns. Such materials produced using this technology are highly resistant to temperature extremes, ultraviolet radiation and other negative indicators.

The advantage of the polymer coating is that it can be given any shade in accordance with the RAL table. And this allows you to give a certain style to the fence, selecting it, for example, to match the shade of the roof, walls of the house, or simply fit into the surrounding environment. Based on the specified features of the production of a sheet of corrugated board, it becomes clear that not only the thickness of the metal itself, but also the thickness of the applied coating affects the main characteristics. This is what the thickness of the profiled sheet for the fence specifically affects.

- The thickness and type of coating affect how long the sheet will last in the finished product, specifically in the fence.

- If we talk directly about the thickness of the steel sheet, which is extruded into the profile, then the value of this parameter directly affects the rigidity of the entire structure of the fence. This is an important indicator, since the so-called mechanical load resistance coefficient, including gusts of wind acting on the plane of the fence, depends on it. Due to the existing "windage", the sheet should not bend under the influence of any impact. Therefore, if you want the fence to serve as long as possible, you should choose a thicker corrugated board.

Standard options

After making sure that certain indicators of the corrugated board for the fence are important during its operation, it is worth considering all the options that are presented on the construction market.

- The product, the thickness of which is 0.35 mm, is used to create a temporary fence of a construction site or to fence off an area from a gust of wind. A similar material is also suitable in order to create a fence in the country. In this case, there is no need to talk about a high level of security and a too long service life, but the price for such material is lower than for thicker sheets.

- Profiled sheeting, the sheet thickness of which ranges from 0.4 to 0.45 mm, is most often used to enclose the territory of a private house or industrial facility. This is the one that is most commonly used as it provides optimal protection in combination with price. Suitable for those areas where there are no strong gusts of wind or the building is surrounded by trees or neighboring buildings.

- For an increased level of protection and the longest possible service life, the sheet thickness should be above the 0.5 mm mark. It is recommended to choose this option in those territories that are located in open areas, where strong enough winds blow in different seasons.

Thus, the recommended sheet thickness for rational use and creating a sufficiently stable fence is in the range from 0.4 to 0.5 mm.

It happens that users make unreasonable choices. It is due to the fact that, for example, a sheet with a thickness of 0.5 mm and 0.4 mm will have the same resistance to wind. Therefore, when you need to save money, you can choose a smaller thickness of corrugated board. In this case, it is necessary to pay attention to the useful area, as well as the appearance of the corrugated board. And you should choose the option that is suitable for each specific case.

If you need to build a standard fence, then in most cases the following recommendations of specialists are used.

- A fence with a height not exceeding 2 m is attached to 2 standard logs. In this case, it is better to use C8 sheet, the thickness of the steel sheet in which is 0.5 mm.

- If the fence is being erected with a height of 2 meters or more, then a standard sheet of corrugated board with a thickness of 0.4 mm and marked C8 is used. It is still better to mount it on 3 lags.

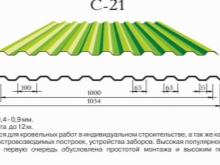

- If you use corrugated board marked C21, the thickness of which is 0.5 mm, then you can attach it to 2 logs. But only on condition that the height of the structure does not exceed 2 m.

Such calculations, from the point of view of the construction of a structure, are important when choosing one or another type of corrugated board, since they provide the necessary rigidity of the structure and a given period of its operation without collapsing or subsidence of individual elements of the fence.

Which one can you choose?

When it is necessary to build a fence, it is better to listen to the following expert advice on how to choose such materials and what to look for during installation.

- The optimum metal thickness is 0.5 mm. The most commonly used material grade is C8. For such a sheet, the thickness can vary from 0.5 to 0.8 mm, and the width of the sheet is 1.2 m.But it should be borne in mind that the working width will be slightly smaller, since part of this parameter will go under the mount in the rack. Thus, the width of one section span is 1.15 m. These profile parameters are sufficient to ensure the reliability of the structure in terms of mechanical strength and durability of operation.

- As for the length of the sheet, it can be different, and each owner selects it based on their own needs and future design features of the fence structure. On the market, you can find the lengths of profiled sheets in the following size range - 1.06 m, 1.2 m, 2.3 m, 6 m. But this does not mean that the fence sections will have to be taken necessarily based on these parameters. You can cut any length, having previously agreed with the customer.

- For a fence with a height of 2 m or more, it is necessary to make 3 fixing lags. If the height is less than this parameter, then the fastening is carried out by 2 logs. In any case, it is necessary to ensure the minimum rigidity so that the structure does not bend or warp under the influence of mechanical load or under its own weight.

Professionals will be able to determine the load on the fence sheet. Therefore, when erecting such a structure, it is worth resorting to their help. In addition, it is they who will be able to install the barrier structure, observing the entire sequence of technology. This means that the owner will be able, without worrying and without reworking the structure, to enjoy safety and sound appearance.

The comment was sent successfully.